Sehlahla sa pump

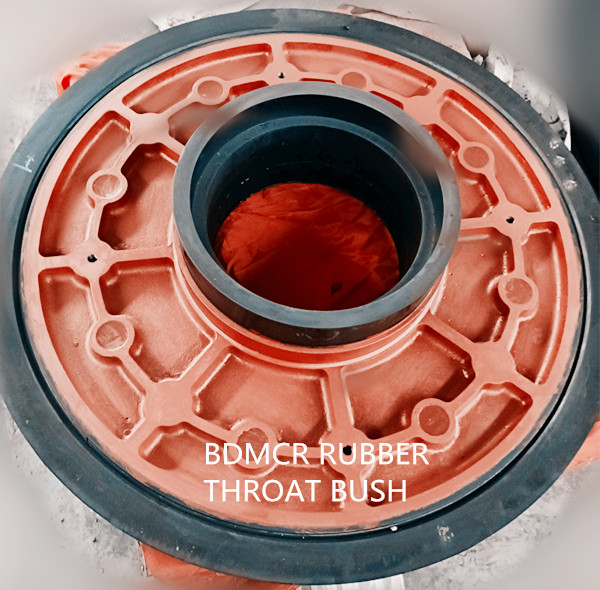

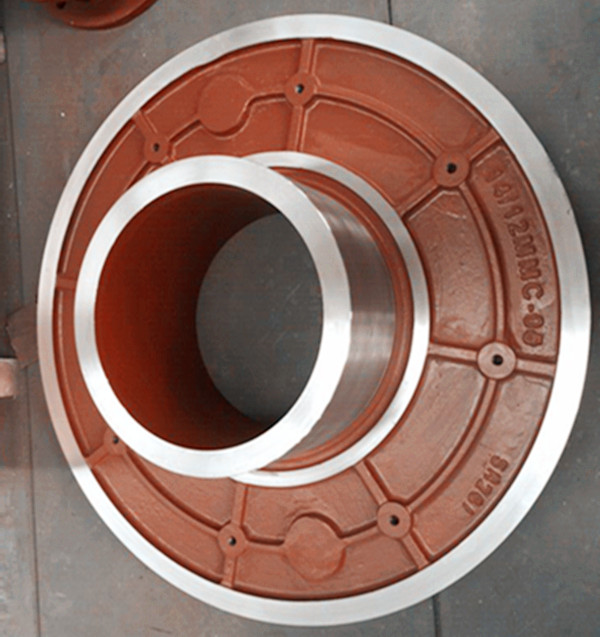

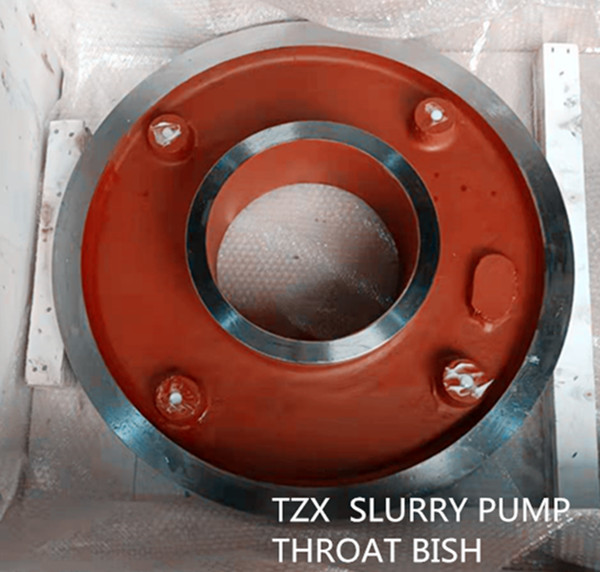

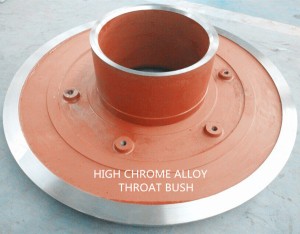

Likarolo tsa li-centrifiFuf tsa pompo ea pompo - sehlahla sa 'metso

Ka pele le ka morao li-stroud li pomme litloholo tse fokotsanyang le tšilafalo ea tiiso. Metal ea tšepe e thata le e nang le li-elastomer e se nang matla.

