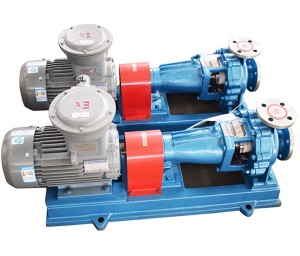

Pompa kimia stainless steel

Ih pompa kimia Katrangan Umum

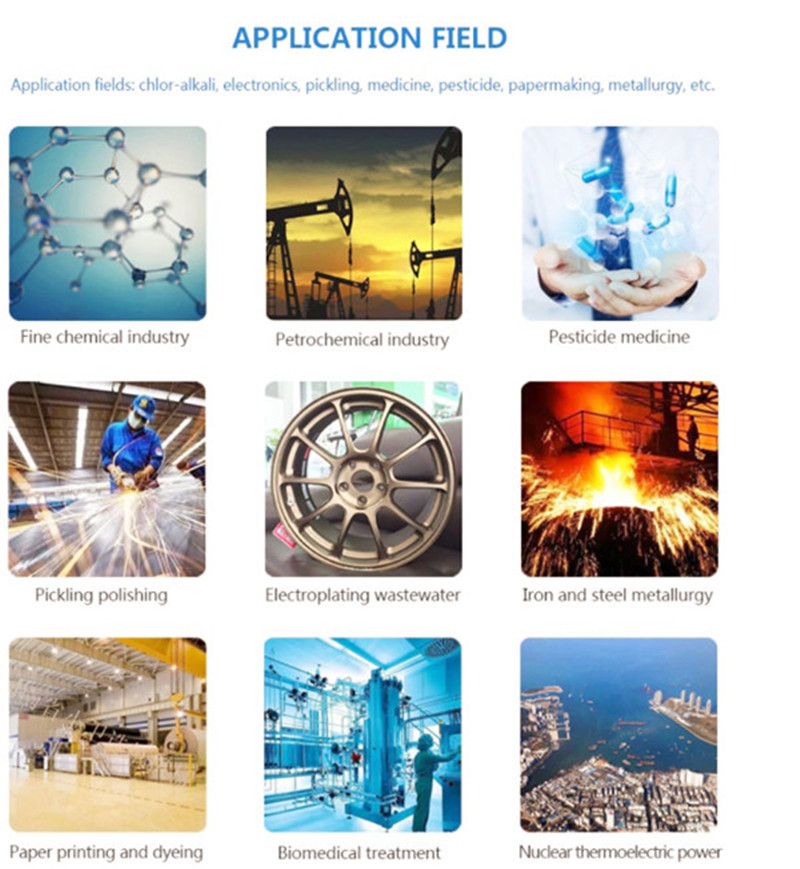

Pump Series IH minangka sedhot tunggal lan panggung tatu cantrifugal siji kanggo panggunaan industri kimia, singNganggo standar internasional, kanthi salaras karo standar ing iso28588, iso3069, iso3661. IkiProduct dikonfirmasi dening Departemen Industri Mesin Negara kanggo njupuk Corrosion Jenis FI - NganggepPompa centrifugal (ndhuwur 50 diameter) kanggo produk novel energi. Efisiensi yaiku 3 ~ 5% luwih dhuwur tinimbangF pompa pompa, volume residu rongga luwih unggul lan nyedhot fungsine, sing cocog kanggo ngaturCairan kanthi erosi, bisa ngetrapake departemen industri kimia, petroleum, industri metalgis,Nggawe kertas, panganan, industri farmasi lan industri kain senyawa lsp.

Spesifikasi: Kapasitas: 6.3 ~ 1150m3 / H, Kepala: 5 ~ 125m

Tekanan kerja: ≤2.5MPA, yaiku tekanan intake + head≤2.5MPA, materi casting: ≤1.6 MPA

Suhu sing kerja: -20 ℃ ~ 80 ℃

Makna model: uh80-50-200a

Ih-seri pompa industri centrifugal internasional internasional

Diameteripun 80-inlet 80mm

50-outlet Diameter 50mm

Diameteripun 200-Nominal Impeller 200mm

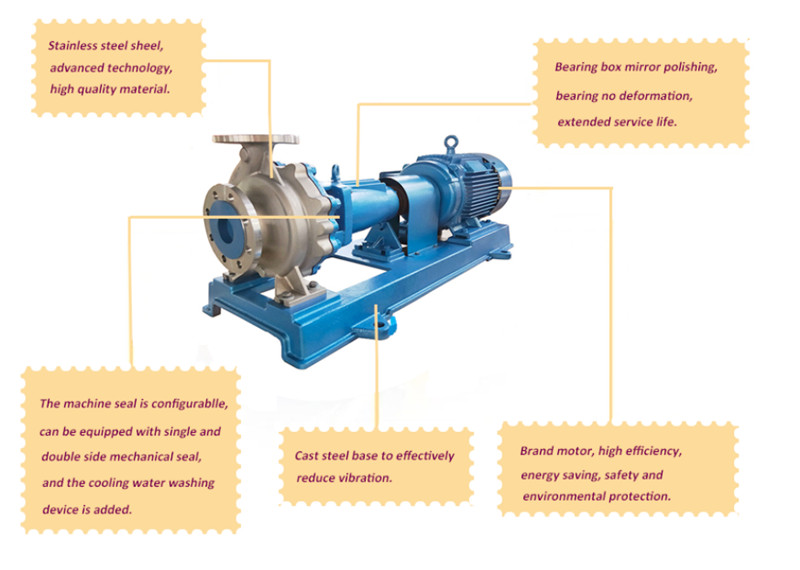

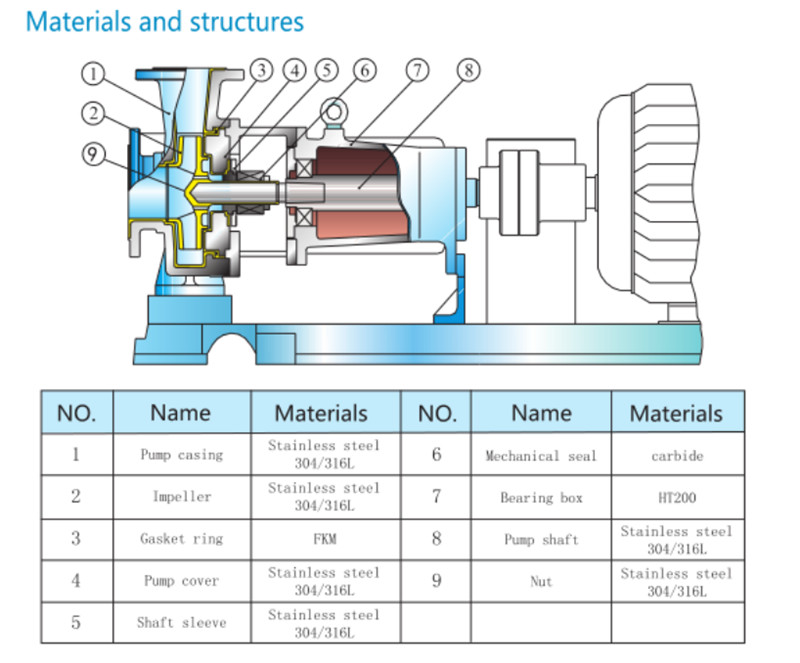

Ih pompa kimiaWulu saka struktur

Pompa kasebut kalebu pump casing, impeller, sealing ring, pompa lan omah lan bearing omah ing lawang mburi, kanggo nggampangake pangopènan tanpa dibentuk. Akeh penak ing aplikasi.

Casing pompa dirancang karo sikil ing ngisor iki, lan disaranake dipanggonke ing ndhuwur, nyedhot ing axial.

Ukuran pompa flange diakoni GB9113.3-88 (1.6Mpa), padha karo HG20595-97 (1.6Mpa).

Part Rotor didhukung dening gulung-gulungan, bantalan nggunakake minyak mesin N33 kanggo lubrication, yen sampeyan pengin nggunakake pelumas kanggo lubrication, tulungake cathetan kasebut.

Kacang impeller nganggo spacer baja kanggo nyegah ngeculke, sing bisa nyegah kacang impeller amarga geter ing operasi lan rotasi mbalikke.

Meter minyak nggunakake jinis makam otomatis, supaya bisa njamin pelumas sajrone operasi, saengga mundhakaken umur pompa.

Ndeleng saka mburi driver, arah rotasi pompa ing jam kanthi jam.

Bahan bagean sing dikirim karo Cairan digawe dening 1cr18ni9,1cr18ni9ti, 304,304l, 316,316L, 964, Alloy alloy lan liya-liyane, kita uga bisa nganggo bahan resistensi karat liyane miturut pangguna syarat.

Ih pompa kimiaShaft Sealing

Segara shaft nganggo sealing seating, stuffing mechanical sealing, utawa sealing mekanik pindho. Yen ngono, tekanan nyedhot pompa luwih gedhe, mula sampeyan milih milih Seimbangan Mekanikan Segilan.

Penelasi pemutuhan digunakake ing kasus yen syarat kanggo situs ing clearance ora ketat lan bocor sethithik diidini. Utawa, yen cairan dikirim kanthi gampang dicritakake utawa ana gandum, mula uga menehi saran kanggo nggunakake Setuver Seualing.

Penafe mekanik ditondoi kanthi fungsi sing bisa dipercaya, bocor kurang lan wektu suwe. Dibagi santai mekanik siji lan santai mekanik kaping pindho. Ing endi sealing mekanik kaping pindho cocog kanggo ngetrapake acara sing dhuwur, amarga gampang dibakar, gampang bledosan, lan kanthi cepet agen, kanthi gampang dicelupake lan nganggo agen kanthi gampang.

Ana piranti siram kanthi otomatis ing jero sebutan mekanik siji. Dene kebutuhan mekanik kaping pindho sing kudu nyambung karo njaba kanggo cairan siram, sing macem-macem gelar amarga bedane cair, suhu lan tekanan. Cairan siram njupuk banyu utawa pompa medium sing jelas. Yen suhu suhu agen kasebut dhuwur utawa ana gandum, mula kudu ditindakakeKelangan terus menyang agen pisanan, sawise nyaring banjur mlebu menyang rongga sealing.

Tekanan cuci cairan kudu 0,05 ~ 0.1MPA luwih dhuwur tinimbang tekanan ing ngarepe santai. Sadurunge miwiti pompa, kudu mbukak sistem cuci lan pendinginan ing wiwitan, lan ora ngethok sistem kasebut sadurunge mandheg operasi.

Tekanan flush flush: meksa pump push tekanan + sirah × 45%

(Maksimal ora ndhuwur 0,8MPA kanggo sealing mechanical sing ora seimbang)

冲洗液温度 Suhu Cantik Flush: <40 ℃

冲洗液流量按下表 kapasitas cairan siram:

| 机械密封规格 (mm) Spesifikasi segel mekanik | <45 | 45 ~ 60 | 60 ~ 80 |

| 冲洗液流量 (升 / 分) Kapasitas Cairan Flush (l / m) | 4 | 5 | 6 |

Tabel kinerja pompa kimia:

| N | Model | REV = 2900R / min medium kapadhetan = 1000kg / m³ | |||||||

| Aliran | Pompa sirah | η | Inlet | Outlet | NPSH | Kekuwatan | Bobot | ||

| (mɪ / h) | (m) | (%) | (mm) | (mm) | (m) | (kw) | (kg) | ||

| 1 | Eh25-20-125 | 2 | 20 | 27 | φ25 | φ20 | 2 | 0,75 | 55 |

| 2 | Ih25-20-160 | 2 | 32 | 25 | φ25 | φ20 | 2 | 1.1 | 60 |

| 3 | Eh25-20-200 | 2 | 50 | 22 | φ25 | φ20 | 2 | 2.2 | 85 |

| 4 | Ih32-20-125 | 3.6 | 20 | 32 | φ32 | φ20 | 2 | 1.1 | 60 |

| 5 | Ih 32-20-160 | 3.6 | 32 | 30 | φ32 | φ20 | 2 | 1.5 | 70 |

| 6 | Ih32-20-200 | 3.6 | 50 | 27 | φ32 | φ20 | 2.5 | 3 | 100 |

| 7 | Ih40-25-125 | 6.3 | 20 | 39 | φ40 | φ25 | 2.5 | 1.5 | 65 |

| 8 | Ih40-25-160 | 6.3 | 32 | 36 | φ40 | φ25 | 2.5 | 2.2 | 75 |

| 9 | Ih40-25-200 | 6.3 | 50 | 32 | φ40 | φ25 | 2.5 | 5.5 | 120 |

| 10 | Ih40-25-250 | 6.3 | 80 | 28 | φ40 | φ25 | 2.5 | 7,5 | 165 |

| 11 | IH50-32-125 | 12.5 | 20 | 50 | φ50 | φ32 | 2.5 | 2.2 | 70 |

| 12 | Ih50-32-160 | 12.5 | 32 | 48 | φ50 | φ32 | 2.5 | 4 | 120 |

| 13 | IH50-32-200 | 12.5 | 50 | 45 | φ50 | φ32 | 2.5 | 7,5 | 155 |

| 14 | Ih50-32-250 | 12.5 | 80 | 39 | φ50 | φ32 | 2.5 | 11 | 220 |

| 15 | Ih65-50-112 | 25 | 20 | 62 | φ65 | φ50 | 2.5 | 3 | 85 |

| 16 | Ih65-50-160 | 25 | 32 | 58 | φ65 | φ50 | 2.5 | 5.5 | 135 |

| 17 | Ih65-40-200 | 25 | 50 | 52 | φ65 | φ40 | 2.5 | 11 | 190 |

| 18 | Ih65-40-250 | 25 | 80 | 49 | φ65 | φ40 | 2.5 | 15 | 250 |

| 19 | Ih80-65-125 | 50 | 20 | 66 | φ80 | φ65 | 3 | 5.5 | 105 |

| 20 | Ih80-65-160 | 50 | 32 | 64 | φ80 | φ65 | 3 | 11 | 170 |

| 21 | Ih80-50-200 | 50 | 50 | 60 | φ80 | φ50 | 3 | 15 | 210 |

| 22 | Ih80-50-250 | 50 | 80 | 56 | φ80 | φ50 | 3,5 | 30 | 360 |

| 23 | Ih100-80-125 | 100 | 20 | 73 | φ100 | φ80 | 3,5 | 11 | 175 |

| 24 | Ih100-80-160 | 100 | 32 | 69 | φ100 | φ80 | 3,5 | 15 | 215 |

| 25 | Ih100-65-200 | 100 | 50 | 65 | φ100 | φ65 | 3,5 | 30 | 350 |

| 26 | Ih100-65-250 | 100 | 80 | 62 | φ100 | φ65 | 4 | 45 | 480 |

| 27 | Ih125-80-160 | 160 | 32 | 70 | φ125 | φ80 | 4 | 30 | 410 |

| 28 | Ih125-100-200 | 200 | 50 | 69 | φ125 | φ100 | 4.5 | 55 | 590 |

| N | Model | REV = 1450R / min densitas medium = 1000kg / m ³ | |||||||

| Aliran | Pompa sirah | η | Inlet | Outlet | NPSH | Kekuwatan | Bobot | ||

| (mɪ / h) | (m) | (%) | (mm) | (mm) | (m) | (kw) | (kg) | ||

| 1 | Eh25-20-125 | 1 | 5 | 24 | φ25 | φ20 | 2 | 0.37 | 51 |

| 2 | Ih25-20-160 | 1 | 8 | 22 | φ25 | φ20 | 2 | 0.37 | 56 |

| 3 | Eh25-20-200 | 1 | 12.5 | 20 | φ25 | φ20 | 2 | 0,55 | 68 |

| 4 | Ih32-20-125 | 1.8 | 5 | 28 | φ32 | φ20 | 2 | 0.37 | 55 |

| 5 | Ih32-20-160 | 1.8 | 8 | 27 | φ32 | φ20 | 2 | 0,55 | 60 |

| 6 | Ih32-20-200 | 1.8 | 12.5 | 23 | φ32 | φ20 | 2.5 | 0,55 | 80 |

| 7 | Ih40-25-125 | 3.2 | 5 | 35 | φ40 | φ25 | 2.5 | 0.37 | 58 |

| 8 | Ih40-25-160 | 3.2 | 8 | 33 | φ40 | φ25 | 2.5 | 0,55 | 65 |

| 9 | Ih40-25-200 | 3.2 | 12.5 | 30 | φ40 | φ25 | 2.5 | 1.1 | 88 |

| 10 | Ih40-25-250 | 3.2 | 20 | 25 | φ40 | φ25 | 2.5 | 1.1 | 115 |

| 11 | IH50-32-125 | 6.3 | 5 | 45 | φ50 | φ32 | 2.5 | 0,55 | 60 |

| 12 | Ih50-32-160 | 6.3 | 8 | 42 | φ50 | φ32 | 2.5 | 0,55 | 70 |

| 13 | IH50-32-200 | 6.3 | 12.5 | 38 | φ50 | φ32 | 2.5 | 1.1 | 90 |

| 14 | Ih50-32-250 | 6.3 | 20 | 34 | φ50 | φ32 | 2.5 | 1.5 | 140 |

| 15 | Ih65-50-112 | 12.5 | 5 | 57 | φ65 | φ50 | 2.5 | 0,55 | 64 |

| 16 | Ih65-50-160 | 12.5 | 8 | 53 | φ65 | φ50 | 2.5 | 1.1 | 78 |

| 17 | Ih65-40-200 | 12.5 | 12.5 | 46 | φ65 | φ40 | 2.5 | 1.5 | 100 |

| 18 | Ih65-40-250 | 12.5 | 20 | 43 | φ65 | φ40 | 2.5 | 2.2 | 165 |

| 19 | Ih80-65-125 | 25 | 5 | 62 | φ80 | φ65 | 2.8 | 1.1 | 85 |

| 20 | Ih80-65-160 | 25 | 8 | 59 | φ80 | φ65 | 2.8 | 1.5 | 97 |

| 21 | Ih80-50-200 | 25 | 12.5 | 55 | φ80 | φ50 | 2.8 | 2.2 | 115 |

| 22 | Ih80-50-250 | 25 | 20 | 53 | φ80 | φ50 | 2.8 | 4 | 185 |

| 23 | Ih100-80-125 | 50 | 5 | 65 | φ100 | φ80 | 3 | 1.5 | 110 |

| 24 | Ih100-80-160 | 50 | 8 | 61 | φ100 | φ80 | 3 | 2.2 | 140 |

| 25 | Ih100-65-200 | 50 | 12.5 | 57 | φ100 | φ65 | 3 | 4 | 260 |

| 26 | Ih100-65-250 | 50 | 20 | 54 | φ100 | φ65 | 3 | 7,5 | 330 |

| 27 | Ih125-80-160 | 80 | 8 | 68 | φ125 | φ80 | 3.2 | 4 | 280 |

| 28 | Ih125-100-200 | 100 | 12.5 | 65 | φ125 | φ100 | 3,5 | 7,5 | 330 |

| 29 | Ih125-100-250 | 100 | 20 | 70 | φ125 | φ100 | 3,5 | 11 | 360 |

| 30 | Ih125-100-315 | 100 | 32 | 67 | φ125 | φ100 | 3,5 | 18.5 | 430 |

| 31 | Ih125-100-400 | 100 | 50 | 64 | Ф125 | Ф100 | 3.8 | 37 | 520 |

| 32 | IH150-1OOXT-250 | 200 | 20 | 74 | φ150 | φ125 | 3.8 | 22 | 460 |

| 33 | Ih150-1O60-315 | 200 | 32 | 69 | φ150 | φ125 | 4 | 45 | 580 |

| 34 | Ih150-125-400 | 200 | 50 | 66 | φ150 | φ125 | 4 | 75 | 760 |

| 35 | Ih200-150-50 | 400 | 20 | 76 | φ200 | φ150 | 4.2 | 55 | 590 |

| 36 | Ih200-150-3 | 400 | 32 | 73 | φ200 | φ150 | 4.5 | 75 | 820 |

| 37 | Ih200-1500000 | 400 | 50 | 70 | φ200 | φ150 | 4.5 | 110 | 1080 |

| 38 | IH250-200-250 | 650 | 20 | 78 | Ф200 | Ф150 | 4.5 | 75 | 940 |

| 39 | IH250-200-315 | 650 | 32 | 75 | Ф200 | Ф150 | 4.8 | 110 | 1160 |

| 40 | IH250-400000000 | 650 | 50 | 72 | Ф200 | Ф150 | 5 | 132 | 1380 |

| 41 | Ih300-250-250 | 1000 | 20 | 79 | Ф300 | Ф250 | 5.5 | 110 | 1320 |

| 42 | Ih300-2-315 | 1000 | 32 | 77 | Ф300 | Ф250 | 6 | 160 | 1750 |

| 43 | Ih300-250-450-450 | 1000 | 50 | 74 | Ф300 | Ф250 | 6 | 250 | 2380 |