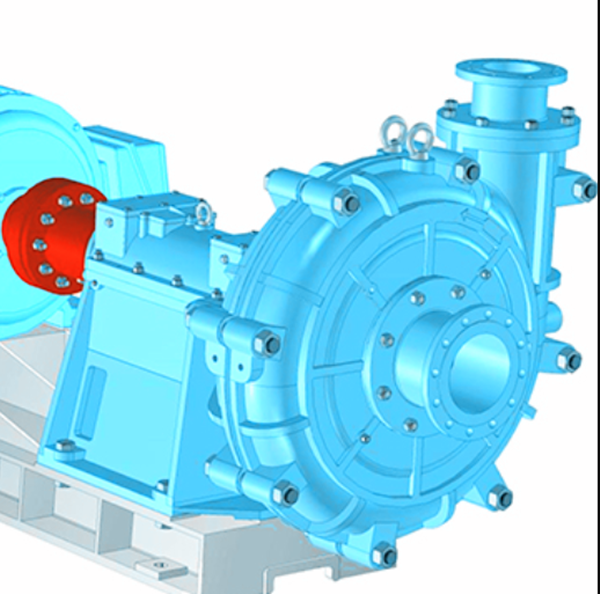

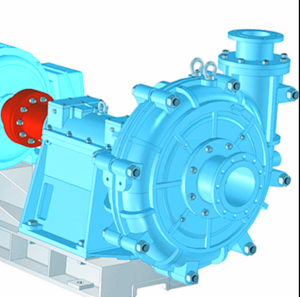

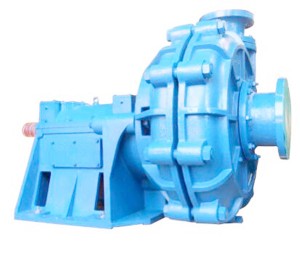

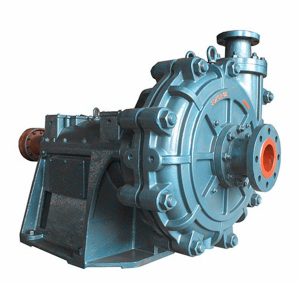

Aina ZGB (P) Bomba la Slurry

Utangulizi wa kazi:

1. Utendaji wa hali ya juu wa majimaji, muundo wa kisasa wa CAD, ufanisi mkubwa na kiwango cha chini cha abrasion2. Kifungu pana, kisicho na uhusiano na utendaji mzuri wa NPSH.3. Muhuri wa kufukuzwa pamoja na muhuri wa kufunga na muhuri wa mitambo zimepitishwa ili kuhakikisha utelezi kutoka kwa kuvuja.4. Ubunifu wa kuegemea inahakikisha MTBF ndefu (inamaanisha wakati kati ya matukio).

6. Vifaa vya sehemu zenye mvua vilikuwa na utendaji mzuri wa kupambana na kuvaa na kupambana na kutu, pampu inaweza kutumika kwa maji ya bahari-kurudisha ili kuizuia kutoka kwa kutu ya sweta, chumvi na ukungu, na kutu ya umeme.

7. Pampu inaweza kuendeshwa mfululizo na hatua nyingi ndani ya shinikizo linaloruhusiwa. Shinikiza inayoruhusiwa ya kufanya kazi ni 3.6 MPa.

Mfululizo wa pampu una faida ya ujenzi mzuri, ufanisi mkubwa, operesheni ya kuaminika na matengenezo rahisi. Inaweza kutumiwa sana kwa kushughulikia mchanganyiko uliomo wa vimumunyisho vyenye nguvu na yenye kutu katika nguvu ya umeme, madini, mgodi, makaa ya mawe, vifaa vya ujenzi na idara za tasnia ya kemikali kwa kuondoa majivu na sludge katika kituo cha umeme.

Vipengele vya Bomba:

1. Mfululizo wa ZGB (P) pampu ya kuteleza ni ya usawa, hatua moja, ujenzi mmoja, cantilever, mara mbili-casing, pampu ya centrifugal slurry. Bomba huzunguka kwa saa inayotazamwa kutoka mwisho wa gari.

2. Sehemu za mvua za ZGB na pampu ya ZGBP kwenye kipenyo sawa cha nje inaweza kubadilika. Vipimo vyao vya usanidi wa muhtasari ni moja na sawa. Kwa sehemu ya gari ya safu ya ZGB (P), sura ya mgawanyiko wa usawa na lubrication ya mafuta na seti mbili za mifumo ya baridi ya maji ndani na nje imepitishwa. Ikiwa ni lazima, maji baridi yanaweza kutolewa. Pamoja iliyoandaliwa kwa maji ya baridi na shinikizo la maji baridi inaweza kuonekana kwenye Jedwali 1.

3. Aina mbili za muhuri wa shimoni -muhuri wa kupanua pamoja na kufunga na muhuri wa mitambo zimetumika kwa pampu ya safu ya ZGB (P).

4. Muhuri wa mitambo hutolewa na maji ya kuziba shinikizo ya juu inapendekezwa wakati pampu ya slurry inafanya kazi katika safu (hatua mbili na juu ya hatua mbili), na muhuri wa expeller pamoja na kufunga hutumiwa katika pampu ya hatua moja.

Jedwali la Utendaji wa Bomba:

|

Mfano | Kasi n (r/min) | Uwezo Q (L/S) | Kichwa H (m) | Max.eff. | NPSH | Shimoni Nguvu (kW) | Msukumo Dia (mm) | Uzito wa pampu (kilo) | Duka /ingizo (mm) | |

| 65zgb | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | 390 | 1850 | 65 /80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| 80zgb | 980 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | 80 /100 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31.0-15.4 | 26.1-27.3 | 66.1-48.7 | 1.5-0.8 | 12.0-8.4 | |||||

| 100zgb | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | 100 /152 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | 450 | ||||

| 980 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| 150zgb | 980 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3.8-2.7 | 215.0-165.5 | 740 | 3450 | 150 /200 | |

| 740 | 151.2-75.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 980 | 182.4-91.2 | 73.0-77.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | 685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.2-84.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| 200zgb | 980 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | 700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-80.0 | |||||

| 980 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| 250zgb | 980 | 400.0-200.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | 700 | ||||

| 740 | 285.7-142.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | 645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| 300zgb | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | 760 | 5500 | 300 /350 | |

| 740 | 402.7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2.0 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-45.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | 646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |