8/6 Rub Rub

ShuRry Pumper e ka bapala karolo ea bohlokoa haholo ts'ebetsong ea pompo ea slurry. Ka ho potoloha, ho ka thusa ho fofa pompo ho bona litlhoko tsa lisebelisoa. Ho bonolo hore pompo ea pompo e be bonolo hore re tsoele pele, kahoo re batla lisebelisoa tse khethehileng ho lelefatsa bophelo ba moemphera.

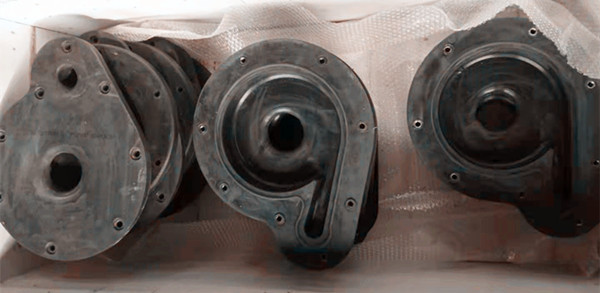

RabaraPompo ea SlurryBa susumetsang ba susumetsang li sebelisetsoa ho sebetsana le slurry e matla ka likaroloana tse blunt. Li entsoe ka rabara tsa tlhaho, tsa rabara, tsa ralikollo, epdm rabera, sethunya sa ntitle, sethunya sa ntioroelaset, Polyureurethane kapa mang kapa mang ha o hlokahala.

Ka boikhohomoso re etsa litšila tsa litšila tsa rabara tse matlafatsang le likarolo tse ling tsa ho khutlisa litlolo tse ling tsa likhomo tse tummeng, tse sa tsitsang ho fetola setoko.

Re etsa tšepe,High Churry Pomp Kampoller, kapa ba susumetsang ba khethiloeng. Hajoale, re ke ke ra hlahisa baetsi ba rona ba khothalletsang feela, empa hape ba ka etsa boholo bo bong ba baetsi ba ba baetsi ba ba baetsi ba ba baetsi ba bahanyetsi le lintho tse bonahalang ka oli

Bomabel Rubber Slurry Pompo Lits'oants'o tsa Boitsebiso:

1. BDR08 ke rabara ea tlhaho ea tlhaho ea ka thata ho ea mahareng. Bdr08 e sebelisetsoa ba susumetsang ba susumetsang moo ho ha ha ha ha ha ha ha ha ha ha ha ha ha ha ha ha hahileng. Ho thatafala ha bdr08 ho etsa hore e hanyetse haholoanyane ho roala le ho qhibiliha (ke hore: katoloso e bakoang ke matla a centrifugal) a bapisoang le bdr26. BDR08 hangata e sebelisoa feela bakeng sa basetsi

2. BDR26 ke rabara e ntšo, e bonolo ea tlhaho. E na le khanyetso e phahameng e phahameng ho lisebelisoa tse ling tsohle tse tsoang likopi tse ntle tsa tšebetso. Li-Antioxidants le li-antibegram tse sebelisitsoeng BDR26 li ntlafalitsoe ho ntlafatsa bophelo ba polokelo le fokotsa lihlong nakong ea tšebeliso. Khatiso e phahameng ea BDR26 e fanoa ke ho hlophisoa ha eona e phahameng, matla a phahameng le ho ba thata.

3. Elatomer BDS12 ke rabara ea synthetic e sebelisoang lits'ebetsong tse amanang le mafura, oli le marako. BDS12 e na le khanyetso ea khoholeho e lekaneng.

Likarolo tsa Pump tsa Slurry

Likarolo tsa pompo ea Slurry tse nang le metsi a mangata li kenyelletsa mohopolo, Volit, Shaft, Shaft Sleeve, sekhele Plate Lineer. ..

1.Centrifugal Slurry Pumps le likalaloana tsa phomolo li ka ikamahanya le lebitso la lefatše le tsebahalang.

2.Bopa pumps ke tsa moaho oa ts'ebetso ea mesebetsi e boima, e etselitsoeng ho pepeta li-sluries tse arolang haholo le tse khutsitseng.

3. Li na le khetho e fetang eo u e hatellang e hanyetsanang le li-elattle esele e nang le li-elastomer

4.Wary -Rear "ea tšepe ea tšepe le raese e fumanehang

Boitsebiso ba 5.Sal: Gland tial, tšusumetso ea tiiso le tiiso

6.Can e kentsoe letoto la li-multistage

7.easy ho hlokomela

Thepa ea thepa ea rabara:

Re na le mefuta e fapaneng ea rabara ea tlhaho le li-elalamememe tse ka sebelisoang bakeng sa ho tsamaisa lijalo tse khutsitseng kapa tsa acid. Empa lisebelisoa tsa rabara ha lia nepahala bakeng sa liluloana tse nang le li-sothud tse bohale.

Ha makhasi a na le likaroloana tse ntle, lisebelisoa tsa rabare li hlahisa ts'ebetso e ntle e thibelang ho hanyetsoa.

Thepa ea tšepe e tšoeu ea chrome e tšoeu.

Re na le lifate tse tšoeu tsa chorome tse tšoeu tse phahameng.

Li ka fana ka ts'ebetso e ntlehali tlas'a maemo a khofufatsang. Leseli le ka sebelisoang ka nepo ho mefuta e fapaneng ea li-slurry. Ho hanyetsa phahameng ho apara ka sesosa se fanoeng ke ho ba teng ha li-carbites tse thata ka har'a likokoana-hloko. Ho boetse ho lokela ho kopanngoa le ho sebelisa chelete e ngata haholo ho sebelisa moo ho hanyetsa moo ho hanyetsa moo ho hlokahalang.

Service Service

Ho latela lilemo tse ngata tsa boiphihlelo bo monate ka ho tšela le ho hlophisa ha Bodry Pompo, Boda ba etsa tloaelo ea khethollo ea pompo le likarolong tsohle tse fapaneng. Likarolo tsa pompo ea li-slurry li ka etsoa ka thepa e fapaneng ho latela tlhokahalo ea moreki, joalo ka: Lehalallo la Boithuto ba Moreki, la Hasstoy Alloy, A (6 1) joalo-joalo.

Khamphani ea rona e etsa moralo, ts'ebetso le phetoho ea likarolo tse fapaneng tse khethehileng tsa pompo. Ho latela litlhoko tsa mosebelisi, fektheri ea Boda e ka etsa lisebelisoa tse fapaneng le likarolo tsa ho fihlela litlhoko tsa maemo a fapaneng a ho sebetsa. Kapa ho latela litlhoko tsa mosebelisi ho phetoho ea theknoloji e le 'ngoe ea lisebelisoa, e kopantsoeng le mofuta oa k'hamphani ea rona ea Hydraulic, ka komporo e tsoetseng pele ea komporo e phethahetseng le e sebetsang.

Kopo:

Likarolo li sebelisoa haholo likopo tse kholo: Mesebetsi e matla ea methapo ea masapo le pampiri ea manyalo a marang-rang a patehileng Ho sebetsa ho phatloha ka tšepe ho ntsha ka nokeng e matla ea ho hana Steel Palter Palter oa Chemik Power FGD FRAD FRAD FRAD CRMANENG CARKANT CARD CORT CORT CORT CORT CORT CORT CORT CORT CORT CORCT CORT CORT CORT CORT CHEMA