Submersible dej twj tso kua mis

QJ Submersible Hluav Taws Xob Twj Rau Cov Khoom Siv Zoo (Nqis Tej Twj)Khoom Piav Qhia

QJ-Hom Submersible twj yog lub cev muaj zog thiab cov taub dej ncaj qha rau hauv cov dej ua haujlwm, nws yog qhov tsim nyog los ntawm cov dej ntws, cov dej ntws, dej thiab lwm yam dej nqa dej: Feem ntau yog rau kev ua liaj ua teb thiab cov dej toj siab ntawm tib neeg thiab tsiaj dej, tab sis kuj rau cov nroog, cov chaw ua haujlwm, qhov chaw ntawm cov dej siv.

QJ submersible siv hluav taws xob twj tso kua mis kom zoo (tob cov kua dej) Nta

1. Lub cev muaj zog, tso dej twj ib, nyas mus rau hauv dej kom khiav, nyab xeeb thiab txhim khu kev qha.

2. Tsis muaj ib qho tshwj xeeb rau cov yeeb nkab zoo thiab cov yeeb nkab dej (piv txwv li cov av hlau kom zoo, cov yeeb nkab zoo, cov yeeb nkab steel, Cov yeeb nkab yas thiab yog li ntawd tuaj yeem ua cov yeeb nkab dej).

3. Txhim kho, siv, yooj yim txij nkawm yooj yim, hneev me, tsis tas yuav muaj tsheb twj tso kua mis.

4. Cov qauv yooj yim, txuag cov khoom raw.

Submarine twj tso kua mis siv cov kev mob yog qhov tsim nyog, kev tswj hwm kom zoo thiab lub neej ntawm kev sib raug zoo ncaj qha.

QJ Submersible siv hluav taws xob twj tso kua mis kom zoo (tob cov kua dej) Conditions ntawm kev siv

QJ-HomSubmersible twj tuaj yeem siv tsis tu ncua raws li cov xwm txheej hauv qab no:

1. Peb-theem AC Fais Fab Ua Haujlwm nrog cov zaus ntsuas ntawm 50Hz thiab ntsuas voltage ntawm 380 ± 5% v.

2. Lub twj tso kua mis yuav tsum qis dua 1 'meter hauv qab cov dej ntws qeeb, tab sis theem dej tob tob yuav tsum tsis pub tshaj 70 metres hauv qab ntawm qib hydrostatic. Qhov qis qis kawg ntawm lub cev muaj zog yog tsawg kawg 1 'meter' sab saud hauv qab dej tob.

3. Dej kub yog feem ntau tsis siab tshaj 20 ℃.

4. Cov dej num zoo: (1) Dej cov ntsiab lus ntawm cov dej tsis siab tshaj 0.01% (qhov hnyav piv);

(2) PH TUS NQE TSHUAJ TSHUAJ NTAWM 6.5 ~ 8.5;

(3) Chloride cov ntsiab lus ntawm tsis ntau tshaj 400 mg / l.

5. Yuav tsum muaj tus nqi zoo, phab ntsa yog tus, tsis muaj qhov zoo stagemed.

QJ Submersible siv hluav taws xob twj tso kua mis kom zoo (kev ua haujlwm tau zoo) cov qauv piav qhia

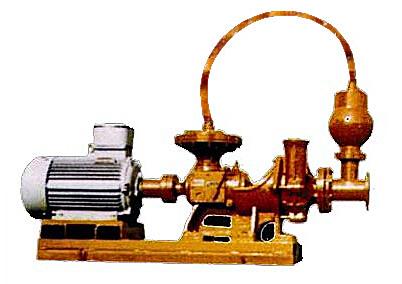

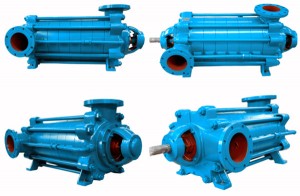

1.qoj-hom submersible twj tso kua mis muaj cov: lub cev muaj dej tawm, lub cev muaj zog (suav nrog cables), cov kav dej mus rau ntawm plaub ntu.

Submersible twj tso kua mis rau ib-SOITION ntsug centrifugal twj tso kua mis: lub cev muaj zog rau lub cev muaj zog, lub cev muaj zog thiab ib lub nruas sib txuas ncaj qha; Nruab nrog cov kev sib txawv ntawm peb lub cable tseem ceeb; Pib cov khoom siv rau cov pa roj teeb sib txawv, cov yeeb nkab dej rau cov yeeb nkab sib txuas, cov twj tso kua mis ntau nrog cov rooj vag.

2. Submersible twj tso kua mis txhua theem ntawm cov baffle yog haum nrog cov roj hmab coj los; Tus illeller yog tsau rau lub twj tso kua mis ncej nrog lub tes tsho thaiv; Lub baffle yog threaded lossis bolted.

3. High-el subsersible twj nrog tus kos valve rau sab qaum, kom tsis txhob poob siab los ntawm kev puas tsuaj rau chav ntsuas.

4. Submarine Tsav Ncej nrog ib labyrinth Sandstration thiab ob tog sib dhos ntawm lub cev pob txha ntim, los tiv thaiv cov kev ntws ntawm cov xuab zeb mus rau lub cev muaj zog.

5. Submersible tsav nrog dej lubricated bearings, qhov qis dua ntawm cov roj hmab siab tswj zaj duab xis, tsim ntawm cov ntxaij, kho qhov siab los ntawm kev hloov kub; Lub cev muaj zog winding nrog polyethylene rwb thaiv tsev, nylon tsho ruaj cov khoom siv dej, tau txuas nrog, siv roj hmab nyoos ib puag txheej. Thiab tom qab ntawd qhwv nrog cov ntaub nyias nyias nplaum nplaum thib 2 txog 3 txheej, sab nraud ntawm cov kab xev roj hmab (tsheb kauj vab) kom tiv thaiv dej Soot.

6. Lub cev muaj zog tau muab ntim, kaw nrog precision nres ntsia liaj qhov rooj thiab qhov hluav taws xob cable.

7. Lub caij nplooj zeeg kawg ntawm lub cev muaj zog muaj lub qhov tso pa tawm, muaj qhov chaw ua rau lub qhov muag, qhov chaw qis ntawm lub qhov dej.

8. Qhov qis dua ntawm lub cev muaj zog nrog cov kabmob sab saud thiab qis dua, thiab nws sib tsoo lub phaj stainless hlau tshuab, nrog cov twj tso kua mis kom nce thiab nqis axial.

QJ Submersible Hluav Taws Xob Twj Rau Cov Khoom Siv Zoo (Nqis Tej Twj)Ua Haujlwm Cov Ntsiab Cai

Ua ntej qhib lub twj tso kua mis, nqus cov yeeb nkab thiab cov twj yuav tsum tau ntim nrog kua. Tom qab lub twj twj tso kua mis tso tawm, lub impeller rotates ntawm kev kub ceev, thiab cov kua rotates nrog cov hniav. Nyob rau hauv kev txiav txim ntawm centrifugal quab yuam, nws yoojyim rau sab nraud thiab cov kua tau maj mam nce los ntawm cov twj tso kua mis expased, tso yeeb nkab tawm. Txij ntawm no, ntawm nruab nrab ntawm cov hniav ntawm qhov chaw ntawm cov kua yog pov tseg ntawm thaj chaw uas tsis muaj huab cua thiab tsis muaj kua dej hauv pas dej ntawm kev txiav txim siab ntawm kev nqus Yeeb nkab rau hauv lub twj tso kua mis, cov kua yog li tom ntej tau nqus los ntawm cov kua dej ua kua thiab txuas mus ntxiv ntws tawm ntawm cov yeeb nkab paug.

QJ Submersible siv hluav taws xob twj tso kua mis kom zoo (tob cov kua dej) use thiab cov yam ntxwv

QJ-Hom Sacrersible twj vov yog raws li cov qauv khoom lag luam hauv teb chaws, kev lag luam siv hauv cov khoom siv hluav taws xob, kev siv dej, toj siab, cov neeg roob, cov tsiaj txhu.

Lub twj tso kua mis muaj QJ submersible twj thiab YQS submersible tsav mus rau ib underwater ua haujlwm hauv qab dej. Nrog cov qauv yooj yim, qhov loj me, lub teeb hnyav, teeb tsa, kev ua haujlwm yooj yim, txhim khu kev qha, zog siv tau thiab lwm yam.

QJR series ntawm cov dej sov-res resistant submersible twj tso kua mis, muaj kev sib sau ua ke nrog rau 100 ° C, yog submerged rau hauv lub qhov dej , Dej yog cov cuab yeej zoo; geothermal yog ib qho ntawm pheej yig, huv si, inexhaustible tshiab lub zog, kev kho mob, kev ua liaj ua teb, kev pab kev lom zem, chaw noj qab haus huv, nam. Nws muaj qhov zoo ntawm kev ua haujlwm yooj yim, tsis muaj suab nrov, kev ua tau zoo, kev teeb tsa zoo thiab kev txij nkawm. Nws muaj ntau yam zoo xws li kub tsis kam, corrosion tsis kam thiab tiv thaiv kev laus. Nws yog cov khoom tshiab tshiab ntawm cov dej kub.

Daim ntawv thov

1. Ntsug siv, xws li nyob rau hauv ib qho zoo;

2. Oblique siv, xws li nyob rau hauv ib tug kuv li nrog txoj kev nqes hav;

3. Kab rov tav siv, xws li hauv pas dej

QJ Submersible Hluav Taws Xob Twj Rau Zoo (Nqis Tej Twj) Ceev Faj

1. Cov twj tso kua mis zoo yuav tsum tau siv nyob rau hauv cov xuab zeb cov ntsiab lus ntawm tsawg dua 0.01% ntawm cov dej tso dej, lub peev xwm yuav tsum tau ua ntej ntawm cov dej ua ntej.

2. Tshiab lossis txhim kho cov twj tso kua mis kom zoo nkauj, yuav tsum kho lub plhaub twj tso kua mis thiab cov impeller incressance, tus impeller hauv kev ua haujlwm yuav tsis sib npaug nrog lub plhaub.

3. Cov kua dej zoo tob yuav tsum tau khiav ua ntej cov dej mus rau hauv tus ncej thiab coj lub plhaub rau kev ua ntej.

4. Ua ntej pib ntawm cov kua dej zoo sib sib zog nqus, cov khoom tshuaj ntsuam xyuas yuav tsum ua kom tau raws li cov kev cai hauv qab no:

1) puag hauv paus bolts raug nruj;

2) Axial clearance kom tau raws li qhov yuav tsum tau ua, kho cov kab xev liab tau raug ntsia;

3) Cov pob zeb ntim tau zawm thiab lubricated;

4) Lub cev muaj zog bearings tau siv lubricated;

5) Tig lub cev muaj zog rotor thiab nres tshuab los ntawm tes yog txhais tau thiab siv tau.

5. Cov twj tso kua mis zoo tob tsis tuaj yeem kaw nyob rau hauv rooj plaub ntawm dej. Twj tso rau ib lossis ob tus impellers yuav tsum tau raus hauv qab dej qis dua 1m. Kev ua haujlwm yuav tsum tau saib cov kev hloov pauv hauv qib dej hauv lub qhov dej.

6. Thaum lub sijhawm ua haujlwm, thaum koj pom qhov kev cai ua kom loj loj nyob ib ncig ntawm lub hauv paus, koj yuav tsum kos lub taub dej lossis lub cev muaj tub yees hnav; Thaum ntau hnav thiab to thiab to, yuav tsum hloov cov tshiab.

7. Tau nqus cov av nkos sib xyaw ua ntej tso kua mis, ua ntej nres lub twj tso kua mis, daim ntawv thov dej yaug.

8. Ua ntej nres lub twj tso kua mis, koj yuav tsum kaw lub qhov dej tso dej, txiav tawm lub zog, kaw lub thawv hloov. Thaum lub caij ntuj no yog neeg xiam oob khab, dej yuav tsum muab tso rau hauv lub twj tso kua mis.