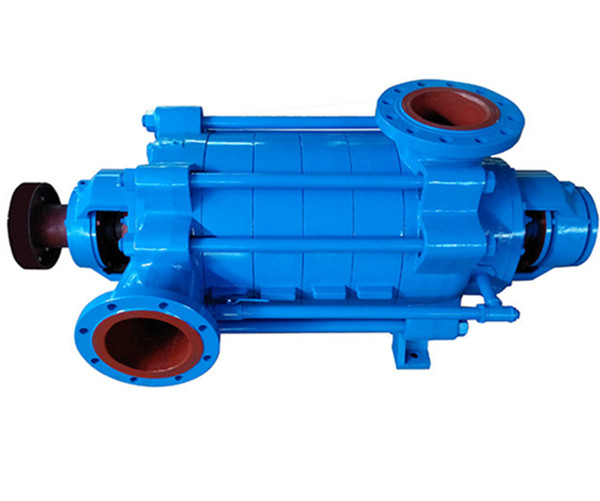

China Wholesale Horizontal Multistage Water Pump Quotes Pricelist - IS Horizontal Centrifugal Water Pump – Boda

China Wholesale Horizontal Multistage Water Pump Quotes Pricelist - IS Horizontal Centrifugal Water Pump – Boda Detail:

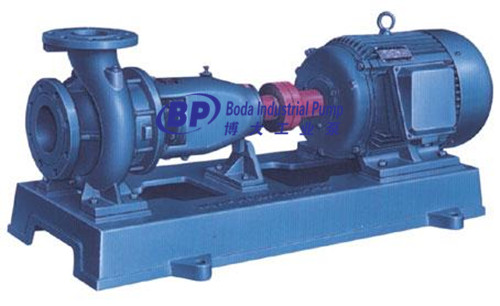

IS, IR horizontal water centrifugal pump use and characteristics

IS, IR-type pump is a horizontal single-stage single-suction water centrifugal pump for industrial and agricultural and urban, drainage, fire water and so on.

For the delivery of water and physical and chemical properties similar to the water does not contain solid particles of liquid. It is widely applied to industrial and agricultural and urban, drainage, fire water and so on.

IS, IR-type pump according to the international standard IS02858 provides the performance and size of the design, its technical standards are closer to the international standard, reaching the international advanced level. It is China’s promotion of energy-saving pump products.

The pump structure is simple, reliable performance, small size, light weight, good anti-cavitation performance, low power consumption, easy maintenance and use.

IS, IR-type pump wide versatility, a full range of 140 kinds of specifications, but only four kinds of shaft; the same specifications of the shaft, bearings, shaft seal, can be interchangeable; full range of pump suspension only four.

Pump speed is divided into 2900 and 1450r / min two.

Maximum operating temperature: 80 ℃

Allow the suction pipe pressure 0.3MPa, the maximum pump pressure of 1.6MPa.

IS, IR horizontal water centrifugal pump structural description

The pump is open, open the pump cover and the impeller without removing the suction and discharge piping. The suspension is fitted with two ball bearings, lubricated with machine oil or grease. The pump is driven directly by the motor through a flexible coupling. The vortex chamber, the foot, the water inlet flange and the water outlet flange are cast as a whole.

IS, IR horizontal water centrifugal pump structure diagram

IS, IR-type pump according to the national standard ISO2858 the performance and size of the design,Mainly by the pump (1), pump cover (2), impeller (3), shaft (4), sealing ring (5), sleeve and suspension bearing parts (12) and so on.

IS, IR pump part of the pump and cover, is from the back of the impeller, that is commonly referred to as the back door structure. The advantage is easy to repair, maintenance does not move the pump body, suction pipe, discharge pipes and motors, just remove the coupling of the middle coupling, you can exit the rotor parts, for maintenance.

Pump housing (ie, pump and pump cover) into the pump of the studio, impeller, shaft and rolling bearings for the recorded rotor. The suspension bearing part supports the rotor part of the pump, and the rolling bearing receives the radial force and axial force of the pump.

In order to balance the axial force of the pump, most of the pump before and after the impeller is equipped with a seal ring, and in the impeller rear cover with a balance hole, because some pump axial force is not large, the impeller is not set on the back of the seal ring and Balance hole.

The axial seal ring of the pump is composed of packing gripper (9), packing ring (10), and packing (11), etc., to prevent air intake or a large number of water leakage. If the impeller of the pump is balanced, the cavity with the soft packing is connected with the impeller inlet. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to enter the air along the surface of the sleeve. Therefore, The small holes in the pump cover draw the pressure in the pump chamber to the fill ring to seal. Pump impeller if there is no balance hole, because the impeller back of the liquid pressure is greater than the atmospheric pressure, and therefore there is no leakage problem, it can not fill the packing ring.

In order to avoid shaft damage, the shaft through the packing cavity with the shaft cover protection, between the sleeve and the shaft is equipped with 0-shaped seal to prevent the intake or leakage along the mating surface.

The pump is driven by an extended elastic coupling to the motor. The direction of rotation of the pump, from the drive side, for the clockwise rotation.

1 pump body 2 pump cover 3 impeller 4-axis 5 seal ring 6 impeller nut 7 stop washer 8 sleeve 9 packing gland 10 packing ring 11 packing 12 suspension bearing parts

IS, IR horizontal water centrifugal pump performance parameter table

First, the assembly and disassembly

The pump should be installed before the first check whether the impact of assembly parts of the defects, and scrub clean before assembly.

1, in advance can be around the connection bolts, wire plug, etc. were tightened in the corresponding parts.

2, in advance can be 0-shaped seals, paper mats, blankets, etc. were placed in the corresponding parts.

3, in advance can be sealed ring and packing, packing ring, packing gland, etc. in turn into the pump cover.

4, the rolling bearing mounted on the shaft, and then installed into the suspension, and then close the gland, press the rolling bearing, and in the shaft on the connection bolt.

5, the shaft set on the shaft, then the pump cover installed in the suspension, and then the impeller, stop pad Wai. Impeller nuts and other equipment and tighten. Finally, the above components into the pump body, and tighten the pump, pump cover on the connection bolts.

In the above assembly process, some small pieces such as flat key, file oil pan, file water ring sleeve 0-shaped seal Wai, etc. easy to remove or install the order, should pay special attention.

The pump disassembly sequence can basically be carried out in reverse of the assembly sequence.

Second, the installation

The installation of the pump has an important effect on the operation and life of the pump, so the installation and calibration must be carried out carefully. Pump shape and installation dimensions.

1, installation and calibration:

1) Remove the greases and dirt from the base and place the base on the foundation.

2) Check the level of the base with the level, allowing leveling with wedge.

3) Pour the base and anchor bolts with cement.

4) After the cement is dry, check whether the hole of the base and the anchor bolt is loose, and then tighten the anchor bolts and re-check the level.

5) Clean the base of the support plane, pump feet and motor feet of the plane, and the water recording and motor installed to the base up.

6) between the coupling should maintain a certain gap, check the pump shaft and motor shaft centerline is consistent, can be adjusted with a thin gasket to make it concentric.

Measuring the coupling of the outer circle up and down, the gap between the left and right shall not exceed 0.1mm, the balance between the two sides of the maximum and minimum spacing of the gap shall not exceed 0.3mm

2, installation instructions:

1) Pump installation height, pipe length, diameter, flow rate should be calculated, and strive to reduce unnecessary losses.

2) long-distance transport should take a larger diameter, the pump pipe should have its own stent, do not allow the weight of the pipeline added to the pump, to avoid the pump crushed.

3) Discharge piping If fitted with check valve should be installed outside the gate valve.

Third, start to stop and run

1, start:

1) should determine the direction of rotation of the motor is correct, the pump is flexible operation.

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of China Wholesale Horizontal Multistage Water Pump Quotes Pricelist - IS Horizontal Centrifugal Water Pump – Boda , The product will supply to all over the world, such as: Honduras, Poland, luzern, The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

We have been looking for a professional and responsible supplier, and now we find it.