Letoto la TZM TZS Slurry Pump

Tšebeliso le Likarolo:

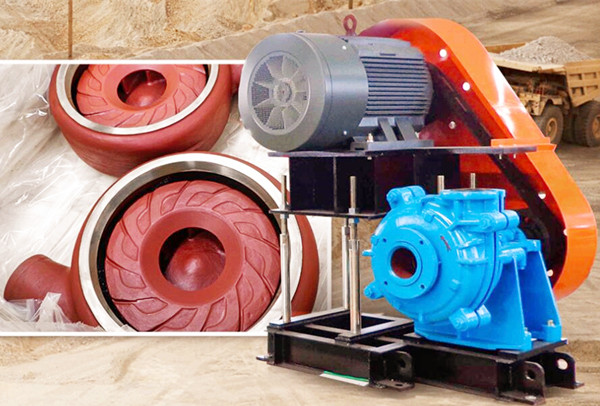

Mofuta oa TZM, TZS, lipompo tsa slurry li cantilevered, rapameng, centrifugal slurry pumps. Li etselitsoe ho sebetsana le li-slurry tse nang le abrasive, high density slurries makaleng a metallurgical, morafo, mashala, matla, thepa ea mohaho le mafapha a mang a indasteri joalo-joalo. type e ka boela ea kenngoa lenaneong la multistage.

Lipoleiti tsa foreimi tsa mofuta oa TZM, lipompo tsa TZS li na le lilara tsa tšepe tse sa senyeheng kapa lithapo tsa rabara. Li-impeller li entsoe ka tšepe kapa rabara e sa cheng.

Li-shaft seal tsa mofuta oa TZM, TZS, lipompo li ka amoheleha ka gland seal kapa expeller seal. Lekala la ho qhala le ka behoa ka nako ea likhato tse 45 ka kopo le ho lebisoa maemong afe kapa afe a robeli ho lumellana le ho kenngoa le lisebelisoa.

Kenyelletso e Khutšoanyane ea Khetho ea Mofuta oa Pompo:

Ha ho buuoa ka li-curve tsa ts'ebetso ea pompo, mefuta e khethiloeng ea bokhoni e lokela ho ba ka tsela e latelang:

Mofuta oa Pompo TZM, TZS: 40-80% bakeng sa sets'oants'o se phahameng, li-slurries tse matla tse hlabang

40-80% bakeng sa sets'oants'o se mahareng, li-slurries tse hlabang tse mahareng

40-120% bakeng sa sets'oants'o se tlase, li-slurries tse hlabang tse tlase

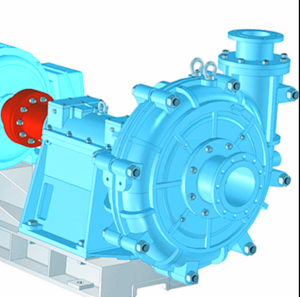

Sebopeho sa Pompo:

Mohaho oa likhase tse peli.E na le sebopeho sa ts'ebetso e phahameng, abrasion e phahameng, ts'ebetso e tsitsitseng le phetoho e babatsehang.

Thepa ea liner le impeller e amoheloa bakeng sa alloy e phahameng ea chrome e sa sebetseng kapa rabara, lekala la discharge le ka beoa maemong a 8 a fapaneng.

ka nako ea 45 °, lipompo li ka 'na tsa kenngoa ka mekhahlelo e mengata, mohlomong li tsamaisoa ke lebanta kapa ho kopanya ka ho toba.

Setiiso sa shaft se ka amohelwa ka tšoelesa seal, expeller seal kapa mechanical seal.

Lipompoe lokela ho pota-pota ho shebella ho tloha moo u khannang teng.

Kopo:Lipompompe li loketse ho fana ka li-slurries tse nang le abrasive, high density slurries liindasteri tsa metallurgical, tsa merafo, tsa mashala le tsa matla, joalo-joalo, mohlala, li-ore, middings, concentrates, tailings merafong ea ferrous le e seng ferrous.

Lethathamo la Ts'ebetso:

| Mofuta | Bokhoni ba Q(m3/h) | Hlooho H(m) | Lebelo (r/min) | Max.eff(%) | NPSHr (m) | E lumelletsoe max.boholo ba karolo (mm) |

| 25TZS-PB | 12.6-28.8 | 6-68 | 1200-3800 | 40 | 2-4 | 14 |

| 40TZS-PB | 32.4-72 | 6-58 | 1200-3200 | 45 | 3.5-8 | 36 |

| 50TZS-PC | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 48 |

| 75TZS-PC | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 63 |

| 100TZS-PE | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 51 |

| 150TZS-PR | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 100 |

| 200TZS-PST | 612-1368 | 11-61 | 400-850 | 71 | 4-10 | 83 |

| 250TZS-PST | 936-1980 | 7-68 | 300-800 | 80 | 3-8 | 100 |

| 300TZS-PST | 1260-2772 | 13-63 | 300-600 | 77 | 3-10 | 150 |

| 350TZS-PTU | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 160 |

| 450TZS-PTU | 520-5400 | 13-57 | 200-400 | 85 | 5-10 | 205 |