Khoutu ea Slurry Pomp ea karohano: BDE4083, BDF6083, BDF8083.

Slurry Pomp

Polyurethane:

U01 ke lisebelisoa tse loantšanang tse loantšanang tse sebetsang likopo tsa elattletoer moo 'Tramp "ke bothata. Sena se hlahisoa ke matla a phahameng le matla a holimo a U01. Leha ho le joalo, ho hanyetsa ka kakaretso ho hanyetsa ha eona ho tlaasana le rabara ea tlhaho.

Lisebelisoa tse hlophisitsoeng:

PUP e lula e etsa boiteko bo tsoelang pele ea lisebelisoa, Helpalon, Bronze, Bronze, Bronjus

Material: Cr26, Cr27, Cr30, BR08, BR24, BR26, BR33, BR38, BR55, BR66, BS31, BS42, BS02, BS21, BS44...

1. Bda05Na tšepe e tšoeu e hanyetsanang e fanang ka ts'ebetso e ntlehali tlasa maemo a itšehlang. Leseli le ka sebelisoang ka nepo ho mefuta e fapaneng ea li-slurry. Ho hanyetsa haholo ha allow bda05 ho fanoa ke ho ba teng ha li-carbites tse thata ka har'a sebopeho sa eona. Alloy A05 o tšoaneleha ka ho khetheha lits'ebetsong moo ho hanyetsanang le moea o nang le corrosance, hammoho le ho hanyetsa ka thata ho hlokahala.

2. Bda07Marten-stic tšepe e tšoeu e nang le khanyetso e lekaneng ea khoholeho.

3. Bda49e loketse mesebetsi ea Pressunion ea Pressunion, moo ho roala ka matla le hona ho leng bothata. Lebelona le tšoaneleha haholo bakeng sa feshene ea khase ea khase (FGD) le lits'ebetso tse ling tse khutsitseng. Leseli le ka tlase ho 4.BDA49 le na le khanyetso ea kholeho e ts'oanang le ea ni- Thata 1.

Likarolo tse kholo tsa pompo ea Slurry:

• moetsi- Ka pele le ka morao li-stroud li pomme li-vaenes tse fokotsa ho pheta-pheta le tšilafalo ea tiiso.

Li-moimpoli tse thata tsa tšepe le tse nang le bo-rabara tse ngata li ka botlalo. Ho lahlela likhoele tse sa sebetseng, ho hloka lintho tse ling kapa linate. Ts'ebetso e phahameng le meralo e phahameng ea hlooho e fumaneha.

• li-liners- Li-liners tse se nang palo li tsoaloa, ha li tšoaroe, ho ea ho ho hatakela sehokelo se setle le boiketlo ba tlhokomelo. Li-thowers tse thata tsa tšepe li tsitsitse ka ho felletseng ka khatello e sithabetsang. Elastomer

tiiso ea tiiso ho khutlisa manonyeletso kaofela.

• sehlahla sa 'metso -Roala ho fokotseha 'me ho lokisoa ho nolofalitsoe ke tšebeliso ea lifahleho tse tenang ho tlama lintho tse ntle tse khahlisang nakong ea kopano le ho tlosoa ka mokhoa o bonolo.

• Kopano e behang -Shaft e kholo e nang le tšollo e khutšoane e fokotsa ho khoptjoa ebile e tlatsetsa bophelong bo monate. Ke tse 'ne feela ka li-bolts li hlokahalang ho tšoara thapo ea kankere ea mokotla.

Likarolo tsa Pump tsa Slurry

Likarolo tsa pompo ea Slurry tse nang le metsi a mangata li kenyelletsa mohopolo, Volit, Shaft, Shaft Sleeve, sekhele Plate Lineer. ..

1.Centrifugal Slurry Pumps le likalaloana tsa phomolo li ka ikamahanya le lebitso la lefatše le tsebahalang.

2.Bopa pumps ke tsa moaho oa ts'ebetso ea mesebetsi e boima, e etselitsoeng ho pepeta li-sluries tse arolang haholo le tse khutsitseng.

3. Li na le khetho e fetang eo u e hatellang e hanyetsanang le li-elattle esele e nang le li-elastomer

4.Wary -Rear "ea tšepe ea tšepe le raese e fumanehang

Boitsebiso ba 5.Sal: Gland tial, tšusumetso ea tiiso le tiiso

6.Can e kentsoe letoto la li-multistage

7.easy ho hlokomela

Thepa ea thepa ea rabara:

Re na le mefuta e fapaneng ea rabara ea tlhaho le li-elalamememe tse ka sebelisoang bakeng sa ho tsamaisa lijalo tse khutsitseng kapa tsa acid. Empa lisebelisoa tsa rabara ha lia nepahala bakeng sa liluloana tse nang le li-sothud tse bohale.Ha makhasi a na le likaroloana tse ntle, lisebelisoa tsa rabare li hlahisa ts'ebetso e ntle e thibelang ho hanyetsoa.

Thepa ea tšepe e tšoeu ea chrome e tšoeu.

Re na le lifate tse tšoeu tsa chorome tse tšoeu tse phahameng.

Li ka fana ka ts'ebetso e ntlehali tlas'a maemo a khofufatsang. Leseli le ka sebelisoang ka nepo ho mefuta e fapaneng ea li-slurry. Ho hanyetsa phahameng ho apara ka sesosa se fanoeng ke ho ba teng ha li-carbites tse thata ka har'a likokoana-hloko. Ho boetse ho lokela ho kopanngoa le ho sebelisa chelete e ngata haholo ho sebelisa moo ho hanyetsa moo ho hanyetsa moo ho hlokahalang.

Service Service

Ho latela lilemo tse ngata tsa boiphihlelo bo monate ka ho tšela le ho hlophisa ha Bodry Pompo, Boda ba etsa tloaelo ea khethollo ea pompo le likarolong tsohle tse fapaneng. Likarolo tsa pompo ea li-slurry li ka etsoa ka thepa e fapaneng ho latela tlhokahalo ea moreki, joalo ka: Lehalallo la Boithuto ba Moreki, la Hasstoy Alloy, A (6 1) joalo-joalo.

Khamphani ea rona e etsa moralo, ts'ebetso le phetoho ea likarolo tse fapaneng tse khethehileng tsa pompo. Ho latela litlhoko tsa mosebelisi, fektheri ea Boda e ka etsa lisebelisoa tse fapaneng le likarolo tsa ho fihlela litlhoko tsa maemo a fapaneng a ho sebetsa. Kapa ho latela litlhoko tsa mosebelisi ho phetoho ea theknoloji e le 'ngoe ea lisebelisoa, e kopantsoeng le mofuta oa k'hamphani ea rona ea Hydraulic, ka komporo e tsoetseng pele ea komporo e phethahetseng le e sebetsang.

Kopo:

Likarolo li sebelisoa haholo likopo tse kholo: Mesebetsi e matla ea methapo ea masapo le pampiri ea manyalo a marang-rang a patehileng Ho sebetsa ho phatloha ka tšepe ho ntsha ka nokeng e matla ea ho hana Steel Palter Palter oa Chemik Power FGD FRAD FRAD FRAD CRMANENG CARKANT CARD CORT CORT CORT CORT CORT CORT CORT CORT CORT CORCT CORT CORT CORT CORT CHEMA