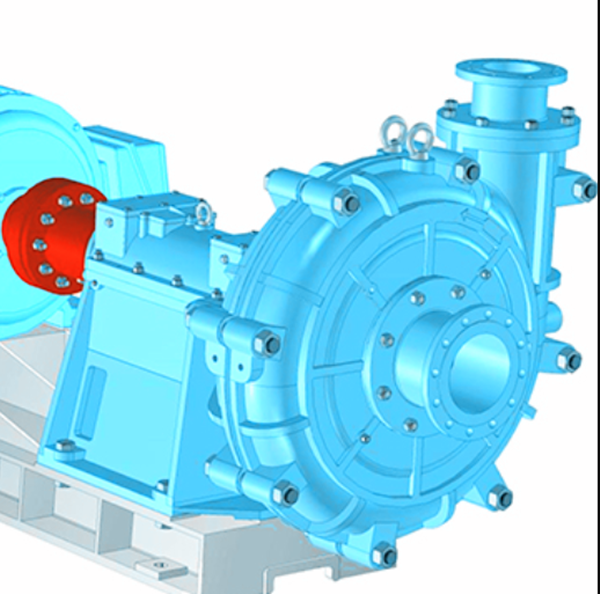

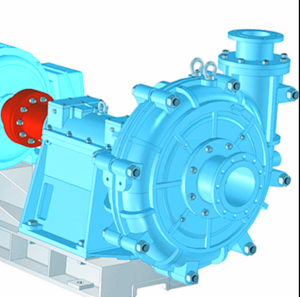

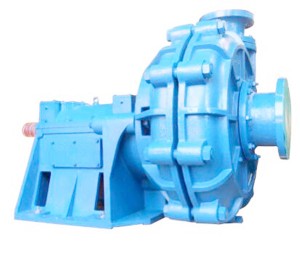

Ketik zgb (p) pompa slurry

Panggunaan Fungsi:

1. Kinerja hidrazik maju, desain modern, efisiensi tinggi sareng laju abrasiit handap2. Petikan lega, non-clogging sareng pagelaran anu saé.3. Sépot ékspeller digabungkeun sareng segel bungkus sareng segel mékanis kedah diadopsi pikeun ngajamin slurry ti bocor.4. Desain reliabilitas mastikeun mtbf panjang (hartosna waktos antara kajadian)5. Ngalangkungan métrik nganggo lubrication minyak, sistem anu berrasa pelincir sareng mastikeun mastikeun anu tiasa dioperasikeun dina operasi handap.

6.TET bagian bagian baseuh ngagaduhan kamampuan anu saé tina bahan anti, anti korupna, pompa ieu tiasa dianggo pikeun korosasi gelas bumi, sareng kekectionasi kripaty.

7. Aktip tiasa dioperasikeun dina séri sareng panggung dina tekenan anu diidinan. tekanan kerja anu diidinan nyaéta 3.6 mpa.

Séri fratfe gaduh kauntungan tina konstruksi anu tiasa penting, épencanan anu tinggi sareng pangropéa gampang. Éta tiasa loba dianggo pikeun nanganan campuran anu ngandung tina mung gaya anu abrani sareng korosip dina kakuatan listrik, goptallge, hiji bahan pangwangunan.

Fitur pompa:

1. Serieri ZGB (P) Pompa bubur nyaéta horizontal, panggung tunggal, nyeuseup jempol atanapi samentil, compry slurry. Pompa diputer dina jam anu ditingali tina tungtung drive.

2. Bagean baseuh zgb sareng prompet zgbp dina diaméter outlet anu sami tiasa diukeurkeun. Ukuran pamasangan ngagariskeun hiji sareng sami. Pikeun bagian drive ngeunaan hal seri ZGB (di kembang slurry bubur, bentuk pamisahan horisontal kalayan lublikasi minyak sareng dua sét-set cai anu ditengékeun sareng di luar. Upami diperyogikeun, cai pendingin tiasa disayogikeun. Gabungan anu disiapkeun pikeun cai pemanasan sareng tekanan cai pendingin tiasa katingal dina méja 1.

3. Dua jinis segel cloweler-aci-digabungkeun ku segel pembungkus sareng mékanis parantos dianggo pikeun séri ZGB (p) pompa slurry.

4. Segel mékanis anu dilereskeun pikeun cai anu nutup tinggi ditingal nalika pompa slurry anu dioperasikeun dina séri (dua péri leuwih di luhur.

Padsikan tabel pagelaran:

|

Model | Laju n (r / mnt) | Kapasitas Q (l / s) | Sirah H (m) | Max.ff. | Npsh | Aci Kakuatan (kW) | Impel Dia (mm) | Beurat pompa (kg) | Outlet / Inlet (mm) | |

| 65zgb | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | 390 | 1850 | 65/80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| 80zgb | 980 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | 80/100 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | Sudut 400 | ||||

| 740 | 31.0-15.4 | 26.1-27.3 | 66.1-48.7 | 1,5-0.8 | 12.0-8.4 | |||||

| 100zgb | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100/152 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 980 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54,5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | Sudut 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150zgb | 980 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3.8-2.7 | 215.0-165.5 | 740 | 3450 | 150/200 | |

| 740 | 151.2-75.6 | 48.611.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 980 | 182.4-91.2 | 73.0-77.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.2-84.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64,8 | 35.2-37.2 | 77.7-53.3 | 1,6-0.6 | 57.6-44,3 | |||||

| 200zgb | 980 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6,7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 980 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| 250zgb | 980 | 400.0-200.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | 700 | ||||

| 740 | 285.7-142.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300zgb | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300/350 | |

| 740 | 402.7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2.0 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-45.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |