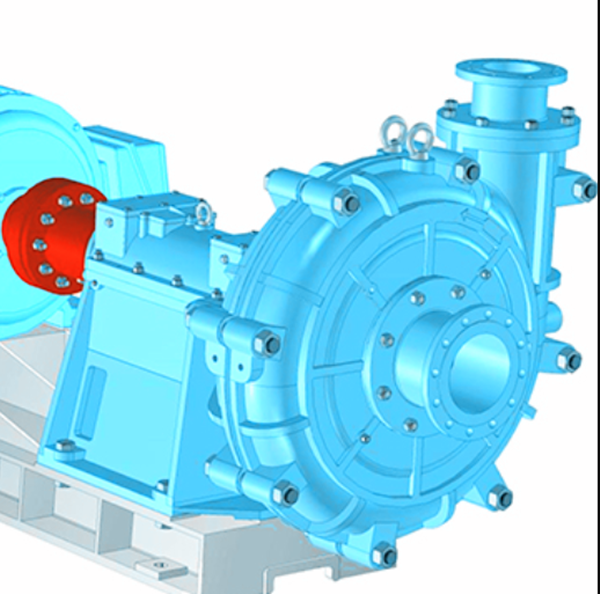

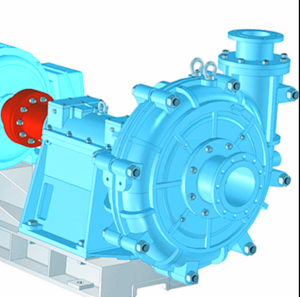

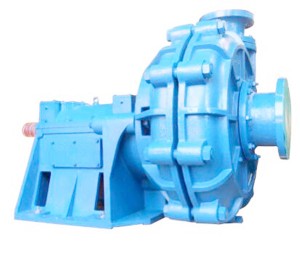

Rubuta ZGB (p) slurry famfo

Gabatarwa Gabatarwa:

12. Tassi mai fadi, wanda ba clogging da kyau na Npsh.3. Develler hatimi hade tare da shirya hatimi da injina na inji don bayar da garantin slurry daga yadudduka.4. Tsarin aminci yana tabbatar da tsawon lokaci mai tsawo tsakanin abubuwan da suka faru)5. A awo awo tare da lubrication mai, mai ma'ana mai amfani da tsarin sanyaya mai sanyaya suna tabbatar da ɗaukar hoto a ƙarƙashin ƙananan zafin jiki.

6.The kayan rigar sassan suna da kyakkyawan aikin anti-sanye da anti-corrose na ruwa-corros don hana shi daga lalata, gishiri da hazo, da lalata lantarki.

7.The famfo za'a iya sarrafa shi a cikin jerin tare da matakai da yawa a cikin matsin lamba. Matsakaicin matsakaiciyar matsin lamba shine 3.6 MPA.

Jerin famfo yana da fa'idar aikin ginin, babban aiki, abin dogara aiki da gyara sauƙi. Ana iya amfani da shi sosai don kula da cakuda da ke ɗauke da cututtukan jini da lalata a cikin wutar lantarki, etan gini da sassan masana'antu na musamman don cire ash da sludge a tashar wutar lantarki.

Fasalin famfo:

1. Jerin ZGB (P) sl slurry famfo shine a kwance, guda-mataki, tsotsa guda, cantilifugal slurry famfo. Famfo mai juyawa a cikin agogo da aka gani daga ƙarshen tuki.

2. Wanke sassan ZGB da ZGBP famfo a cikin babban abin da diamita ɗaya na iya zama mai canzawa. Abubuwan da aka sanya su shigarwa iri ɗaya ne kuma iri ɗaya ne. Ga wani ɓangare na jerin ZGB (P) famfo na slurry, tsage tsaga Frame tare da lubrication mai ciki da kuma tsarin sananniyar ruwa a ciki da waje an karɓa. Idan ya cancanta, ana iya kawo ruwan sanyi. Haɗin gwiwa don sanyaya ruwan sanyi kuma ana iya ganin matsin ruwan sanyaya a cikin Table 1.

3. Abubuwa biyu na hatimin hatimin hatimi wanda aka haɗu da shi da kunshin da aka shirya don jerin gwano (p) famfo.

4. Ana bayar da shawarar da ruwan zarfi tare da babban ruwa mai rufe ruwa lokacin da aka yi amfani da farashin slurry a cikin matakai biyu), da kuma hatimin biyu), da kuma hatimin biyu), da kuma hatimin biyu), da kuma suttura da aka yi amfani da shi a cikin famfo guda ɗaya.

Teburin aikin yi:

|

Abin ƙwatanci | Sauri n (r / min) | Kariyar q (l / s) | Kai H (m) | Max.eff. | Npsh | Mashi Ƙarfi (kw) | Wanda aka yi wa misali Dia (mm) | M nauyi (kg) | Wuta / Inlet (MM) | |

| 65zgb | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | 390 | 1850 | 65/80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| 80zgb | 980 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | 80/100 | |

| 740 | 37.5.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31.0-15.4 | 26.1-17.3 | 66.1-48.7 | 1.5-0.8 | 12.0-8.4 | |||||

| 100ZGB | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100/52 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 980 | 69.5-344.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150zgb | 980 | 200-100 | 85.290.0 | 77.7-53.3 | 3.8-2.7 | 215.0-165.5 | 740 | 3450 | 150/200 | |

| 740 | 151.275.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5.5 | 92.7-71.3 | |||||

| 980 | 182-9-91.2 | 73.0-77.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-444.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.284.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-644.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| 200ZGB | 980 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.81.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 980 | 259.59.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| 250zgb | 980 | 400.000.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378-189.2 | 75.280.6 | 78.2-63.2 | 7.1.0 | 356.7-233.2 | 700 | ||||

| 740 | 285.7-142.9 | 42.9-46.06.06.06.06.06.06.06.06.06.06.06.06.06 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348-6-131.6 | 63.8-68.5.5 | 78.2-63.2 | 5.5-2.5 | 278-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300zgb | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300/350 | |

| 740 | 402.7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-2822.9 | 703 | ||||

| 740 | 372.57-177.9 | 41,45.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |