Knowledge

-

Slurry commissioning procedure time

slurry pump unit adjusted after installation, you can test run, conditional user, you should first use Shimizu trial run, run normal after delivery slurry, test steps are as follows: 1, open the seal water and cooling water, the pressure is adjusted...Read more -

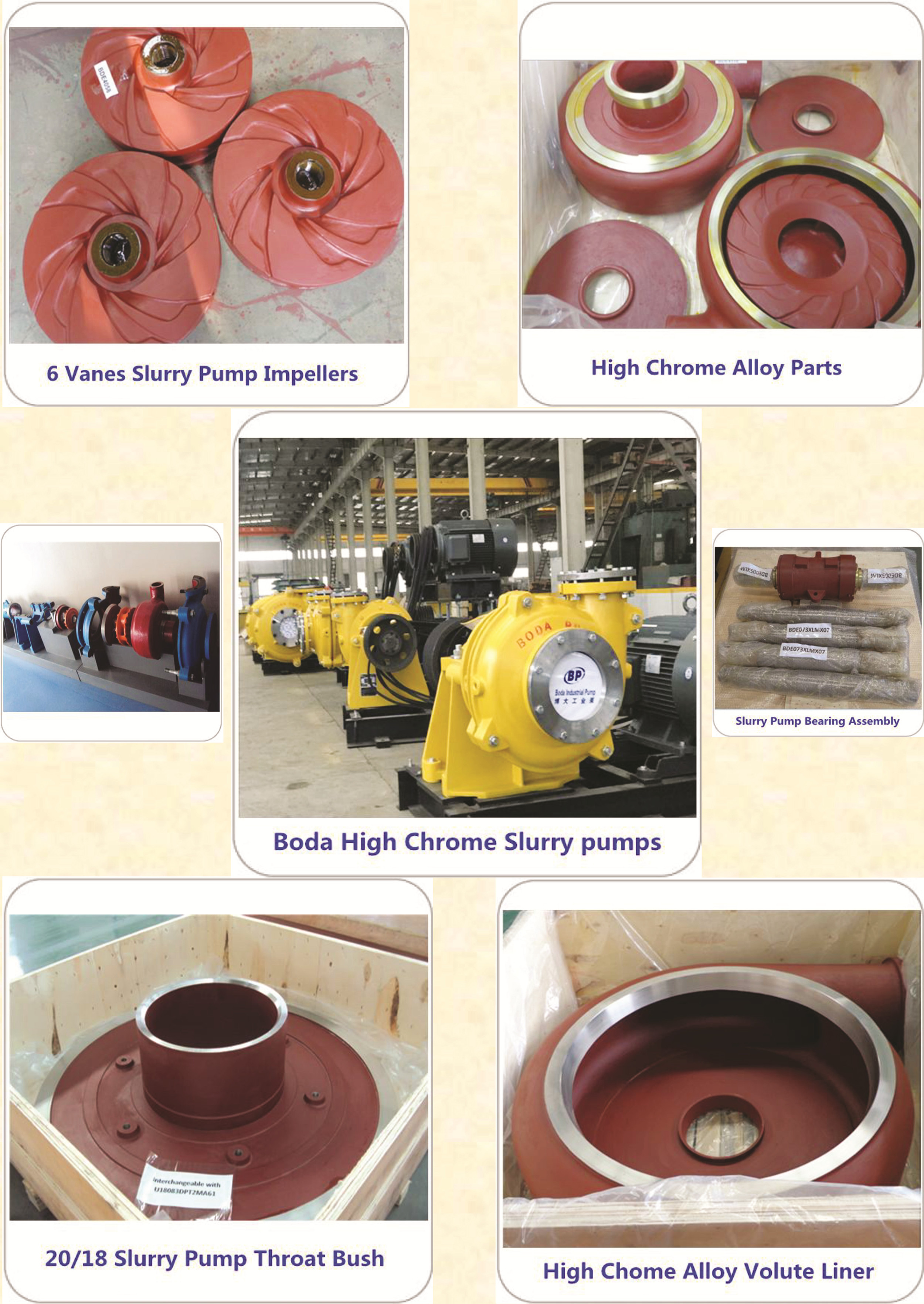

Horizontal Centrifugal Slurry Pumps

I: Slurry Pumps Material used:1)High chrome alloy: A05, A07, A49, etc.2)Natural rubber: R08, R26, R33, R55, etc.3)Other materials can be supplied as requirements . II: Slurry Pumps Applications:Alumina,Copper mining,Iron ore,Gas oil,Coal ,Electric industry,Phosphate,Bauxite,Gold,Potash, Wolf...Read more -

Gravel Dredge Pumps Made in China

In harsh conditions with sand, sludge, rocks, slurry, normal dredge pumps clog, wear and fail more often. This leads to downtime for maintenance, hurting your bottom line. Not the case with BODA Gravel Dredge Pumps, since we have the tolerance to pump particle size up to 9 inches ! &...Read more -

UHB-ZK Corrosion-resistant mortar pump product structure features

UHB-ZK series of corrosion-resistant mortar pump is a cantilever single-stage single-suction centrifugal pump, made of steel-lined UHMWPE with excellent corrosion resistance and excellent wear resistance. Now BODA to introduce UHB-ZK corrosion-resistant wear-resistant mortar pump product structur...Read more -

How to adjust slurry pump speed ?

There are three methods to adjust the slurry pump speed, for your reference.1.Variable frequency speed regulation. Using frequency conversion governor, by changing the current frequency to change the rotational speed of the motor, and then change the speed of the slurry pump. The advantage of thi...Read more -

Slurry pump safe operating procedures

1, before the inspection 1) Check the direction of rotation of the motor is consistent with the direction of rotation of the pump (please refer to the corresponding model instructions). In the test motor rotation direction, should be a separate test motor, must not be connected with the pump...Read more -

The high lift slurry pump problems and solutions

1.issue: lift less than. High lift slurry pump because the pump cavitation may be inadequate or insufficient, the motor speed impeller wear caused serious.solution: such as the lower pump installation position, or increase the height of the liquid at the inlet of the pump, and timely replacemen...Read more -

How to Be Bigger and Stronger in the Era of Information Explosion of Slurry Pump Industry?

Today’s society is in an era of information explosion, and slurry pump industry products can hardly be avoided to meet competitors and the industry competition, it is a good thing for some enterprises of slurry pump. Because of the competition, the slurry pump company can improve quality of...Read more -

Iron Ore MIning Processing

Iron ore mining processing is a process which removes the gang particles like Alumia, Silica from the Iron Ore. Metal slurry pump as a main product for Iron Ore mining must be abrasive, corrosive, efficient and cost-saving.Read more -

Gold Mining Processing

In placer mines, the gold is recovered by gravity separation, for hard rock mining, other methods are usually used. Rubber slurry pumps are usually used in gold mining processing, with rubber volute liner insert and rubber impeller.Read more -

Cooper Mining Processing

Copper extraction techniques refers to the methods of obtaining copper from its ores, as well as consist of a series of chemical, physical, and electrochemical process. Rubber slurry pump are used in abrasive & corrosive conditions.Read more -

Molybdenum Mining Processing

The process of molybdenum mining depends on the laws in the locations within the country where veins of ore have been discovered.Metal slurry pumps are used for abrasive conditions, whereas rubber rubber slurry pumps are used for corrosive conditions.Read more