Izingxenye zamaphampu we-ceramic slurry

Izingxenye ze-Ceramic Slurry Pumps:

I-Impeller iyingxenye esemqoka ejikelezayo evame ukuba nenqola yokudlulisela futhi iqondise amandla we-centrifugal ku-ketshezi.

Impeller evaliwe

Abangenzi bavame ukuvalwa ngenxa yama-effessicoent aphezulu futhi athambekele ekugqokeni esifundeni sangaphambili se-liner.

UFrancis Vane

Ezinye izinzuzo zephrofayili ye-Francis Vane zingukusebenza okuphezulu, ukusebenza okungcono kokudla nokudla okungcono kancane ezinhlotsheni ezithile zezinhlobo ezithile ze-slurry ngoba izeluleko angle to uketshezi zisebenza kahle.

Concave yakhelwe

I-Impeller iyanciphise, ingcindezi ezungeze ama-bhlods izophansi, ngakho-ke izoba nokusebenza okungcono kokugqoka.

Into uqobo lwayo

Izingxenye ezimanzi zenziwe nge-aillicon Carbide ceramic ngokusebenza kwe-sontering, okuzonikeza ukusebenza kwempumputhe ukugqoka nokuqina komzimba, futhi kungamelana nomthelela ophikisayo ngezinhlayiya ezinkulu (<15mm) eSlurry. Yile mpompo yensimbi ye-alloy engenakwenza.

- Gxila Ukungamelana

- Ukumelana nokugqwala

- Isikhathi sokuma

Ngephampu ye-slurry, izingxenye ezimanziKusho izingxenye zokulahla ezithintana nemidiya ye-fluid, imvamisa kubandakanya i-impeller, ipuleti elijikelezayo, isihlahla somphimbo. Izingxenye zizokwenziwa kalula noma zivuswe uma zisebenza futhi ziphindiselwa zonke izikhathi.

Imvamisa izingxenye zamaphampu zenziwe ngensimbi, insimbi, ithusi, ithusi, i-aluminium, ipulasitiki njll. Kepha i-alloy ephezulu ye-chrome ne-elastomer manje sekuyinto ebalulekile yamaphampu we-slurry. Eminyakeni yamuva nje ezinye izinkampani zizama ukwenza izingxenye ezimanzi ngama-ceramics futhi idatha eminingi ivela kuma-labs namagquma akhombisa ukuthi izingxenye ezimanzi zobumba ze-ceramic zingasebenza isikhathi eside kune-aloy ephezulu ye-chrome.

Ngezinto ezibonakalayo ze-Chrome Alloy, uhlobo olujwayelekile luyi-alloy ephezulu ye-chrome (27% CR), ingasetshenziswa kusuka ku-PH 5 kuye ku-12, futhi ubunzima bayo bungaba yi-HRC58, okuyisinqumo esihle kakhulu sokulawulwa okumnandi nokuthutha. Kepha kwezinye izimo, i-PH ingaphansi kuka-5, khona-ke sizama i-BDA49, singasekele ku-PH4, ikakhulukazi esetshenziswa ekusebenzeni kwe-FGD.

I-elastomer isetshenziswa kabanzi ezimweni ezinhle ze-slurry kanye ne-pH ephansi kuya ku-2. Kukhona futhi ama-rubber amaningi ngezimo ezahlukahlukene, njengenjoloba 08, irabha, irabha 55, S02, njll.

Futhi muva nje, i-polyurethane iyathandwa kwezinye izimo. Kuhle ekugqwaneni nasekugqokeni izimo.

Yini eyengeziwe ye-ceramic yephampu ye-slurry ilungile ukufaka esikhundleni ama-lastomers kanye ne-polyurethane esimweni esithile. Ubulukhuni obuphezulu nokugqwala okukhulu kwenza ukuthi kungathatha isikhundla se-metal impeller kwezinye izimo.

Izinto ezibaluleke kakhulu zokumisa i-Ceramic Slurry Pump ukuze ungene esikhundleni ezinye ziyintengo kanye nokushaywa. Kepha ezinye izinkampani zixazulule lezi zinkinga, okusho ukuthi ezinye izinkampani zenze ukuthi ziphumelele ekwenzeni ipompo ye-ceramic slurry engama umthelela wezinhlayiya ku-fluid media kanye nephampu ayibizi kangako.

Inkonzo Yethu

Imibuzo engu-1.Any izophendulwa kungakapheli amahora ayi-8 okusebenza.

Umkhiqizi wepompo wepompo we-2.profusession centrifugal, wamukelekile ukuvakashela iwebhusayithi yethu (i-inthanethi esitolo) kanye nefektri.

I-3.Customized Design iyatholakala, i-OEM ne-ODM yemukelwa.

Ikhwalithi ye-4.Gigh, intengo enengqondo nencintisana.

Isikhathi sokuhola esi-5, 5-25Diays for Bulk Pump Production

6.Fayment: We ngokwejwayelekile yamukela inkokhelo nge-T / T, L / C neNtshonalanga Union.

7.Siba nokubambisana okuqinile nomdluliseli, futhi ungakhetha okwakho ukuthunyelwa.

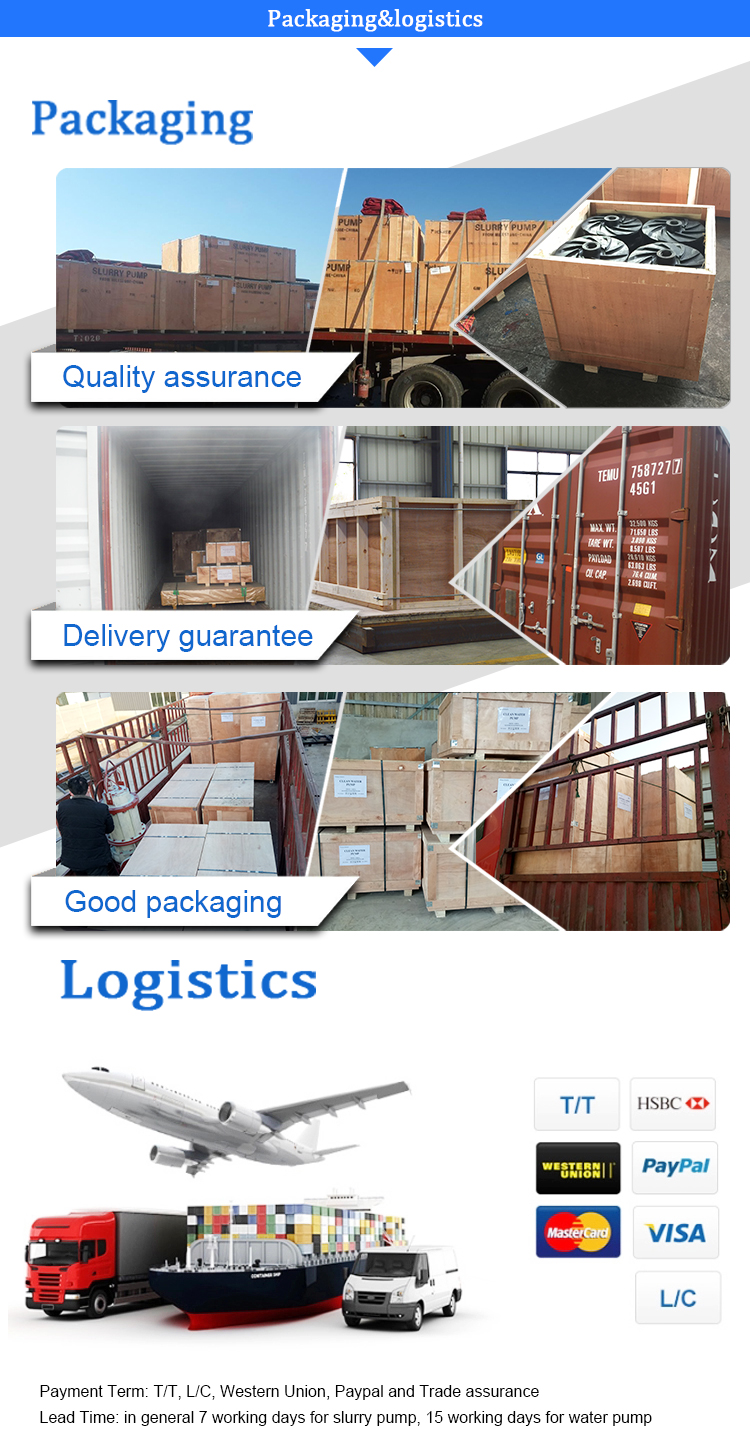

8.After-Sale Service: Wonke amaphampu we-centrifugal azoba yikhwalithi eqinile ehlolwe endlini ngaphambi kokupakisha. Onke amaphampu we-centrifugal azopakishwa kahle njengesicelo ngaphambi kokuthumela.