Tip zgb (p) pompa tad-demel likwidu

Introduzzjoni tal-Funzjoni :

1. Prestazzjoni idrawlika avvanzata, disinn modern CAD, effiċjenza għolja u rata ta 'brix aktar baxxa2. Passaġġ wiesa ', mhux imblukkat u prestazzjoni tajba ta' NPSH.34. Id-disinn tal-affidabbiltà jiżgura MTBF twil (ħin medju bejn l-avvenimenti)15

6. Il-materjali ta 'partijiet imxarrbin kellhom il-prestazzjoni tajba ta' anti-ilbies u anti-korrużjoni, il-pompa tista 'tintuża għall-irmied tal-ilma baħar li jitneħħa biex ma jħallixha mill-korrużjoni ta' sweater, melħ u ċpar, u korrużjoni elettrokimika.

7. Il-pompa tista 'titħaddem f'serje b'ħafna stadji fi pressjoni permissibbli. Il-pressjoni massima permissibbli tax-xogħol hija 3.6 MPa.

Is-serje ta 'pompa għandha l-vantaġġ ta' kostruzzjoni raġonevoli, effiċjenza għolja, tħaddim affidabbli u manutenzjoni faċli. Jista 'jintuża ħafna għall-immaniġġjar tat-taħlita li tinsab ta' solidi li joborxu u korrużivi fl-enerġija elettrika, metallurġija, minjieri, faħam, materjal ta 'kostruzzjoni u dipartimenti tal-industrija kimika speċjali għat-tneħħija ta' l-irmied u l-ħama fl-enerġija elettrika.

Karatteristiċi tal-Pompa:

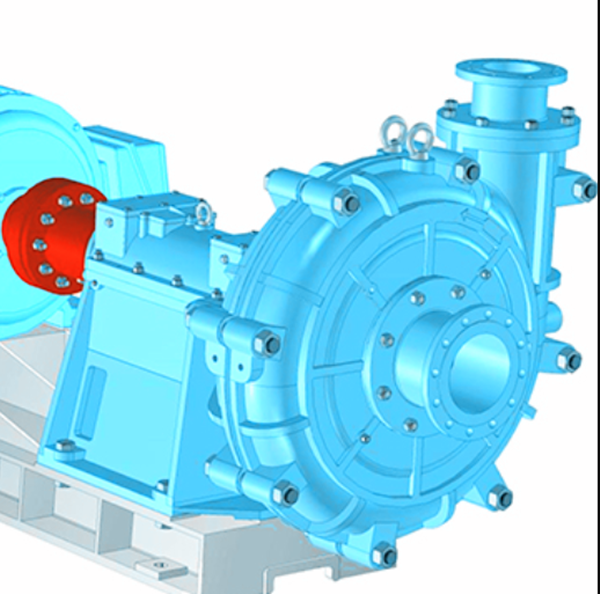

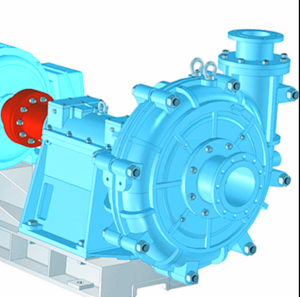

1. Il-pompa tad-demel likwidu ZGB (P) hija ta 'pompa orizzontali, ta' stadju wieħed, ta 'soluzzjoni waħda, cantilever, double-casing, pompa tad-demel likwidu ċentrifugali. Il-pompa ddur fil-lemin meqjusa mit-tarf tas-sewqan.

2. Il-partijiet imxarrbin tal-pompa ZGB u ZGBP fl-istess dijametru tal-ħruġ jistgħu jkunu interkambjabbli. Id-dimensjonijiet tal-installazzjoni tal-kontorn tagħhom huma wieħed u l-istess. Għall-parti tas-sewqan tal-pompa tad-demel likwidu ZGB (P), il-qafas maqsum orizzontali bil-lubrikazzjoni taż-żejt u żewġ settijiet ta 'sistemi ta' tkessiħ ta 'l-ilma ġewwa u barra ġie adottat. Jekk meħtieġ, ilma li jkessaħ jista 'jiġi fornut. Il-ġonta ppreparata għall-ilma li jkessaħ u l-pressjoni ta 'l-ilma li jkessaħ tista' tidher fit-Tabella 1.

3

4

Tabella tal-Prestazzjoni tal-Pompa:

|

Mudell | Veloċità N (r / min) | Kapaċità Q (L / S) | Ras H (m) | Max.eff. | Npsh | Xaft Qawwa (KW) | Impeller Dia (mm) | PUMP PIŻ (kg) | Outlet / Inlet (mm) | |

| 65ZGB | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | 390 | 1850 | 65/80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| 80ZGB | 980 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | 80/100 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31.0-15.4 | 26.1-27.3 | 66.1-48.7 | 1.5-0.8 | 12.0-8.4 | |||||

| 100ZGB | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100/152 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 980 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150ZGB | 980 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3.8-2.7 | 215.0-165.5 | 740 | 3450 | 150/200 | |

| 740 | 151.2-75.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 980 | 182.4-91.2 | 73.0-77.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.2-84.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| 200ZGB | 980 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 980 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| 250ZGB | 980 | 400.0-200.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | 700 | ||||

| 740 | 285.7-142.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300ZGB | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300/350 | |

| 740 | 402.7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2.0 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-45.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |