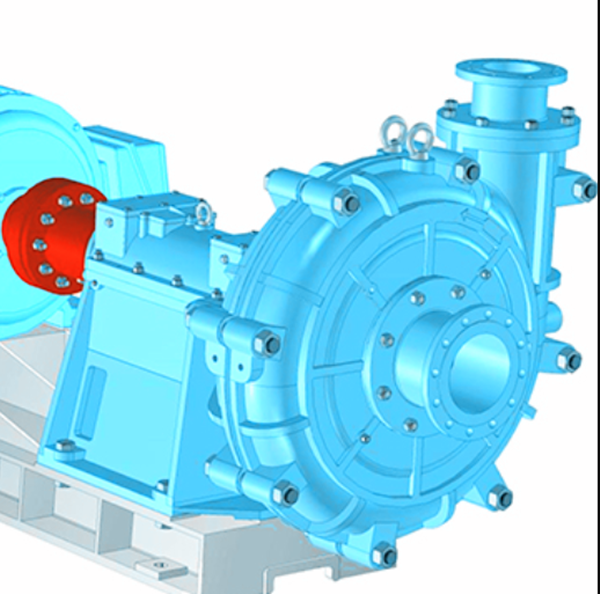

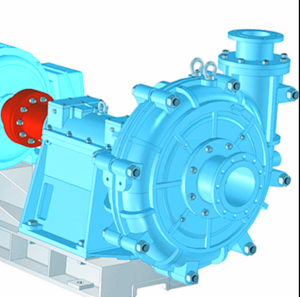

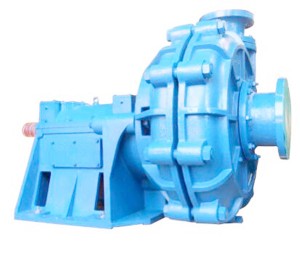

Pịnye ZGB (p) slurry

Mmeghe Mmeghe:

1. Ọrụ n 'arụmọrụ dị elu, cAD ọgbapụta, arụmọrụ dị elu na ọnụego mbịara ala234.5. Ndị metric na-eme ka mmanụ lubric, lubring na ndị na-ajụ oyi ma na-ajụ usoro na-agba mbọ ka a rụọ ọrụ n'okpuru okpomọkụ dị ala.

6. E nwere ike iji ihe dị mma nke akụkụ nke mgbochi na mgbochi mmiri, a ga-eji pumponway ash-corrosonion nke sweater, nnu na corrosion.

7. Enwere ike ịrụ ọrụ na ọtụtụ usoro na ọtụtụ usoro dị iche iche. Nrụgide kachasị ike na-arụ ọrụ bụ 3.6 MPA.

Usoro mgbapụta ahụ nwere uru owuwu ezi uche dị na ya, arụmọrụ dị elu, ọrụ ntụkwasị obi na mmezi dị mfe. Enwere ike iji ya mee ihe maka iji ngwakọta ahụ dị n'ime ya na corrosive na corring na ike eletrik, ọla m, ụlọ ọrụ na-ewuli elu maka iwepu uyi na sludge na ọdụ ụgbọ ala eletrik.

Ntụziaka:

1 Mgbapụta ahụ na-ebugharị na elekere elekere site na njedebe mbanye.

2 Ihe ndepụta ha na-emepụta bụ otu na otu. Maka akụkụ draịva nke usoro ZGB (p) slurry mgbapụta, eriri kwụ ọtọ na mmanụ na-eteta na mmiri oyi na-agbachi usoro na n'èzí. Ọ bụrụ na ọ dị mkpa, mmiri jụrụ oyi. Njikọ njikọta maka mmiri jụrụ oyi na nrụgide nke mmiri jụrụ oyi na tebụl 1.

3. A na-ejikọ ụdị akara ngosi abụọ dị iche iche na mbukota na akara nke eji eme ihe maka usoro ZGB (p) slurry.

4. A na-atụ aro nke ahụ eji arụ ọrụ dị elu na-atụ aro ya mgbe a na-arụ ọrụ mgbatị ahụ na usoro (akara abụọ na ọkwa dị elu), yana akara a na-ejikọ na ngwugwu.

Isi mmalite arụmọrụ:

|

Mogosi | Ọsọ n (r / min) | Ikike nke ikike q (l / s) | Isi H (m) | Max.eff. | Asash | Aro Ike (kw) | Sibelle Dia (mm) | Rọpụ arọ (n'arọ) | Outlet / inlet (mm) | |

| 65ZGB | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | 390 | 1850 | 65/80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| 80zGB | 980 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2 | 73.7-52.2 | 485 | 2500 | 80/100 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31.0-15.4 | 26.1-27.3 | 66.1-48.7 | 1.5-0.8 | 12.0-8.4 | |||||

| 100zGB | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100/152 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 980 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150ZGB | 980 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3.8-2 | 215.0-165.5 | 740 | 3450 | 150/200 | |

| 740 | 151.2-75.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 980 | 182.4-91.2 | 73.0-77.1.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.2-84.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| 200ZGB | 980 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 7.00 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 980 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| 250ZGB | 980 | 400.0-200.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | 7.00 | ||||

| 740 | 285.7-14.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300zGB | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300/350 | |

| 740 | 402.7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2.0 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-25.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |