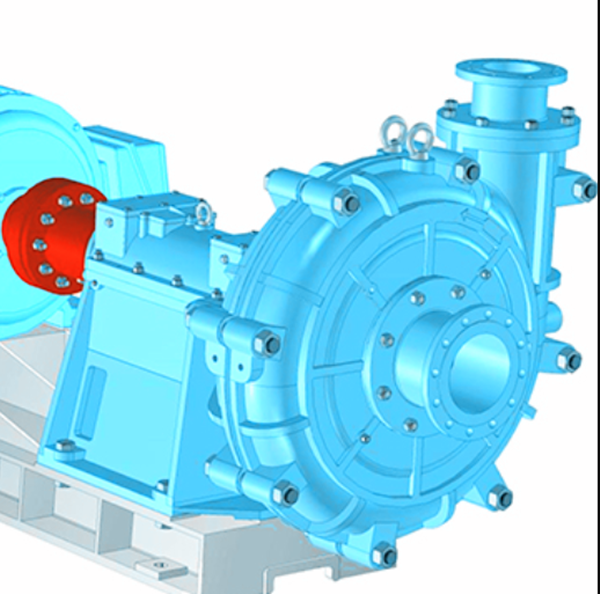

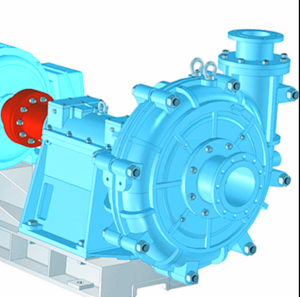

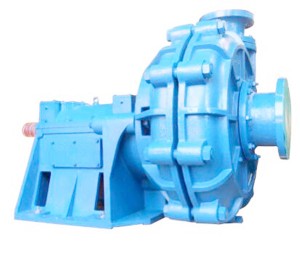

Type ZGB (P) Slurry Pump

Funksje ynlieding:

1. Avansearre hydraulyske prestaasjes, Cad Moderne Untwerp, hege effisjinsje en legere abrasysrate2 breed passaazje, net-stippende en goede prestaasjes fan NPSH.3. Expeller-segel kombineare mei ynpakke segel en meganyske segel binne oannaam om de slurry te garandearjen fan lekkage.4. It fertrouwenûntwerp soarget foar lange MTBF (gemiddelde tiid tusken eveneminten)5. It metryske lager mei oalje smering, ridlike smeer en koelingssystemen soargje foar it dragen om ûnder de legere temperatuer te betsjinjen.

6.De materialen fan wiete dielen hienen de goede prestaasjes fan anty-korroen en anty-korrosje, de pomp kin wurde brûkt om te foarkommen om it te foarkommen dat hy fan 'e korrosjele, sâlt en mist, en mist en mist, en elektrochemysk korrosie.

7.De pomp kin wurde betsjinne yn searje mei multi-poadium binnen tastiene druk. De tastiene maksimale wurkdruk is 3,6 MPA.

De searje pomp hat it foardiel fan ridlike konstruksje, hege effisjinsje, betroubere operaasje en maklik ûnderhâld. It kin breed brûkt wurde foar it behanneljen fan it mingsel befette fan abrase en korrossyf stoffen, METALLY, MET KOLE, KONLIKE MATERIALE ESPENCIAL FOAR ESKIAL FOAR ESKIAL FOAR ELKE EN SLUKGE IN ELKE POWER STATION.

Pumpefunksjes:

1. De searje ZGB (P) Slurry-pomp is fan horizontale, ien-poadsje, ienswapen, Kantileiver, dûbele gefallen, sintrifugale slurrypomp. De pomp draait yn 'e klok fan' e stasjon fan it stasjon.

2. De wiete dielen fan ZGB- en ZGBP-pomp tagelyk kin útwikselber wurde. Harren ôflieding fan it útstallige ynstallaasje binne ien en itselde. Foar it stasjonsdiel fan 'e Series ZGB (P) Slurry-pomp, it horizontale splitspomp mei oalje smering en twa sets fan wetterkoelsystemen binnen en bûten is oannaam. As nedich, koelwetter kin wurde levere. De tariede joint foar koeling wetter en de druk fan it koelwetter kin wurde sjoen yn Tabel 1.

3. Twa soarten skaft-segel -útput sicht kombineare mei ferpakking en meganyske segel binne brûkt foar searje ZGB (P) slurrypomp.

4. De meganyske segel levere mei it útlaad fan hege druk wurdt oanrikkemandearre as de slurry-pomp wurdt betsjinne (twa stadia en boppe twa segelkombineare mei ferpakking wurdt brûkt yn ien poadiumpomp.

Pump Performance Tabel:

|

Model | SPEED N (R / MIN) | Kapasiteit Q (L / S) | Holle H (m) | Max.eff. | NPSH | Skacht Krêft (KW) | Impeller Dia (mm) | Pump gewicht (kg) | Outlet / Inlet (mm) | |

| 65ZGB | 1480 | 31,7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | 390 | 1850 | 65/80 80 | |

| 1280 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.-1.3 | 8.37-5.8 | |||||

| 80ZGB | 1280 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | 80/1 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 1280 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 1280 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31,0-15.4 | 26.1-27.3 | 66.1-48.7 | 1,5-0,8 | 12.0-8.4 | |||||

| 100ZGB | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100/153 | |

| 1280 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2,7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 1280 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 1280 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150zgb | 1280 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3,8-2.7 | 215.0-165.5 | 740 | 3450 | 150/200 | |

| 740 | 151.2-75.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 1280 | 182.4-91.2 | 73.0-77.1 | 77.7-53.3 | 3,3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 1280 | 169.2-84.6 | 61.8-65.2 | 77.7-53.3 | 2,8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| 200ZGB | 1280 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/40 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 1280 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 1280 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2,9-1.1 | 95.6-61.0 | |||||

| 250zgb | 1280 | 400.0-200,0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 1280 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | 700 | ||||

| 740 | 285.7-142.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 1280 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300ZGB | 1280 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300/350 | |

| 740 | 402.7-2-201.3 | 48.1-53.3 | 81.2-68.3 | 3,9-2.0 | 233.9-154.0 | |||||

| 1280 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-45.6 | 81.2-68.3 | 3.4-1,7 | 184.8-116.4 | |||||

| 1280 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |