High-Quality OEM Ahf Foam Froth Slurry Pumps Manufacturers Suppliers - wear-resistant rubber slurry pump – Boda

High-Quality OEM Ahf Foam Froth Slurry Pumps Manufacturers Suppliers - wear-resistant rubber slurry pump – Boda Detail:

Description:

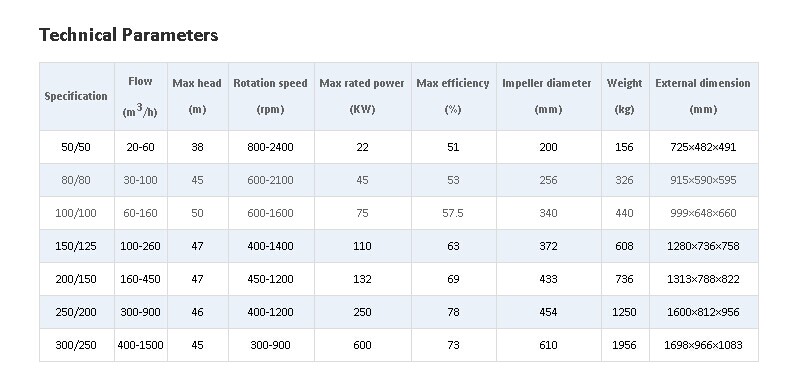

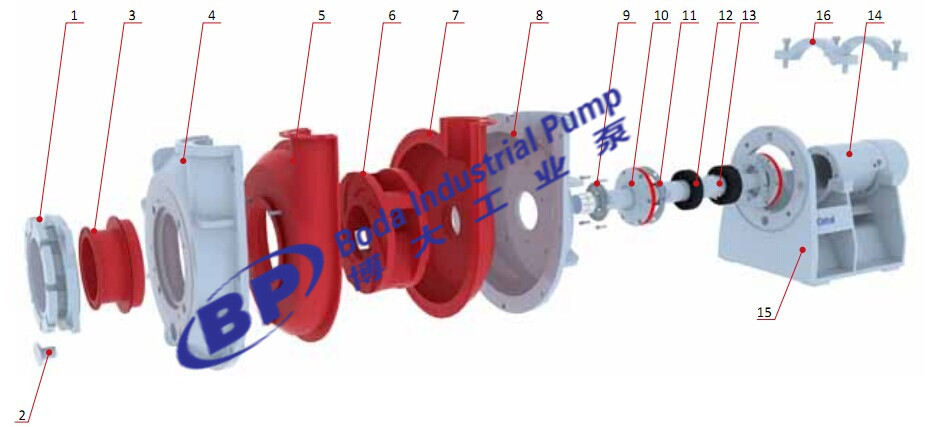

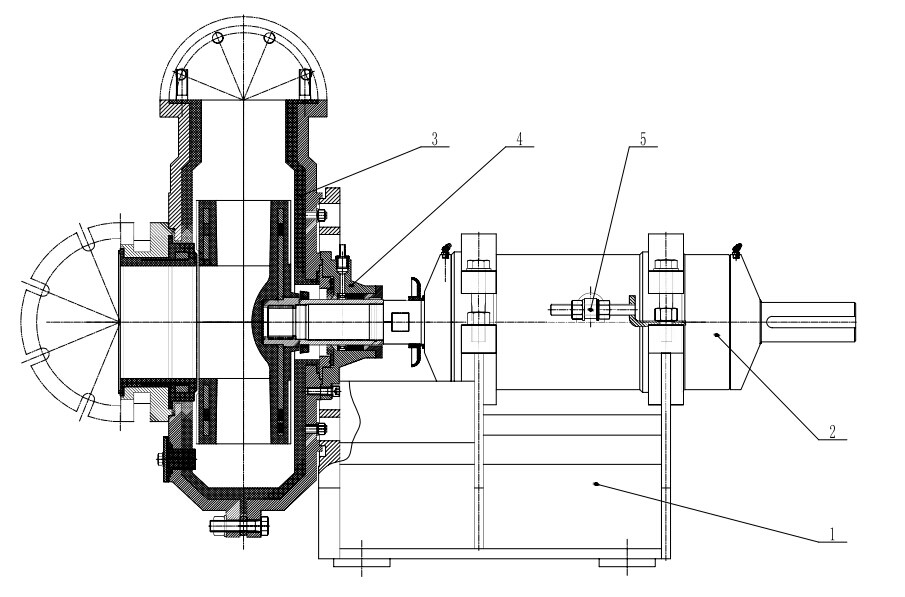

Driven by motor, the pump body and inlet line are filled with liquild before starting the pump. With high-speed rotation, the impeller drives the liquild between the vanes to rotate together. Due to the effect of centrifugal force, the liquild is thrown to the outer edge of impeller from the impeller center with kinetic energy increased.After the liquid entering the pump shell, as the flow channel in the volute type pump shell is gradually enlarged, the liquid velocity is decreased gradually, which makes part of the kinetic energy transform into static energy, therefore the liquid with high pressure is discharged along the outlet. At the same time, the impeller center forms a certain vacuum for that the liquid is thrown out.The pressure on liquid level is higher than that of impeller center, so the liquid in suction pipe will flow into the pump under the action of pressure difference. With the constant rotation of impeller, the liquid is sucked and extruded continuously.

Features:

Based on the outstanding wear resistance of world-famous Boda rubber and the molded rubber flow parts, BPA series of Boda wear-resistant rubber lined pump has absolute authority in terms of wear resistance.It has the features of smooth operation, energy convervation, low noise, cost saving, high efficiency, easy maintenance, and durability. The maximum concentration of pulp delivery should be no more than 60% ( weightometer). The temperature of pulp delivery is among -40- +70 ℃。

Application:

Boda rubber pump is suitable for handling corrosive slurry or fluid containing solid materials, exceeding the scope of application of metal and other types of pumps.Beneficiation-metallurgy plant: Hydrocyclone feeding is grinding ore cycle (including the first stage of grading hydrocyclone); pump delivery, concentration & filtering of tailings, concentrates and intermediate products; all kinds of slurry pump delivery.

Power plant: The delivery of tail ash, slag and coal slurry.

Sand and gravel plant: Sand and gravel transportation, sand and water supply of mining, all kinds of classification and dewatering equipment with remarkable wear resistance by contrast.

Coal preparation plant: Grading, screening and conveying of dense medium; coal slurry transportation.

Chemical plant: The treatments of chemical liquid, acid or base, slurry, and waste water at low and medium temperature.

Water conservancy project: Damming, bed silt displacement, sand and gravel classification, etc.

Paper mill: The treatment of clay slip, paper pulp and waste water.

Ceramic and glass plant: porcelain clay and sand & gravel transportation, hydrocyclones feeding and waste water treatment.

Steel plant: The delivery of slurry, oxide skin, and corrosive liquid.

Special instructions should be offered to us if with oil and chemical.

![]()

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for High-Quality OEM Ahf Foam Froth Slurry Pumps Manufacturers Suppliers - wear-resistant rubber slurry pump – Boda , The product will supply to all over the world, such as: Bogota, Frankfurt, Bandung, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.