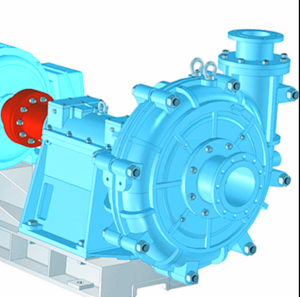

Tzsh dị elu chrome alloy slurry mgbapụta

Ngwa na atụmatụ:

A na-enwe contiled tzh usoro nfuli mmiri, kehoraifugal, centrifugal slurry, na-akụda mmụọ, na-ewu ụlọ na ngalaba ndị ọzọ na-emekwa. enwere ike itinye ya na usoro.

Ihe kpatara liner na iwenye ihe maka Tzsh na-anakwere nke igwe na-eguzogide na-eguzogide.

A na-achịkọta akara ahụ maka ụdị tzsh na-akara gland ma ọ bụ na-ere ya na ọkwa nke ogo iri anọ na ise site na ọnyà asatọ ọ bụla dabara na nrụnye na ngwa ọ bụla.

Okwu Mkpịrị na ụdị mgbapụta:

Na-ekwupụta na usoro arụmọrụ nke mgbapụta mgbapụta ndị ahọpụtara kwesịrị ịbụ dị ka ndị a:

Ntinye eserese:

Chaatị nhọrọ:

Isi Nrụpụta arụmọrụ:

| Ump nlereanya | Ekwe ka ọ bụrụ Max. Ike (kw) | Mezuo arụmọrụ mmiri | | |||||

| ike q | Isi h (m) | ọsọ n (r / min) | Max.eff. η% | Npsh (m) | DENELER DR (MM) | |||

| m3 / h | l / s | |||||||

| 25tzshpc | 30 | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 3300 |

| 50tzshpd | 60 | 68.4-137 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

| 75tzsh-pe | 120 | 126- 252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

| 100tzhshff | 560 | 324- 720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

| 150tzhys | 560 | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

MARA: Onu ogugu a na-atụ aro: 50% Q'≤q≤q o100% Q '(Q'' ekweghị na ike na isi ọrụ).

2.npsh: kwesịrị ekwesị iji tụọ akara q tụrụ aro na ọsọ kachasị elu.

Dee ozi gị ebe a ma zigara anyị ya