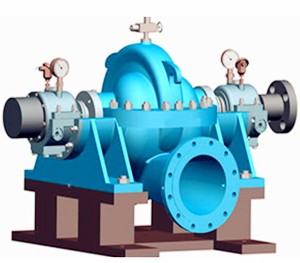

MS پمپ سانتریفیوژ دو برابر مکش

توضیحات پمپ:

MS Type Pump سری S از تجدید محصولات با انرژی کارآمد است که به طور گسترده در آبرسانی و فاضلاب شهری مدرن ، تولید برق ، مصرف آب فرآیند صنعتی ، فشرده سازی ، سیستم های آبیاری و مهندسی هیدرولیک ، مهندسی پتروشیمی و غیره مورد استفاده قرار می گیرد.

MS Type Pump مشخصات استاندارد ملی را برای طراحی ، سریال سازی آن ، استاندارد سازی ، درجه بالایی از تعمیم ، عملکرد برتر ، عملکرد پایدار ، ایمن و قابل اعتماد اتخاذ می کند. سازه های جدید در طراحی ، آسان برای نگهداری ، تعمیر و نگهداری استفاده می شوند. معرفی مطالب جدید ممکن است چندین رسانه برای تحویل کاربرد داشته باشد.

پارامترهای اصلی عملکرد

| قطر خروجی پمپ ظرفیت سر درجه حرارت پارامتر جامد فشار مجاز | DN: 100 ~ 1200mm س: 22392m3 70 ~ 70 ح: 8 ~ 150 متر t: -20 ℃ ~ 200 80mg/l ≤4mpa |

شرح نوع پمپ

به عنوان مثال 500ms35a-lm (f 、 y) -j

500 قطر ورودی (میلی متر)

MS Single Stage Suncation Succation ، Pump Case Case Split گریز از مرکز

35 سر (متر)

قطر بیرونی تغییر یافته پروانه (قطر حداکثر بدون علامت)

نوع عمودی L

m-anti-frication

هم زمان با همبستگی

y-anti

سرعت j-pump تغییر کرد (سرعت را بدون علامت حفظ کنید)

برنامه پشتیبانی پمپ

|

قسمت | برنامه پشتیبانی پمپ a | برنامه پشتیبانی پمپ q | برنامه پشتیبانی پمپ ب | برنامه پشتیبانی پمپ S | |||

| 1 | 2 | 1 | 2 | 3 | |||

|

پوشش پمپ | خاکستری خاکستری |

چدن چدن |

چدن چدن | فولاد ضد زنگ کربن فوق العاده کم | کروم Ni-Cr چدن | چدن چدن | فولاد ضد زنگ |

| پیشرونده | آهن ریخته گری خاکستری | فولاد | فولاد ضد زنگ | Duplex SS | برنز | برنز | برنز |

| شفت | #45 فولاد | #45 فولاد | فولاد ضد زنگ | Duplex SS | 2CRL3 | 2CRL3 | 2CRL3 |

| آستین شفت | #45 فولاد | #45 فولاد | فولاد ضد زنگ | فولاد ضد زنگ کربن فوق العاده کم |

lcrl8ni9ti |

lcrl8ni9ti |

lcrl8ni9ti |

| حلقه پوشیدن | آهن ریخته گری خاکستری |

فولاد | فولاد | Duplex SS | برنز | برنز | برنز |

|

خدمات |

برای آب خالص و کاربردهای مقاومت پایین تر |

برای کاربردهای قدرت بالا آب خالص | برای رسانه هایی با ناخالصی های محکم تر pH <6 خوردگی شیمیایی و برای کاربردهای با استحکام بالا |

پمپ آب دریا | |||

| این تنظیمات توسط سازنده توصیه می شود ، مشتریان می توانند مواد خود را با توجه به نیازهای خاص تغییر دهند | |||||||

طراحی ساخت و ساز من

طراحی ساخت و ساز II

ویژگی ساختار

1. ساختار پوشش: ساختار باز در محوری ، ورودی و خروجی پمپ هر دو روی بدن پمپ و در همان صفحه عمود بر محور. لوله ها و تعمیر آسان (هنگام تعمیر ، بدون از بین بردن ورودی و خروجی لوله ها و موتور) قسمت های پمپ و قطعات روتور را باز کنید).

2. ساختار روتور: با استفاده از ترتیب متقارن برگهای آن ، پروانه دو نفری را اتخاذ کنید تا اثر نیروی شعاعی را متعادل کنید. پروانه روی شافت که به هر دو طرف آستین شافت و مهره آستین متکی است ، با تنظیم دقیق مهره آستین ، موقعیت محوری را به طور دقیق تراز کنید. هر دو انتهای ساختار پشتیبانی شافت ، موتور را مستقیماً از طریق اتصال پین الاستیک متصل می کنند و به طور موثری تلفات مکانیکی را کاهش می دهند. بلبرینگ های توپ شیار عمیق و روغن کاری گریس عملکرد صاف را بیمه می کنند.

ساختار گرداب: بدنه پمپ ، پوشش پمپ و پروانه محفظه مکش و محفظه فشار آب را تشکیل می دهد. برای کاهش نشت آب از محفظه فشار آب به محفظه مکش ، یک حلقه مهر و موم را بین محفظه مکش و محفظه فشار آب نصب کنید که باعث کاهش ظرفیت تلفات می شود ، در حالی که موثر از بدن پمپ محافظت می کند و عمر مورد پمپ را افزایش می دهد. در داخل و خارج از فلنج ، نصب سوراخ مارپیچی برای سنجهای خلاء و فشار را رزرو کرده است. در قسمت پایینی داخل و خارج از فلنج ، سوراخ مارپیچی زهکشی برای دسترسی آسان به سیستم کنترل اتوماسیون.

4. ساختار مهر و موم شافت: مهر و موم های بسته بندی و مهر و موم های مکانیکی وجود دارد ، همچنین ممکن است با توجه به الزامات ویژه ، مهر و موم بسته بندی نرم را اتخاذ کند. بسته به خاصیت رسانه ، آب آب آب (آب شستشو) می تواند از آب محفظه فشار یا آب تأمین خارجی استفاده کند.

داده های فنی

| نوع | ظرفیت | سر | سرعت |

شفت قدرت | نیروی حرکتی | عارضه | NPSH | ساختاری شکل | ||

| (m³/h | (L/S | (م | (r/min | (kw | (kw | (٪) | (م | |||

| 150ms50 |

| 130 160 220 | 36.1 44.4 61.1 | 52 50 40 | 2980 | 25.3 27.3 31.1 | 37 | 72.9 80 77.2 | 3.9 | نقاشی ساختار من |

| A | 112 144 180 | 31.1 40 50 | 43.8 40 35 | 2980 | 18.5 20.9 24.5 | 30 | 72 75 70 | 3.9 | ||

| B | 103 133 160 | 28.6 36.9 44.4 | 38 36 32 | 2980 | 17.2 18.6 19.4 | 22 | 65 70 72 | 3.9 | ||

| 150ms78 |

| 126 160 198 | 35 44.4 55 | 84 78 70 | 2980 | 40 45 51 | 55 | 72 75 74 | 5.9 | |

| A | 112 144 180 | 31.1 40 50 | 67 62 55 | 2980 | 30 33.8 33.5 | 45 | 68 72 70 | 5.9 | ||

| 150ms97 |

| 126 180 216 | 35 50 60 | 104 97 87 | 2980 | 49 59 64 | 75 | 73 80 79 | 3.8 | |

| A | 119 170 204 | 33 47.2 56.6 | 91 85 76 | 2980 | 42 50 55 | 75 | 70 78 77 | 3.7 | ||

| J | 72 90 108 | 20 25 30 | 24 22.5 20 | 1480 | 6.5 7.5 8.5 | 11 | 73 74 70 | 2.7 | ||

| 200ms42 |

| 216 280 342 | 60 77.7 95 | 48 42 35 | 2980 | 34.8 38.1 40.2 | 55 | 81 84.2 81 | 5.4 | |

| A | 198 270 310 | 55 75 86.1 | 43 36 31 | 2980 | 30.5 33.1 34.4 | 37 | 76 80 76 | 5.4 | ||

| 200ms63 |

| 216 280 351 | 60 77.7 97.5 | 69 63 50 | 2980 | 54.8 58.3 66.4 | 75 | 74 82.7 72 | 5.4 | |

| A | 180 270 324 | 50 75 90 | 54.5 46 37.5 | 2980 | 41.1 45.1 47.3 | 55 | 70 75 70 | 5.4 | ||

| 200MS95 |

| 183 280 324 | 50.8 77.7 90 | 103 95 85 | 2980 | 83.1 91.7 100 | 110 | 62 79.2 75 | 4.7 | |

| A | 198 270 310 | 55 75 86.1 | 94 87 80 | 2980 | 74.5 85.5 91.1 | 110 | 68 75 74 | 4.5 | ||

| 250ms14 |

| 360 485 576 | 100 134.7 160 | 17.5 14 11 | 1480 | 21.4 21.5 22.1 | 30 | 80 85.8 78 | 3.2 | |

| A | 320 430 504 | 88.8 119.4 140 | 13.7 11 8.6 | 1480 | 15.4 15.8 15.8 | 22 | 78 82 75 | 3.2 | ||

| 250ms24 |

| 360 485 576 | 100 134.7 160 | 27 24 19 | 1480 | 33.1 36.9 36.4 | 55 | 80 85.8 82 | 3.5 | |

| A | 342 414 482 | 95 115 133.8 | 22.2 20.3 17.4 | 1480 | 25.8 27.6 28.6 | 30 | 80 83 80 | 3.5 | ||

| نوع | ظرفیت | سر | سرعت | شفت قدرت | نیروی حرکتی | عارضه | NPSH | ساختاری شکل | ||

| (m³/h | (L/S | (م | (r/min | (kw | (kw | (٪) | (م | |||

| 250ms39 |

| 360 485 612 | 100 134.7 170 | 42.5 39 32.9 | 1480 | 54.8 61.5 68.6 | 75 | 76 84 79 | 3.2 | نقاشی ساختار من |

| A | 324 468 576 | 90 130 160 | 35.5 30.5 25 | 1480 | 42.5 49.3 50.9 | 55 | 74 79 77 | 3.2 | ||

| 250ms65 |

| 360 485 612 | 100 134.7 170 | 71 65 56 | 1480 | 92.8 109 129.6 | 132 | 75 79 72 | 6.7 | |

| A | 338 462 535 | 93.8 128.3 148.6 | 60 53 49 | 1480 | 73.6 84.4 95.2 | 110 | 74 77 75 | 6.7 | ||

| 250ms110 |

| 400 545 600 | 111.1 151.3 166.6 | 115 110 102.4 | 1480 | 169 206.6 217 | 250 | 74 79 77 | 2.3 | |

| 300ms12 |

| 612 790 900 | 170 219.4 250 | 14.5 11.25 10 | 1480 | 30.2 31.1 33.1 | 37 | 80 85 74 | 5.8 | |

| A | 515 675 781 | 143 187.5 216.9 | 11.5 9.7 8.5 | 1470 | 22.1 22.9 23.8 | 30 | 72 78 76 | 5.8 | ||

| 300ms19 |

| 612 790 935 | 170 219.4 259.7 | 22 19 14 | 1480 | 45.9 47 47.6 | 55 | 80 87 75 | 5.8 | |

| A | 485 693 798 | 134.7 192.5 221.6 | 18.5 14.8 12.1 | 1480 | 34.4 34.9 35.1 | 45 | 71 80 75 | 5.8 | ||

| 300ms32 |

| 612 790 960 | 170 219.4 266.6 | 38 32 29 | 1480 | 76.2 79.2 95 | 110 | 83 87 80 | 5.8 | |

| A | 537 702 720 | 149.1 195 200 | 29.5 24.7 22.8 | 1480 | 53.9 56.2 62.9 | 75 | 80 84 78 | 5.8 | ||

| 300ms58 |

| 576 790 972 | 160 219.4 270 | 65 58 50 | 1480 | 136 148.5 165.5 | 185 | 75 84 80 | 5.8 | |

| A | 529 720 893 | 146.9 200 248 | 55 49 42 | 1480 | 99.2 118.6 131 | 160 | 79 81 78 | 5.8 | ||

| B | 504 684 835 | 140 190 231.9 | 47.2 43 37 | 1480 | 88.8 100 108 | 132 | 73 90 78 | 5.8 | ||

| 300MS90 |

| 590 790 936 | 163.8 219.4 260 | 93 90 82 | 1480 | 202 242 279 | 315 | 74 80 75 | 5.8 | |

| A | 576 756 918 | 160 210 255 | 86 78 70 | 1480 | 190 217 247 | 280 | 71 74 71 | 5.8 | ||

| B | 540 720 900 | 150 200 250 | 72 67 57 | 1480 | 151 180 200 | 220 | 70 73 70 | 5.8 | ||

| نوع | ظرفیت | سر | سرعت | شفت قدرت | نیروی حرکتی | عارضه | NPSH | ساختاری شکل | ||

| (m³/h | (L/S | (م | (r/min | (kw | (kw | (٪) | (م | |||

| 350ms16 |

| 972 1260 1440 | 270 350 400 | 20 16 13.4 | 1480 | 64 64.5 71 | 75 | 83 86 74 | 5.3 | نقاشی ساختار من |

| A | 800 967 1167 | 222.2 268.6 324.1 | 13.7 11.5 8.6 | 1480 | 40.3 38.8 39 | 55 | 74 78 70 | 5.3 | ||

| 350ms26 |

| 972 1260 1440 | 270 350 400 | 32 26 22 | 1480 | 99.7 101.5 105 | 132 | 85 88 82 | 5.3 | |

| A | 843 1088 1264 | 234.1 302.2 351.1 | 24.7 20.4 15.7 | 1480 | 70.9 72.8 74 | 90 | 80 83 73 | 5.3 | ||

| 350ms44 |

| 972 1260 1476 | 270 350 410 | 50 44 37 | 1480 | 164 177.6 189 | 220 | 81 87 79 | 5.3 | |

| A | 876 1260 1476 | 243.3 350 410 | 42 37 31 | 1480 | 125.2 151.1 155.8 | 200 | 80 84 80 | 5.3 | ||

| 350ms75 |

| 972 1260 1440 | 270 350 400 | 80 75 65 | 1480 | 271 304 349 | 355 | 78 85 80 | 5.3 | |

| A | 900 1170 1332 | 250 325 370 | 70 65 56 | 1480 | 220 247 257 | 280 | 78 84 79 | 5.3 | ||

| B | 813 1060 1202 | 225.8 294.4 333.8 | 57 53 45.8 | 1480 | 168 187 195 | 220 | 75 82 77 | 5.3 | ||

| 350ms125 |

| 850 1260 1660 | 236.1 350 461.1 | 140 125 100 | 1480 | 462 531 623 | 710 | 70 81 72.5 | 5.3 | |

| A | 787 1157 1538 | 218.6 321.3 427.2 | 120 107 86 | 1480 | 367 432 515 | 560 | 70 78 70 | 5.3 | ||

| B | 697 1027 1363 | 193.6 285.2 378.6 | 94 84 67 | 1480 | 255 305 343 | 400 | 70 77 72.5 | 5.3 | ||

| 500ms13 |

| 1620 2020 2340 | 450 561.1 650 | 15 13 10.4 | 980 | 83.8 86.2 82.8 | 110 | 79 83 80 | 5.7 | |

| 500ms22 |

| 1620 2020 2340 | 450 561.1 650 | 24.5 22 19.4 | 980 | 140.4 144.1 145.5 | 185 | 77 84 85 | 5.2 | |

| A | 1400 1746 2020 | 388.8 485 561.1 | 20 17 14 | 980 | 103 101 93.9 | 132 | 74 80 82 | 5.2 | ||

| 500ms35 |

| 1620 2020 2340 | 450 561.1 650 | 40 35 28 | 980 | 207.6 219 209.9 | 280 | 85 88 85 | 5.8 | |

| A | 1400 1746 2020 | 388.8 485 561.1 | 31 27 21 | 980 | 144 151 138 | 220 | 82 85 84 | 5.8 | ||

| نوع | ظرفیت | سر | سرعت | شفت قدرت | نیروی حرکتی | عارضه | NPSH | ساختاری شکل | ||

| (m³/h | (L/S | (م | (r/min | (kw | (kw | (٪) | (م | |||

| 500ms59 |

| 1620 2020 2340 | 450 561.1 650 | 68 59 47 | 980 | 379.7 391 374.4 | 450 | 79 83 80 | 4.5 | نقاشی ساختار من |

| A | 1500 1872 2170 | 416.6 520 602.7 | 57 49 39 | 980 | 315 333 320 | 400 | 74 75 72 | 4.5 | ||

| B | 1400 1746 2020 | 388.8 485 561.1 | 46 40 32 | 980 | 240.2 257 247.9 | 315 | 73 74 71 | 4.5 | ||

| 500ms98 |

| 1620 2020 2340 | 450 561.1 650 | 114 98 79 | 980 | 644.8 678 68.3 | 800 | 78 79.5 74 | 4 | |

| A | 1500 1872 2170 | 416.6 520 602.7 | 96 83 67 | 980 | 509.3 540 542.4 | 630 | 77 78.5 73 | 4 | ||

| B | 1400 1746 2020 | 388.8 485 561.1 | 86 74 59 | 980 | 431.4 452 432.8 | 560 | 76 78 75 | 4 | ||

| 600ms22 |

| 2536 3241 3804 | 704.4 900.2 1056.6 | 27.6 22 18 | 980 | 226.8 231.8 232.1 | 250 | 86 88 79 | 7.5 | |

| 600ms32 |

| 2700 3240 3600 | 750 900 1000 | 33.5 32 26 | 980 | 291 317 298 | 400 | 85 89 84 | 7.5 | |

| A | 2520 3000 3165 | 700 833.3 879.1 | 25.5 23 19.2 | 980 | 205.8 211 196.9 | 250 | 85 89 84 | 7.5 | ||

| 600ms47 |

| 2160 3170 3600 | 600 880.5 1000 | 56.6 47 40.5 | 980 | 415.4 455.9 461.7 | 560 | 80 88 86 | 7.5 | |

| A | 2400 2920 3500 | 666.6 811.1 972.2 | 45 42 35 | 980 | 352.5 380 402.2 | 500 | 83.5 88 83 | 7.4 | ||

| 600ms75 |

| 2592 3060 3600 | 720 850 1000 | 78 75 69 | 980 | 644.3 694.4 760 | 900 | 87 88 80 | 8.7 | |

| A | 2338 3084 3248 | 649.4 856.6 902.2 | 63.5 57.8 56.2 | 980 | 467 539 552 | 710 | 85.5 90 89 | 7.3 | ||

| 600ms100 |

| 2592 3240 3888 | 720 900 1080 | 103 100 96 | 980 | 870 1003 1100 | 1250 | 80 88 89 | 7.2 | |

| A | 2352 2940 3528 | 653.3 816.6 980 | 91 87.5 84 | 980 | 620 710 800 | 900 | 80 88 86 | 6.8 | ||

| 700ms24 |

| 3840 4800 5760 | 1066.6 1333.3 1600 | 31 24 18 | 980 | 395 352.5 340 | 400 | 81 89 82 | 8.6 | نقاشی ساختار II |

| 700ms35 |

| 3840 4800 5760 | 1066.6 1333.3 1600 | 42 36 28 | 980 | 522.9 580.5 630.2 | 630 | 86 90 81 | 8.6 | |

| A | 3600 4500 5400 | 1000 1250 1500 | 38 32.5 24 | 980 | 447.9 480.9 530.5 | 500 | 85 89 80 | 8.4 | ||

| نوع | ظرفیت | سر | سرعت | شفت قدرت | نیروی حرکتی | عارضه | NPSH | ساختاری شکل | ||

| (m³/h | (L/S | (م | (r/min | (kw | (kw | (٪) | (م | |||

| 700ms56 |

| 3840 4800 5760 | 1066.6 1333.3 1600 | 64 56 47 | 980 | 770 813.4 910 | 900 | 87 90 83 | 8.6 | نقاشی ساختار II |

| A | 3400 4500 5400 | 944.4 1250 1500 | 56 51 39 | 980 | 620 702.2 755 | 800 | 84 89 80 | 8.4 | ||

| 700ms90 |

| 4000 4700 5500 | 1111.1 1305.5 1527.7 | 97 90 77 | 980 | 1201 1281 1358 | 1600 | 88 90 85 | 9.4 | |

| 700ms135 |

| 2720 3400 4080 | 755.5 944.4 1133.3 | 137 135 130 | 800 | 1335.3 1524.4 1699.3 | 1765 | 76 82 87 | 5.7 | |

| 800ms22 |

| 4320 5500 6840 | 1200 1527.7 1900 | 25 22 19 | 730 | 358 370 385 | 450 | 82 89 86 | 7 | |

| 800ms24 |

| 5250 7000 8400 | 1458.3 1944.4 2333.3 | 27.5 24 200 | 730 | 479 506 532 | 560 | 82 90 86 | 8.7 | |

| A | 4840 6250 7740 | 1344.4 1736.1 2150 | 23.6 21 17.2 | 730 | 382 406 429 | 500 | 81.5 88 84.5 | 8.7 | ||

| 800ms32 |

| 4320 5500 6480 | 1200 1527.7 1800 | 35 32 29 | 730 | 502.2 538.5 588.2 | 630 | 82 89 87 | 7.2 | |

| A | 3500 4950 6000 | 972.2 1375 1666.6 | 30 26 23 | 730 | 353 398.3 437 | 500 | 81 90 88 | 7.2 | ||

| 800MS47 |

| 4320 5500 6480 | 1200 1527.7 1800 | 51 47 42 | 730 | 740.7 782.2 842.2 | 900 | 81 90 88 | 7.2 | |

| A | 3500 5070 6000 | 972.2 1408.3 1666.6 | 45 40 36 | 730 | 529.5 620.5 684 | 800 | 81 89 86 | 7.2 | ||

| J | 300 4400 5200 | 83.3 1222.2 1444.4 | 35 30 26 | 590 | 357.4 403.9 428.1 | 450 | 80 89 86 | 7.2 | ||

| 800ms48 |

| 4056 5070 6084 | 1126.6 1408.3 1690 | 57 48.5 39 | 595 | 777 752 734 | 1000 | 85 89 88 | 5.8 | |

| 800ms75 |

| 5920 7360 8075 | 1644.4 2044.4 2243 | 76 72 69 | 740 | 1426 1570 1760 | 1600 | 86 92 89 | 8.4 | |

| A | 4750 6080 6745 | 1319.4 1688.8 1873.6 | 61 58 55 | 740 | 929 1056 1162 | 1400 | 85 91 87 | 7.3 | ||

| B | 4370 5550 6175 | 1213.8 1541.6 1715.2 | 55 52.3 49.5 | 740 | 777 876 965 | 1120 | 84.3 90.3 86.3 | 6.6 | ||

| 800MS80 |

| 5356 6696 8035 | 1487.7 1860 2231.9 | 87 80 72 | 740 | 1540 1603 1720 | 2000 | 86 91 90 | 9 | |

| 900ms23 |

| 6000 7500 9000 | 1666.6 2083.3 2500 | 27.5 23 18 | 730 | 630 610 590 | 630 | 79 86 84 | 7.5 | |