I-Ceramic Slirry Pump

I-Cemiramic Slurry Pumpters:

I-IMPOLLEROLL yeyona migca ijikelezayo ejikelezayo inesiqhelo inee-vanes zokudlulisela kwaye ikhokele kumandla amakhulu kulwelo.

I-impeller evaliweyo

Impembelelo ivaliwe ngokubanzi ngenxa yokusebenza kakuhle kwaye ayinabuncinci ukunxiba kwingingqi ye-liner yangaphambili.

Ukusebenza kakuhle iFrancis Vane

Ezinye izibonelelo zeprofayile yeFrancis vane kukusebenza okuphezulu, ukuphuculwa kwendlela yokusebenza ngokuphuculwa kwaye kunxiba kancinci ubomi kwiintlobo ezithile ze-nyibid kuba i-slid isebenza ngakumbi.

I-Concave yenziwe

I-Impleller ikhutshiwe yenziwe, uxinzelelo olujikeleze i-shrouds luya kube liphantsi, ke kuya kuba nentsebenzo engcono.

Izixhobo

Iindawo ezimanzi zenziwa nge-carabide ye-calicon ye-ceramic ngokwenza ukwenziwa kwenkungu, okuya kunika impompo yokunxiba kunye nokuchasana nokuxhathisa amasuntswana amakhulu (<15mm) kwi-slirry. Ezi zenza impompo yensimbi ayinakwenza.

-Unxibe ukunganyangeki

-Ukunyanzela ukunganyangeki

-Impembelelo yempembelelo

Kwimpompo ye-slirry, amalungu emanzilithetha iinxalenye ze-lining ezinxibelelana nemithombo yeendaba ye-fluid, ngokufuthi ibandakanya i-impleller, ivollo, iplate yesakhelo, ityholo lomqala. Kukho amalungu anokufumana ngokulula okanye anxunguphele xa esebenza kwaye ephindaphinde amathuba onke.

Ngokwesiqhelo amalungu empompo eyenziwe ngentsimbi, intsimbi, i-bronze, ubhedu, i-aluminim, njl. Njl. Njl. Kodwa i-chrome ephakamileyo kunye ne-elastomer ngoku yeyona nto iphambili kwi-pumpry pumpry. Iminyaka yakutshanje ezinye iinkampani zizama ukwenza iinxalenye ezimanzi yi-ceramics kwaye idatha emininzi ivela kwi-labs kunye neeMills zibonisa ukuba iinxalenye ezimanzi ze-ceram zinokusebenzela ixesha elide kune-chrome ephakamileyo.

Kwizixhobo ze-chrome ye-chrome, uhlobo oluqhelekileyo luluhlu oluphezulu lwe-chrome (i-27% cr), inokusetyenziswa ukusuka kwi-PH 5 ukuya kwele-12, kwaye lukhetho oluhle kakhulu kwi-SURC58, eyona nto ilungileyo kulawulo lwesilayidi kunye nezothutho. Kodwa kwezinye iimeko, i-PH ingaphantsi kwe-5, emva koko sizama i-BDA49, inokusehlisa i-PH4, isetyenziswe kakhulu kwi-FGD.

I-elastomer isetyenziswa ngokubanzi kwiimeko ezifanelekileyo zokutyibilika kunye ne-PH.

Kutshanje, iPolyurethane iyathandwa kwezinye iimeko. Kulungile kukusula kwaye unxibe iimeko.

Yintoni eyona nto ibalulekileyo ye-cerry yempompo ye-slirry igqibelele ukutshintsha i-elastomers kunye ne-polysurethane kwezinye iimeko. Ubunzima obuphezulu kunye ne-corosion enkulu yenze ukuba ithathe indawo yokutshintsha kwentsimbi kwezinye iimeko.

Ezona zinto zibalulekileyo zokumisa i-pumpry ye-pumpry yokutshintsha ezinye zexabiso kunye nobuthathaka. Kodwa ezinye iinkampani zisombulule ezi ngxaki, oko kukuthi iinkampani zenza impumelelo ekwenzeni impompo ye-cemarac inokuthi imele ifuthe ngamasuntswana kwi-fluid kunye nempompo ayibizi kakhulu.

Inkonzo yethu

I-1.any Imibuzo iya kuphendulwa ngaphakathi kwiiyure eziyi-8 zomsebenzi.

2. UMVUZO WENKQUBO YEMPIMBAL YENKQUBO YOKUGQIBELA, Wamkelekile ukuba utyelele iwebhusayithi yethu (iVenkile ye-Intanethi) kunye nomzi-mveliso.

I-3.Uyilo oluStostom Leyo, i-OEM kunye ne-ODM yamkelekile.

Umgangatho we-4.ight Umgangatho, ixabiso elinengqiqo nenokhuphiswano.

Ixesha le-LCORD, 5-25dys yemveliso ye-bulk

6.Khetha: Simkele ukusetyenziswa kwentlawulo ngu-T / T, L / C kunye neManyani yaseNtshona.

7.Sinelungelo lokusebenzisana okuqinileyo kunye ne-verter, nawe unokukhetha phambili eyakho i-Shund.

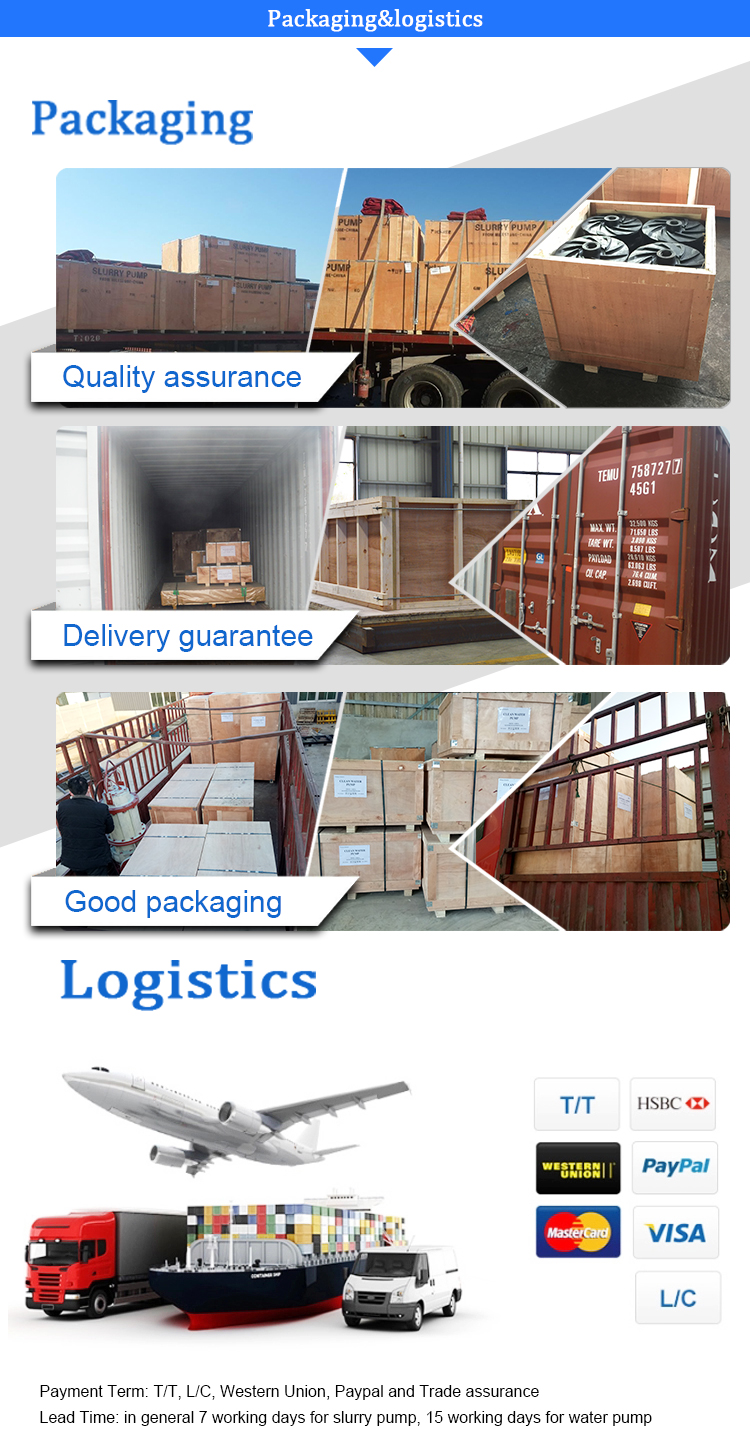

Inkonzo yentengiso ka-8.UThente: Zonke iimpompo zeCenyrifugal ziya kube zisemgangathweni ngokungqongqo kwindlu ngaphambi kokuba zipakishwe. Zonke iimpompo zeCenyrifugal ziya kupakishwa kakuhle njengesicelo ngaphambi kokuthumela.