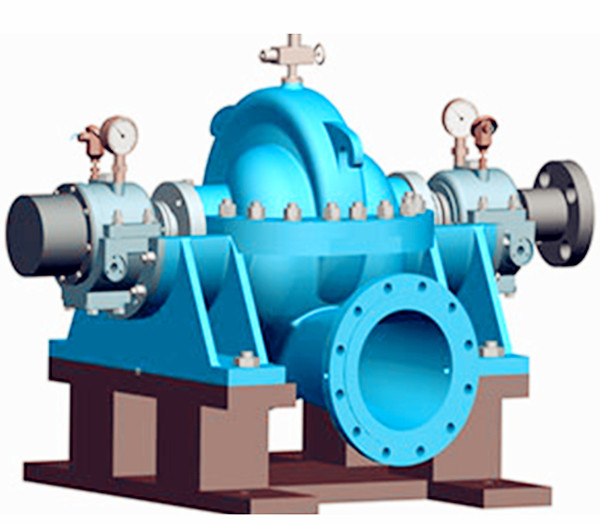

XSR e chesa ea metsi a nang le metsi a nang le metsi

Tlhaloso ea pompo

Xsr Series 1 Comple Suction Case e arotsoe ka ho khetheha e hlophisitsoe ka ho khetheha bakeng sa ho fetisetsa metsi a limela tsa mocheso. Pump bakeng sa marang-rang a mocheso oa masepala o tla leleka phallo ea metsi joalo ka sekwerekeng. Metsi a potoloho a phallang ho tsoa marang-rang a mocheso oa masepala a tla ntlafatsoa ke pompo ebe o isoa marang-rang a mocheso oa masepala.

Maemo a mantlha a ts'ebetso

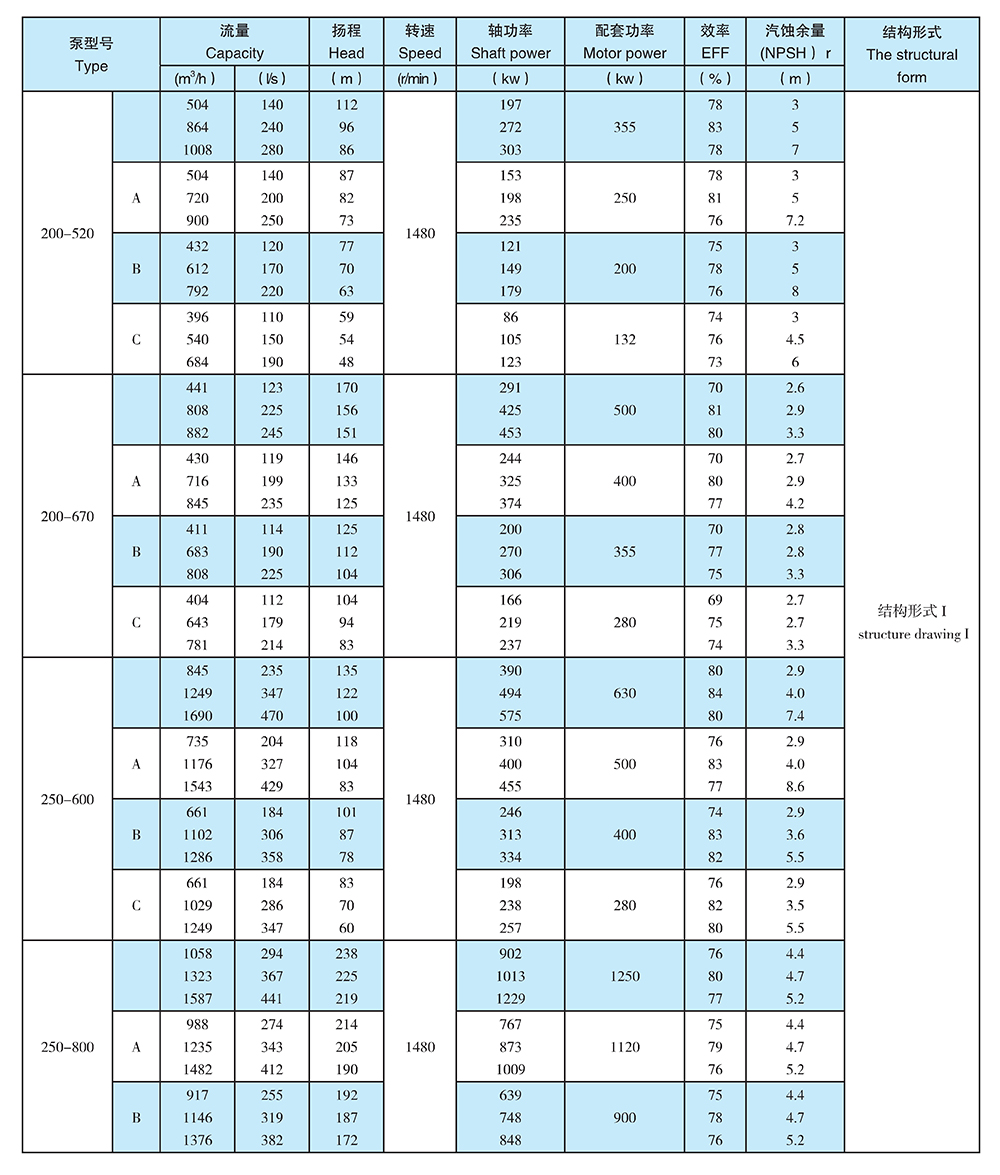

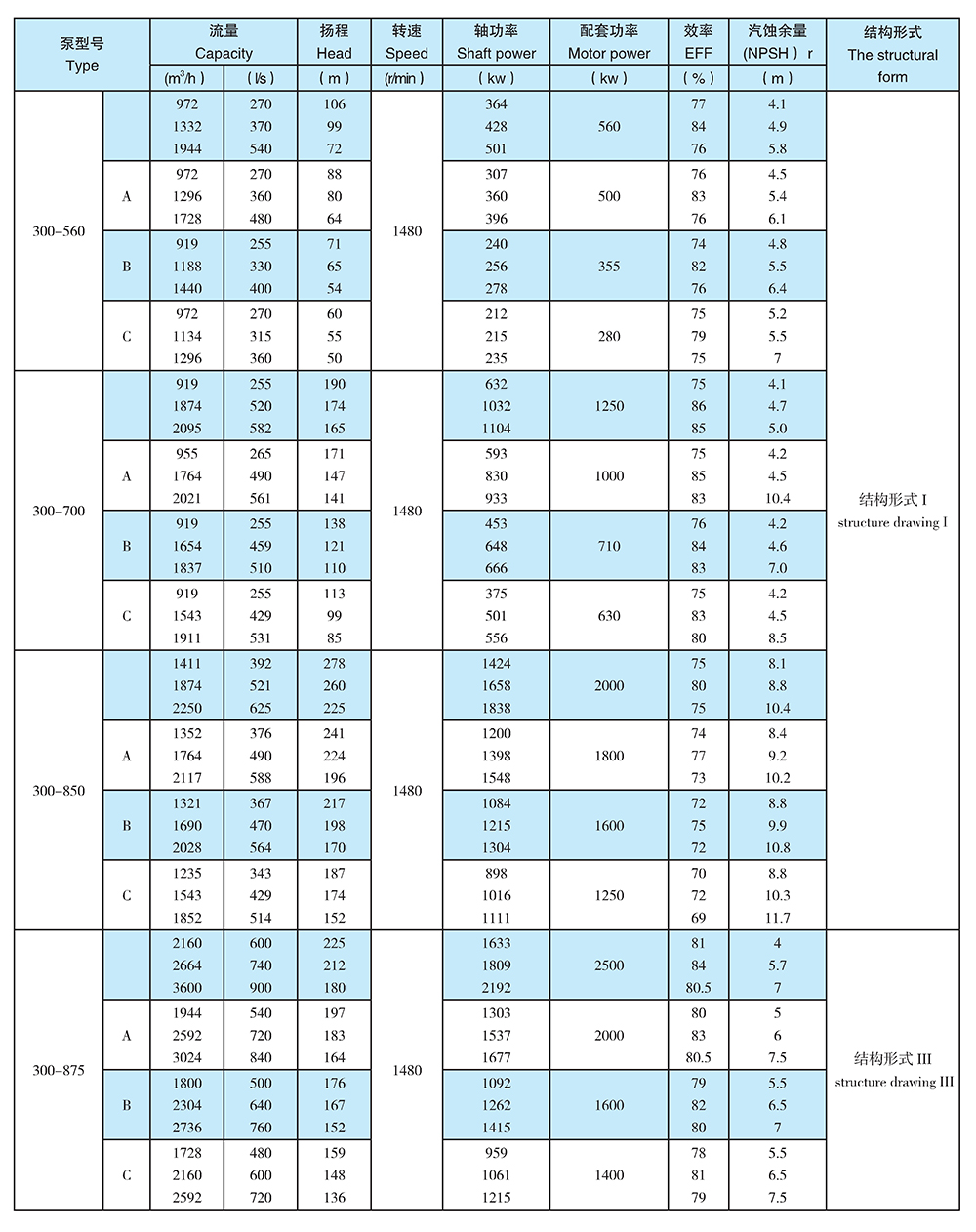

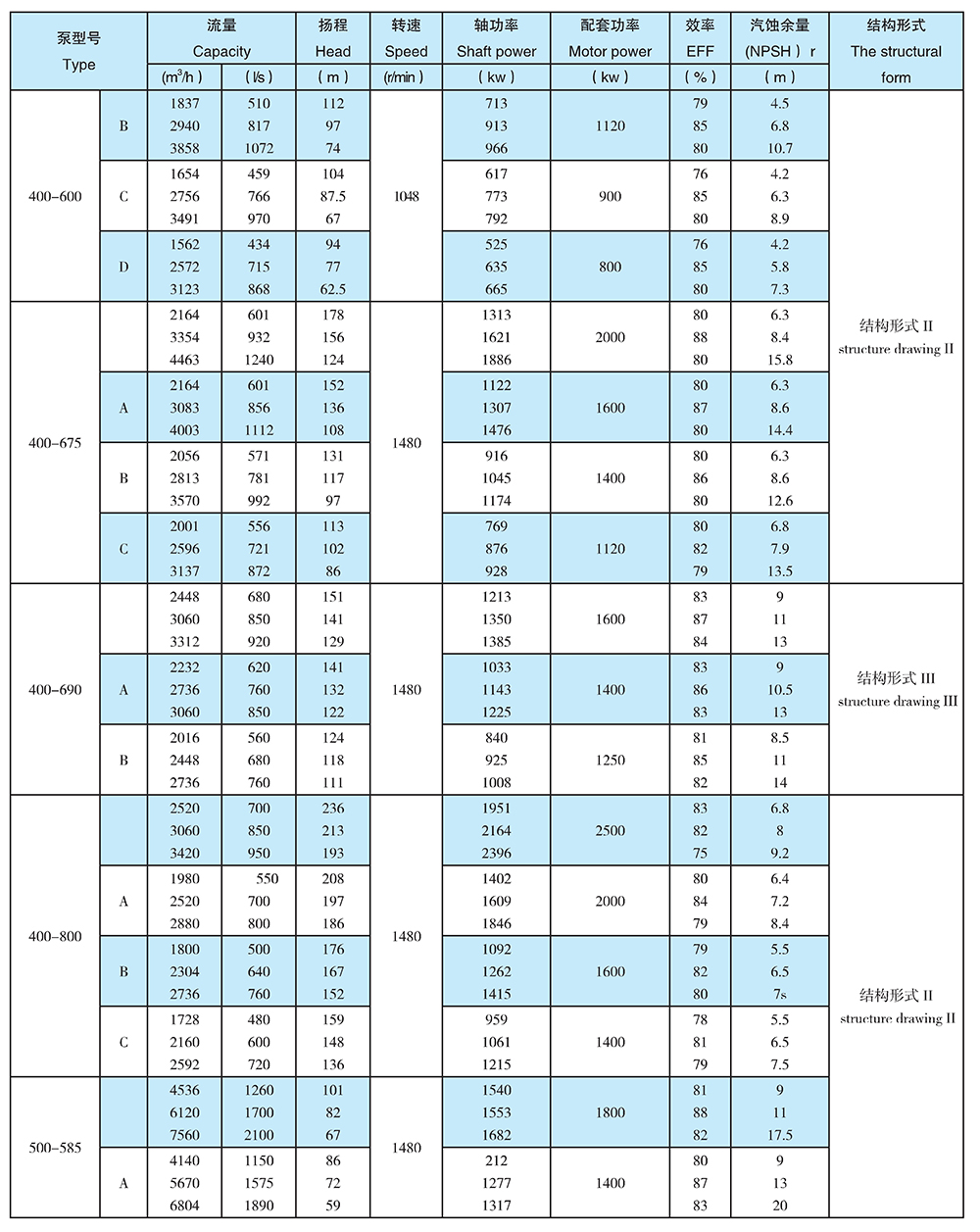

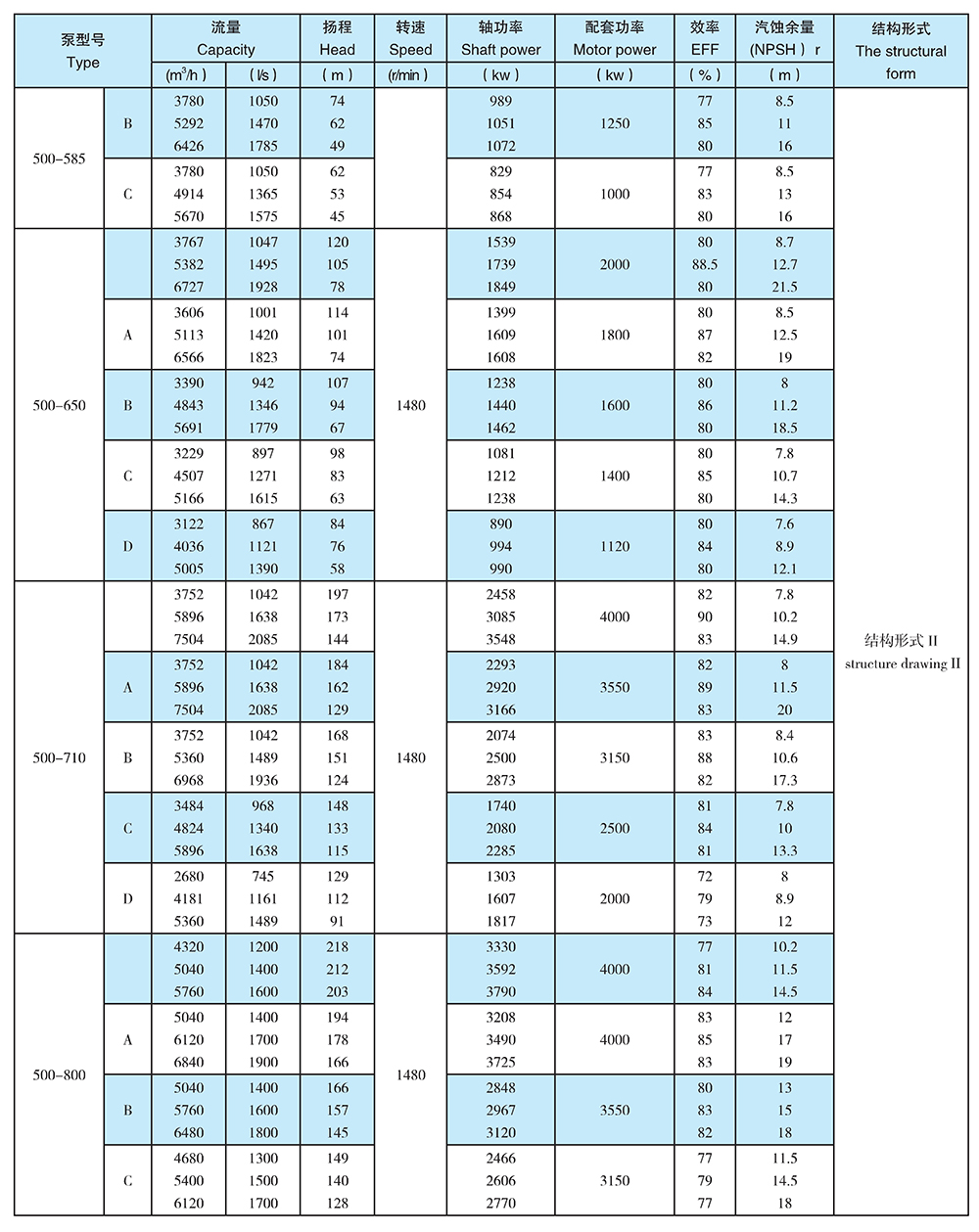

● Bopump Oundlet den: 200 ~ 900mm

● Exakity Q: 500-50003 / h

● Hlooho H: 60-220m

● Mocheso oa T: 0 ℃ ~ 200 ℃

● Karolo e tiileng ea paramente e tiileng ≤80mg / L

● Khatello e lumelletsoeng ≤4MA

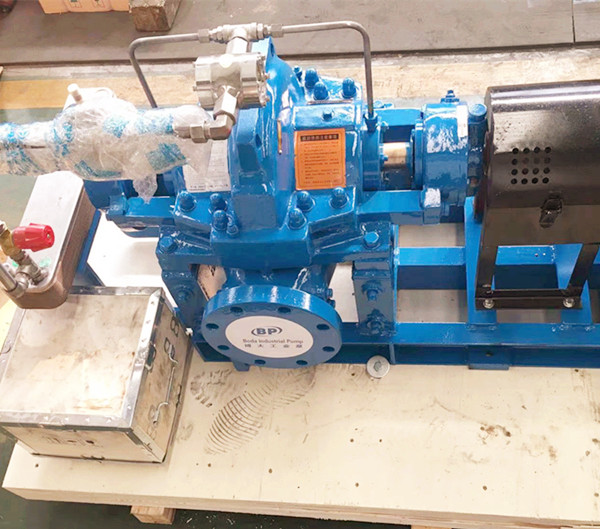

Odara e hlophisitsoeng e nang le pompo ea ho potoloha ka ho futhumatsa marang-rang

Tlhaloso ea mofuta oa pompo

Mohlala: XS R250-600Axsr:

250: Pompo e tsoaletsoe ka bophara

600: Boameter e tloaelehileng ea motsamaisi

A: E fetotsoe ka ntle ea moetsi oa sebopeho (Max bophara ba Max ntle le letšoao)

Lenane le khothalelitsoeng bakeng sa likarolo tsa mantlha:

Casing: Qt500-7, Zg230-450, ZG1cr13, Zg0ZR19ni10

Impeller: Zg230-450, ZG2cr13, Zg08CR19ni10

Shaft: 40cr, 355 commo

Shaft Sleeve: 45,2cr13,0cr3ni10ni10

Roala selikalikoe: QT500-7, Zg230-450, Zcc5Pb5zn5

Ho beoa: skf, NSK

Karolo ea sebopeho sa pompo

1: Mofuta oa XSR XSR o sebetsa ka lerata le lerata le bobebe, ka lebaka la ho phatloha ha makhutšoaane lipakeng tsa tšehetso.

2: Tsela e tšoanang ea lipina tsa XSR ea XSR e ka sebetsoa ka tsela e fapaneng ho qoba tšenyo ea lipompo ka hamore ea metsi.

3): Moralo o ikhethang oa foromo e phahameng ea mocheso: metsi a pholileng a pholileng a ka ba teng ho tloha ka ho phela ka kamore e futhumatsang; Ho khomarela oli ka oli kapa mafura, haeba sebaka seo sa marang-rang se na le metsi a tsoang ho 1-25 / cm2 e amanang le maemo a kaholimo a sa fumanehe, ka kopo latela thupelo e latelang: Ho futhumala le ho chesa mocheso o phahameng oa pompo ho felisa li-timp tse tsoang sethaleng ho tloha sethaleng se tsoang botebong ba pelo. Letšoao la metsi le lokela ho ts'oaroa sistimi ea metsi a flush le ho lokisa metsi le khatello ea metsi. Bimetal Thermometer e lokela ho ba hammoho le ka morao ho sefuba, 'me sesebelisoa se tšosang, se neng se ka hlola ha mocheso o feta moeli; Hape, st strib se fapaneng sa khatello e ne e le boikhethelo, e neng e tla beha leihlo la lejoe la lejoe la lejoe. Ka holim'a moralo o ikhethang o etsa hore pompo e sebetse ka maemo a mocheso o phahameng haufi le Centigrade ea 200

4: Sesebelisoa sa ho fumanoa ka potlako hammoho le sesebelisoa sa ho lekanya le lebelo le tla hlophisoa maemong a katoloso ea shaft haeba pompo e tsamaisoa ke koloi kapa seretse se chesang; Omelo bokhoebi e tla hlophisoa sesebelisoa sa ho kopanya haeba pompo e tsamaisoa ke koloi e tloaelehileng e nang le ho co sayed.

5: Mofuta oa Xsr Xsr E ka sebelisa litiiso tsa katse, kahoo ho bonolo haholo ebile e bonolo ho li nkela sebaka.

6: Ha moralo oa indasteri, kemiso ea XSR e hlakile ebile e ntle ho latela li-aesthetics tsa sejoale-joale.

7: Ho sebetsa hantle ha lipompo tsa XSR ke 2% -3% e phahame ho feta ho amohela mohlala oa Hydraulic 'me ka hona fokotsa litšenyehelo tsa ts'ebetso haholo.

8: Ho khetha ho kenya letsoho ho kenya letsoho, le likarolo tse ling tse khethiloeng ke moreki, etsa hore pompo e be e loketseng

bakeng sa boemo bofe kapa bofe ba ts'ebetso le ho fokotsa litšenyehelo tsa tlhokomelo.

9: Ke potlakile ebile re le bonolo ho bokella likarolo tsa rotor ka lebaka la ho sebelisa sepakapaka sa Ellast.

10: Ha ho hlokahale hore u etse phetoho ho tumello efe kapa efe ha e kopana.

PUMELE EA BOTSOALLE