Slurry Plut Goy

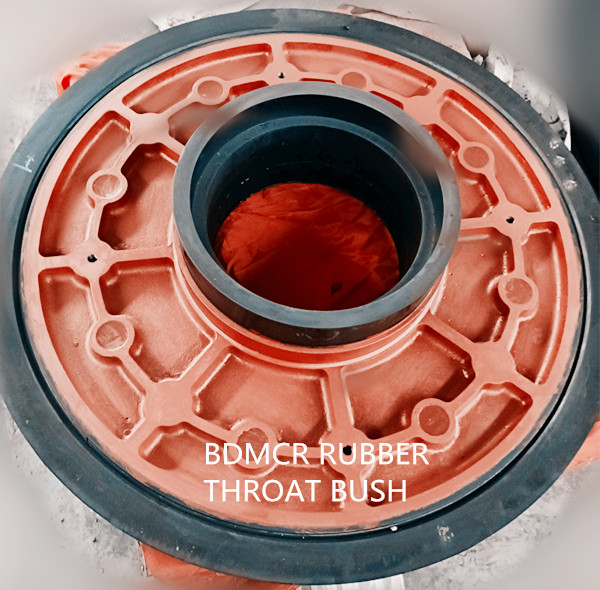

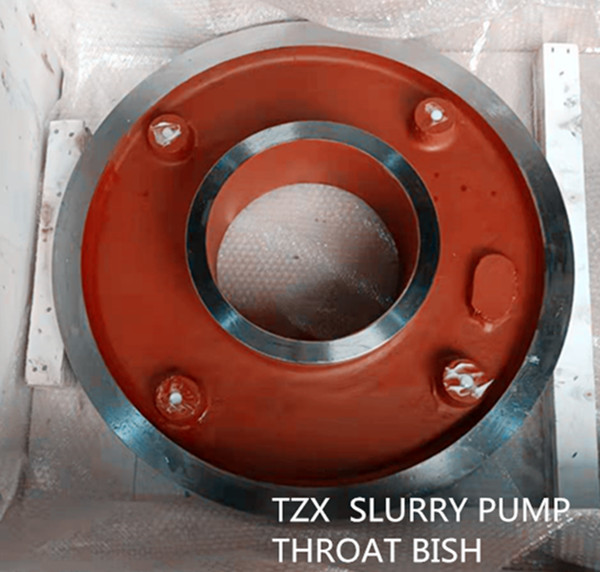

Akụkụ siri ike slurry akụkụ - akpịrị ehi

N'ihu anya na azụ Shrouds nwere mgbapụta pụọ na-ebelata ihe na-egbochi ya. Ndị na-eme ihe ike na usoro a hastastomer na-agbanwe agbanwe.

Plurry Prump Kush Consh Koodu: BDE4083, BDF6083, BDF8083.

Slurry pumples azụ

Polyurethane:

U01 bụ ihe na-eguzogide na-eme nke ọma na ngwa Elastom ebe 'tramp' bụ nsogbu. A mara nke a na akwa akwa na ike tensile nke U01. Agbanyeghị, nguzogide mbuze ya dị ala karịa nke roba eke.

Ihe omume ahaziri iche:

A na-ejikarị ihe ndị na-aga n'ihu na-aga n'ihu mgbe niile, EPDM, EPDMA, HD4MCIC, HD4MCIC, HD4MCIC, CD4MCIC, CD4MCU, aluminium na ihe ndị ọzọ na-emegide ndị ọzọ maka ngwa dị iche iche.

Ihe: Cr26, Cr20, Cr08, Br08, Br24, Br38, BS32, BS42, BS02, BS21, BS44 ...

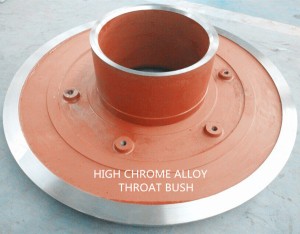

1. BDA05A na-eyi akwa mkpuchi na-eguzogide ọcha na-enye arụmọrụ dị mma n'okpuru ọnọdụ enasuve. Enwere ike iji alloy rụọ ọrụ nke ọma n'ọtụtụ ụdị slarry. A na-enye elu nguzogide nke alloy Bda05 ka ọ bụrụ ọnụnọ ụgbọ ala siri ike n'ime ihe owuwu ya. Alloy A05 kachasị mma na ngwa ebe m dị nro na-eguzogide nguzogide, yana nguzogide nguzogide na-eguzogide.

2. BDA07Marten-Sic ọcha na-eguzogide nguzogide.

3. BDA49Ọ dị mma maka ọrụ corrosion dị ala, ebe iyi ero bụ nsogbu. A na-ejikọ Alloy dị mma maka ngwa agha (FGD) na ngwa ndị ọzọ na-erughị 4. Siri ike 1.

Akụkụ mmiri na-agbagharị

• Mbelata- N'ihu na azụ shrouds nwere mgbapụta pụọ na-ebelata ihe na-egbochi mmerụ ahụ.

Ndị na-emepụta ọla na ha siri ike na-agbanwe agbanwe zuru oke. Tube na ntinye aka na-achoghi itinye ma obu nkpuru. A na-enwetakwa arụmọrụ dị elu na atụmatụ isi dị elu dịkwa.

• liners- A na - ejigide linen a na - emegharị, na - adịghị mma, na - adịghị mma, na casing maka mgbakwunye na ịdị mfe nke mmezi. Linen siri ike na-agbanwe agbanwe na nrụgide akpụ akpụ. Elastomer

Na-emechi mgbaaka azụ.

• akpịrị ọhịa -Iwe na-ebelata na ndozi ndozi site n'iji ya na-eme ka ihe dị mma iji kwe ka ọgbakọ na mwepụ dị mfe.

• kuru nzukọ -Nnukwu dayameta na obere ihe mmachi na-ebelata ntụpọ ma nye aka na ndụ dị ogologo. Naanị anọ site na bolts anọ iji jide ụdị katriki na etiti ahụ.

Slurry Pụrụ Akụkụ akụkụ

Slinry pumple mmiri mmiri na-etinye ọnụego na-agụnye nchekwa, mkpọchi, mkpuchi, mkpuchi, kpuchie ya, kpuchie ya lita, kpuchie ya. ..

1.Corcentrifugal nfuli elu na akụkụ ndị ọzọ nwere ike ijikọ ndụ ọhụụ a ma ama.

Nsuso nrụpụta 2.These bụ nke ihe owuwu dị arọ, nke e mepụtara maka ngwe na-aga n'ihu nke slurries na-aga n'ihu.

3. Ha na-egosipụta nhọrọ dị mma nke elastomer Elastomer Elastomer Elastomer Elastomer Elastomer Elastomer Elastomer na ndị na-eme ihe nkiri, nke a na-agbanwe agbanwe n'ime nzukọ na-ebute ụlọ.

4. linearsistrant metal liner na roba akwa dị

Condị 5.Seeal: gland akara, atụmatụ mmebi na akara nke arụ ọrụ

6.Can ka etinyere na usoro ọtụtụ

7oasy ka mmezi ya

Ngwongwo nke ihe roba:

Anyị nwere dị iche iche nke roba na elastomers, nke enwere ike iji ya na-adọpụta corrosive ma ọ bụ slirries acties. Ma ihe rọba adịghị mma maka slurries nke nwere ezigbo nkọ.Mgbe slurries nwere ezigbo irighiri ihe, ihe eji rọba na-arụ ọrụ dị mma nke na-eguzogide.

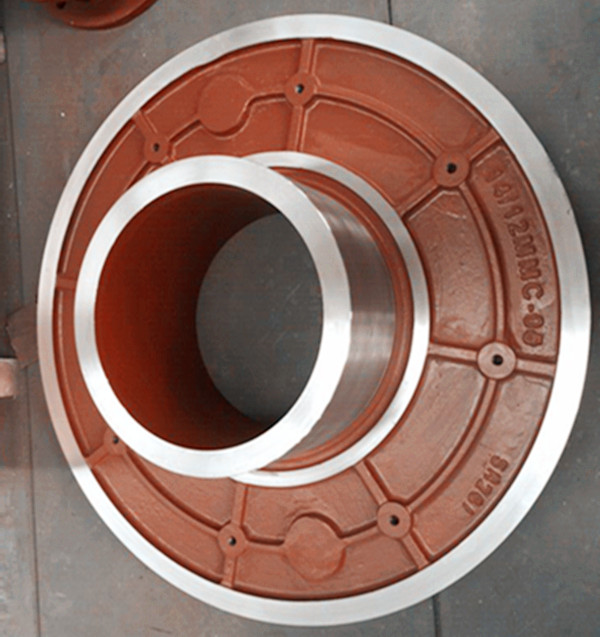

Ngwongwo nke nnukwu chì ígwè dị elu:

Anyị nwere ọtụtụ ụdị ígwè dị elu chrome, na ọdịnaya nke Chrome dị iche.

Ha nwere ike ịnye arụmọrụ dị mma n'okpuru ọnọdụ ehie ụzọ. Enwere ike iji alloy rụọ ọrụ nke ọma n'ọtụtụ ụdị slarry. A na-enye elu nguzogide nke alloy a na-enye site na ụgbọ ala siri ike n'ime micros. Solomefọdụ Chromelome pụrụ iche na-adabara iji tinye ebe nguzogide na-eguzogide, yana nguzogide nguzogide na-eguzogide.

Ọrụ OA

Dabere na ọtụtụ afọ nke ahụmịhe bara ụba na arụpụta mgbapụta na imewe, ozu na-eme ka oem na-ekwu okwu maka usoro mgbapụta na akụkụ dị iche iche. Enwere ike iji akụkụ ahụ dị iche iche mee ihe dị iche iche dị ka ihe ndị ahịa chọrọ, dị ka chọrọ: Alloy 20, Hastrelloy Alloy, A (6 1) na ndị ọzọ.

Companylọ ọrụ anyị na-arụpụta imewe, nhazi na mgbanwe nke akụkụ dị iche iche pụrụ iche. Dabere na ihe onye ọrụ ahụ, ụlọ ọrụ ahụ nwere ike imepụta ihe dị iche iche na ihe mejupụtara iji gboo mkpa nke ọnọdụ ọrụ dị iche iche. Ma ọ bụ dabere na mgbanwe nke teknụzụ akụrụngwa dị adị, tinyere hydraulic nke ụlọ ọrụ ụlọ ọrụ anyị, site na teknụzụ mmekọrịta kọmputa dị elu, iji nye ndị ọrụ na ngwọta zuru oke ma dị irè.

Ngwa:

A na-eji akụkụ ndị ahụ na-ejikarị ya na ngwa ọrụ dị ukwuu Nhazi ihe na-agbawa na Osimiri Smelse Smelel na Ọdọ mmiri na-eme ka ngwa ọrụ na-eme mkpọtụ na-awụpụ sọlfọ na-eme ka ịmịcha mmiri na-eme ka ọ bụrụ slings Pall Pall Suger Meather Posts FGD Frac Sand Confting City Suga ebe owuwu wdg.