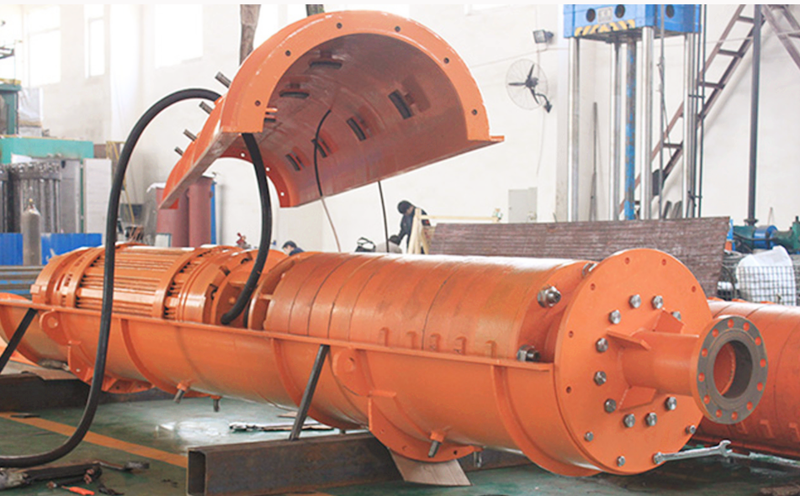

Mining Submersible Motor Pump

Product interview:

These series pumps are made in accordance with technique introduced from Ritz Co. of F.R.G.These products have advanced construction, high efficiency unit, superior material, long service life, reliable operation and small noise, etc.The series products and submersible motors are integrated into one unit submerged in water to work.

Features:

① High safety and reliability: The prerequisite for the design and use of the pump and the supporting submersible motor is to work in the water. If there is a water penetration accident in the mine, the drainage capacity of the submersible pump is not affected in any way, which will win precious time for the personnel to raise the well safely, and the mine can be used normally during normal mining and flooding. It is especially suitable for mines with large water influx, complicated geological and hydrological conditions, flood threat or water inrush danger. The comprehensive equipment investment is small and the cost performance is high.

② High efficiency and energy saving, high degree of automation: the ground is powered separately, and multifunctional detection and control can be realized on the ground. The electric pump is equipped with multiple monitoring protections, which is easy to implement intelligent monitoring, remote control, and networked management. It can be combined with the actual water inflow of the mine and the running time of the electric pump for remote control and rotation operation to realize "unattended pumping station". At the same time, the power supply can be reasonably arranged according to the principle of "avoiding peaks and filling valleys" to achieve energy saving and consumption reduction to the greatest extent.

③ The water pump unit can be used in vertical, inclined and horizontal: respond to various complex mine conditions, maximize drainage capacity, avoid drainage dead angles, and combine with relay drainage pumps or buoy devices to complete the entire process of emergency drainage and water chasing , Applicable to all kinds of underground mines and open-pit mines.

④ Simple and convenient installation and operation: The submersible electric pump system has low requirements for underground installation environmental conditions, and the amount of roadway infrastructure construction is small. It can be operated vertically, horizontally or obliquely. It can be placed in a place suitable for drainage according to local conditions and has a wide range of applications. At the same time, the motor is submerged in water to run, the heat generated is taken away by the water, the noise is small, and there is no temperature rise, it solves the motor heat dissipation and ventilation problems of the central pump room when multiple horizontal pumps are running, and improve the operating environment of the pump room.

Installation method of submersible electric pump:

Since our company discovered that there are more changes in the water quality and installation methods of domestic mines, we have improved the horizontal and inclined installation of submersible electric pumps and put them into market use. The bearing bush between each stage of the water pump can be used as a support point for horizontal and inclined use. Relatively speaking, the improvement of the pump is small. It mainly solves the problem of the support strength of the pump bearing bush and improves the strength and wear resistance of the support point; while for the motor, Comprehensive consideration: the rigidity and strength of the shaft, the balance of the horizontal operation of the rotor, the strength and rigidity of the upper and lower bearings, the influence and change of the clearance after horizontal use, and the motor sealing and cooling have been recalculated and tested. From the initial oblique 30 to horizontal installation, a comprehensive experiment of various indicators was carried out. Finally, the design requirements were fully met, and a pump can be installed horizontally, obliquely, and horizontally.

Since the product has been used for vertical and horizontal purposes, it has reduced the current installation conditions of customers, provided customers with more choices, and expanded the applicable conditions of submersible electric pumps. Other locations for easy drainage have been widely used in the market.

① Vertical installation

The vertical installation method of the submersible electric pump unit is suitable for vertical wells to set up wellbore sump drainage and surface drainage. The diving wire is suspended from the wellbore sump. The advantage is that the receiving method is reasonable, the operation is stable, the water storage area is small, and the drainage efficiency is high. The disadvantage is that the vertical water tank has a large depth, and at the same time, it does not need to reserve enough lifting space, which has higher requirements for supporting a large amount of load.

② Horizontal and oblique installation methods

The horizontal electric pump unit has the advantages of convenient installation, easy lifting, and small construction volume of the sump. Combined with the horizontal pump truck and rollers, it can quickly perform drainage work.

③ It can be installed and used in underground main drainage, track installation emergency drainage, and non-track inclined well to restore productive drainage

Main drainage: Submersible electric pump is used as the main drainage equipment. It covers a small area and has a small roadway construction. Combined with the pump truck and the unit, it is installed with clamp rollers or foundation support. Installed in the underground connection roadway sump pump position, the provincial special gland room, the water distribution lane connecting the pump room and the sump is equipped with a water distribution valve.

Emergency drainage for track installation: the electric pump unit goes down the track to the bottom of the well, and completes the drainage operation in one time. The pump adjusts its position quickly to shorten the drainage time. At the same time, there is little requirement for lifting equipment.

Trackless rescue and recovery of production drainage:

For waste mine tracks and other mines that do not have large submersible pumps for direct installation, a joint drainage system composed of submersible pumps, suction covers, pressure hoses, and relay pumps is used. The relay pump is combined with the main drainage pump, and the relay pump is installed in At the bottom of the main drain pump, the steel pipe gushes through the steel pipe to feed water to the main drain pump for draining operations. The relay pump is easy to maintain and move, and to avoid the bottom of the well silt and debris. Take the drainage method of drainage, repair, and laying of tracks until the drainage reaches the bottom of the well.

Application:

The Series products are mainly used for permanent discharge in mine, drying and earth surface and lifting water in factory and mine enterprises and deep wells of city and countryside.In recent years, the series pumps are used for rushing to save from flood especially in mining industries showing the extreme superiority.