Ketik zgb (p) pompa slurry

Pambuka fungsi:

1. Kinerja hidraulik majeng, desain modern CAD, efisiensi dhuwur lan tingkat abrasion ngisor2 .. Wangsulan, ora clogging lan kinerja NPSH sing apik.3 .. segel pecra digabung karo segel segel lan segel mekanik kudu diadopsi kanggo njamin slurry saka bocor.4. Desain linuwih mesthekake MTBF dawa (tegese wektu antarane acara)5. Ngalahake metrik kanthi lubrication minyak, sistem pelumas lan pendinginan sing cukup njamin banter bisa dilakokno ing suhu sing luwih murah.

6. Bahan-bahan bagean teles duwe kinerja sing apik lan anti-karat, pompa bisa digunakake kanggo banyu laut banyu banyu banyu laut, uyah lan kedut, lan korosi elektrokimia.

7. Pompa bisa dilakokno ing seri kanthi macem-macem tahapan tekanan. Tekanan kerja maksimal sing diidini yaiku 3.6 MPA.

Seri pompa duwe kauntungan saka konstruksi sing cukup, efisiensi dhuwur, operasi sing dipercaya lan gampang pangopènan. Bisa digunakake kanthi akeh kanggo nangani campuran sing ngemot padatan abrasive lan corrosive ing kekuwatan listrik, minallurgy, tambang, batu bara, bahan konstruksi lan bahan kimia, konstruksi ing awu lan sludge ing stasiun listrik listrik.

Fitur Pump:

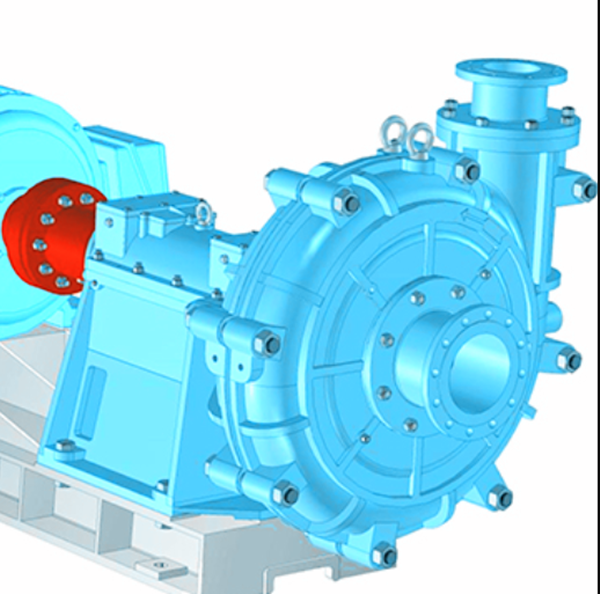

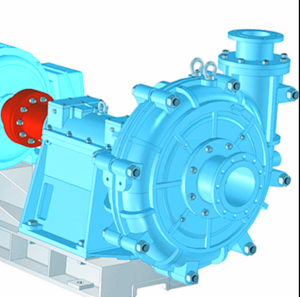

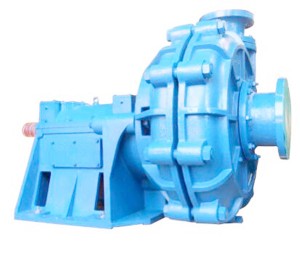

1 .. SERI ZGB (P) pompa slurry yaiku horisontal, tunggal, sundel, cantilever, casing pindho, casrifugal, pompa slurry. Pump muter ing Clockwise sing dideleng saka mburi drive.

2 .. Bagean teles zgb lan pompa zgbp ing diameter outlet sing padha bisa uga ditukar. Dimensi instalasi kanthi garisane siji lan padha. Kanggo bagean drive seri zgb (P), pigura pamisah horisontal kanthi lubrication minyak lan rong set sistem pendinginan banyu ing njero lan njaba diadopsi. Yen perlu, banyu pendinginan bisa diwenehake. Sendhi sing disiapake kanggo banyu pendinginan lan tekanan banyu pendinginan bisa katon ing tabel 1.

3. Loro jinis santai segel-pakar-pakar-gabungan digabung karo segel mekanik sing wis digunakake kanggo seri zgb (p).

4. Sejilan mekanik sing diwenehake kanthi banyu sealing tekanan tinggi disaranake nalika pompa sing dilakokno ing seri (rong tahap lan ndhuwur rong tahapan sing digabungake ing pompa tunggal.

Tabel kinerja pompa:

|

Model | Kacepetan n (r / min) | Kapasitas Q (L / S) | Sirah H (m) | Max.eff. | NPSH | Gagang Kekuwatan (kw) | Impeller Dia (mm) | Pompa bobote (kg) | Outlet / Inlet (MM) | |

| 65zg | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4,5-5.0 | 28.8-19.9 | 390 | 1850 | 65/80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| 80zgb | 980 | 56,7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | 80/100 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31.0-15.4 | 26.1-27.3 | 66.1-48.7 | 1.5-0.8 | 12.0-8.4 | |||||

| 100ZGB | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100/152 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 980 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150zg | 980 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3.8-2.7 | 215.0-165.5 | 740 | 3450 | 150/200 | |

| 740 | 151.2-75.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 980 | 182.4-91.2 | 73.0-77.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.2-84.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| 200zg | 980 | 300,0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 980 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38,0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| 250zg | 980 | 400.0-200.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | 700 | ||||

| 740 | 285.7-142.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300zgb | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300/350 | |

| 740 | 402,7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2.0 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-45.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |