Impompo ye-TZ

Umgaqo omtsha woyilo:

Iimpawu:

Umgaqo woyilo omtsha woyilo, ujonge kwiimpawu ezahlukeneyo kunye neemfuno zokusetyenziswa okwahlukileyo komthengi kwaye yamkele ulungiselelo olwahlukileyo.

Ukunyanzelwa komsebenzi kufumanisekeke kulungelelwano olunamandla kwaye kunokwanelisa iimfuno ezahlukeneyo zobugcisa.

Intsimi yesicelo:

I-metallgy kunye neyam: Izothutho emnyama kunye ne-Coloped Ikhosi-Igos-I-MAY-MAY NOKUGQIBELA NOKUGQIBELA-MAM, njl njl.

Amandla oMbane: Izothutho e-Ash Mud kunye ne-slirry kumandla oMbane, njl.

I-Coal: ukuthutha ikhosi eyahlukeneyo kunye nodaka oluPhezulu, njl.

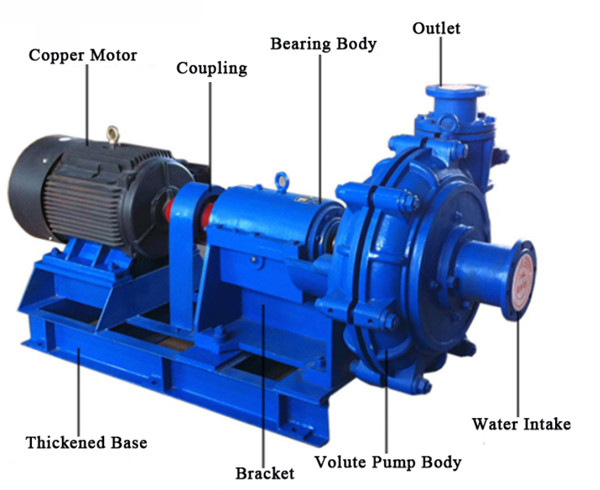

Izixhobo zawo

Ukusetyenziswa kwendlela ye-CFD:

(I-Complecal Flamics fluid), esele isetyenziselwe ukusetyenziswa ngempumeleloUkudalwa kunye nokuYila iimpompo kwinkampani yethu, yindlela entsha ye-brand efakelayoIndlela yekhompyuter yohlalutyo kunye nokubalwa kokusebenza kwe-fluid yendlela.Ngokwemfuno yabathengi kunye neemeko zentsimi zokusetyenziswa kwexesha le-slirry pump,Iingcali zihlalutya kwaye zibale ibala le-fluid yangaphakathi (ifilimu ye-velocity kunye nentsimi yoxinzelelo, njl. Njl.) yohlobo lwe-TZ Pump, chaza ngokusebenza Iiparamitha kwaye emva koko qala ukwenza indlela yokuyila ngokwesiphumo ukuzefezekisa ukuphucula ukusebenza kwabo ngalo lonke ixesha.

Isicelo se-Cae software:

Ukucombulula indleko zokuphosa ngexesha lokuhlangana, ukuphucula ubungakanani be-chatss,Ukunyusa ixesha lethala lemidlalo, inkampani yethu isebenzise i-cae ye-cae callUkuphosa iitekhnoloji ngempumelelo, ukubala kwaye kuhlaziywe intsimi yesantya sokupakisha kwayeIntsimi yobushushu yenkqubo yokuphosa iinxalenye eziphambili, iphoso le-Implay kunye nenkqubo yokukhuphakwaye ngokuchanileyo kwakuqonda ukunqongophala kokuphosa i-shrink ye-shrink, shrink cavity, igesiUkufakwa kunye nokufaka i-slag, ukuze kuphuculwe iitekhnoloji, ukuphelisa ukusilela, okanyeDlulisa ukusilela kwindawo engayi kuphembelela ukusetyenziswa kwabathengikwaye ufezekise ukuphucula ubungakanani bemveliso rhoqo.

Olona hlobo loyilo oluthembekileyo:

Olona uyilo lwemodeli oPhambili lwePump Intloko:

Intloko yempompo inokwahlulwa ibe yinto ezimbini zokwenziwa, impompo enye yempompo kunyeipompo iphindwe kabini, ngokokukhiwa kwayo. Ukwakhiwa komtshato

Impompo yempompo iba neenzuzo zobunzima bokukhanya kunye nobungakanani obuncinci, njl njl.ye-pumps ephindwe kabini kunezibonelelo zokugcina uxinzelelo, kwaye isetyenziselwa

Inqanaba elinye okanye i-insimung uthotho.

Ukunyanzelwa kweempompo zempompo eziphindwe kabini kunokwahlulwa kuhlobo lwe-liner yentsimbi kwayeUhlobo lwerabha (i-nometal) uhlobo lwe-liri-disdisant kunye ne-corrossionant. Ingasetyenziselwa ukuthutha zonke iintlobo ze-abrasive& Slurry. Uhlobo lwe-Lineber Line ilungele ngakumbi ukuthutha ezahlukeneyoIngqolowa iphakathi kwe-abrasion kunye ne-corrosion.

Izinto eziphezulu kunye nobuchule bokunganyangeki:

I-Hydraulic eyamkelweyo yoyilo lwe-hydraulic, inxibe i-abrasion yamalungu empompo inokuphuculwa

ngempumelelo. Ibaluleke kakhulu ebomini bempompo ukuba ukuba izinto ezikhethiweyo zilungele

ulwelo. Ngokweemeko zekhonkrithi ze-rimete yeemeko nganye, silinganiselwe

hlalutyisha nzulu indlela yayo yokunxiba kwaye unxibe imigaqo-nkqubo, ukhetha i-serial efanelekileyo

Umbandela wokunganyangekiyo kunye nokunganyangeki okanye enye into enokunganyangeki yentsimbi ye-nonmetal yokunxiba ukunxiba iinxalenye zokuhamba kancinci ukuze udibanise isicelo sempompo

kunye neenxalenye ezikhethiweyo ukuze zifumane ingeniso ye-Super.

I-Abrasion ye-abrasion iyaxhaswa ngamandla.Umxholo wezinto ezinokudinwa kunye ne-corrossionant ukhethwe ukuba ithutha amanzi ngokomgangatho,Ububanzi bengqolowa, intsebenzo yengqongqo, ubushushu kunye ne-njl. Ziyintoni i-rials antiwearIzinto eziziswayo eziza kuziswa kwaye zaphuhliswa ngokwendlela yokuziqhelanisa.