I-XSR eshisayo yamanzi aqhekezayo

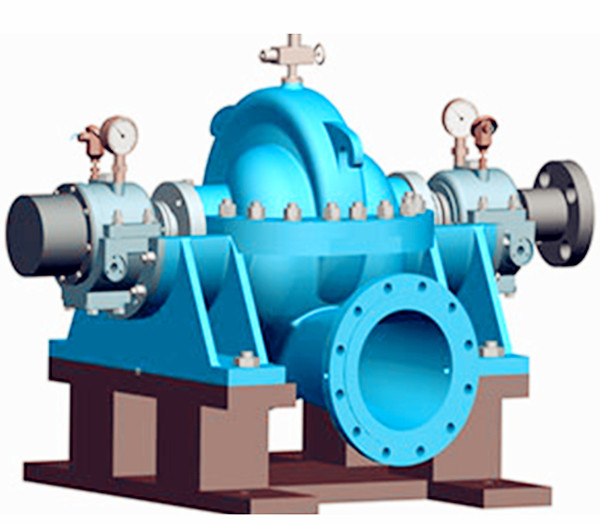

Ukuchaza ngempompo

I-XSR Series Sinye Spreen Suction Suction Suction Pull Pumple Split Case yenzelwe ngokukhethekile ukudlulisa amanzi okujikeleza kunethiwekhi yokushisa yesitshalo samandla afudumele. Iphampu yenethiwekhi yokushisa kamasipala izoshayela ukugeleza kwamanzi njengombuthano kunethiwekhi. Ukujikeleza kwamanzi okugeleza emuva kusuka kwinethiwekhi kamasipala yokushisa kuzokhushulwa yipompo futhi kufuthelwe yi-heater, bese kudluliselwa emuva kunethiwekhi yokushisa kamasipala.

Amapharamitha Wokusebenza Okukhulu

● I-Pump Outlet Ububanzi be-DN: 200 ~ 900mm

● Amandla Q: 500-5000m3 / H

● Ikhanda H: 60-20m

● Ukushisa T: 0 ℃ ~ 200 ℃

● ipharamitha eqinile ≤80mg / l

● Ingcindezi evumelekile ≤4MPA

I-oda elenziwe ngokwezifiso liyatholakala Pull Pump in Heating Network

Incazelo yohlobo lwepompo

Isibonelo: xs R250-600AxSR:

250: I-Pump Outlet Ububanzi

I-600: ububanzi obujwayelekile bokungenisa

A: Kushintshwe ububanzi obungaphandle kwe-impeller (ubukhulu be-max ngaphandle koMark)

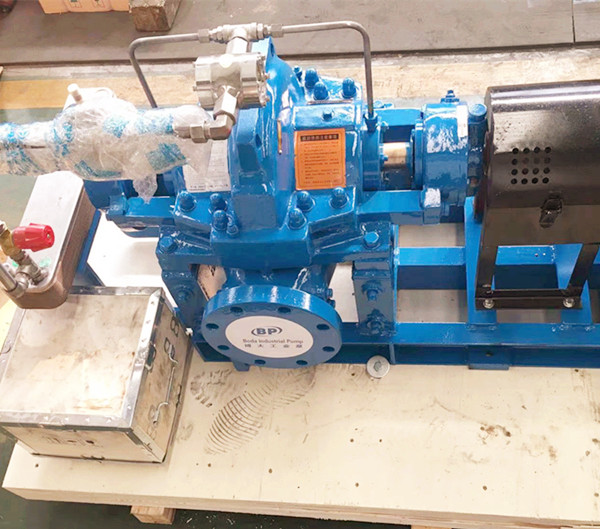

Uhlu olunconyiwe lwezinto ezibonakalayo zezingxenye eziphambili:

I-Casing: qt500-7, ZG230-450, ZG1CR13, ZG06CR199NI10

I-Impeller: ZG230-450, ZG2CR13, ZG06CR199NI10

Shaft: 40Cr, 35CRMO, 42CRMO

SHAFT SLEEVE: 45,2CR13,06CR19NI10

Gqoka Ring: Qt500-7, ZG230-450, Zcusn5pb5zn5

Ukuthwala: SKF, NSK

Isici Sokuhlelwa Kwepompo

1: Thayipha amaphampu we-XSR asebenza ngokusheshe ngomsindo omncane nokudlidliza, ngenxa yokuhlukaniswa okufushane phakathi kokuxhaswa zombili eziseceleni.

2: I-rotor efanayo yamaphampu we-XSR amaphampu angasebenza ngokuqondisa kabusha ukugwema ukulimala kwamaphampu ngesando samanzi.

3): Idizayini eyingqayizivele yefomu lokushisa eliphakeme: Amanzi apholile angaphandle azotholakala selokhu kwavuthwa ngegumbi elipholile; Ukugcotshwa kungagcotshwa ngamafutha noma amafutha, uma isiza sinamanzi afanayo angaphandle angenayo njengamaphampu okuhambisa, kanti ingcindezi ingu-1-2 cm2 ephakeme kunengcindezi yokungena kwepumpu, kuyilapho amanzi okugeza okwenziwe ngomshini angaba khona exhunywe ngezimo ezingenhla azitholakali, sicela ulandele imiyalo elandelayo: ukupholisa nokuhlunga okushisa okushisa okushisa okuvela ekuphumeni kwamaphampu okuthi kusuka ekuphumeni kwamaphampu kuFush izilonda ezisebenza ngomshini, ezingenza ukuthi imishini yemishini igxile futhi ibekezeleleke; Isikhombisi samanzi kufanele silungiswe ohlelweni lwamanzi acwebezelayo, olungakwazi ukuqapha amanzi axakile futhi lushintshe ukugeleza kwamanzi nengcindezi (imvamisa ingcindezi kufanele ibe ngu-1-2kg / cm2 ephakeme kunengcindezi yokungena kwepumpu); I-Bimetal thermometer kufanele ihlanganiswe ngemuva kwe-heater enshisper, kanye nedivayisi ethukuthele ngokuzithandela, engabheka ngenkathi izinga lokushisa lidlula umkhawulo; Futhi ukushintshwa kwengcindezi ehlukile bekungakhethwa, obekubhekisisa i-heater eburn. Ngaphezulu komklamo oyingqayizivele kwenza iphampu ingasebenza ezimweni zokushisa eziphakeme eziseduze kwama-centigrade angama-200

4: Idivaysi yokutholwa kwejubane elihlanganiswe nensimbi yokulinganisa isivinini futhi i-probe izolungiswa endaweni yokwengeza shaft uma iphampu iqhutshwa imvamisa eguquguqukayo noma i-turbine ye-turbine; I-Othe1Wea1We izolungiswa kudivayisi yokuhlangana uma iphampu iqhutshwa ngemoto ejwayelekile ngokuhlangana kwe-hydraulic.

5: Thayipha amaphampu we-XSR angaba mpo noma ngokuqondile okhutshwe ngokulandelana ngokwesimo sokusebenza esihlukile, onophawu oluphezulu lokupakisha lokushisa noma uphawu lwemishini; Ungasebenzisa futhi izilo ze-cartridge, ngakho-ke kulula kakhulu futhi kulula ukuzifaka esikhundleni sazo.

I-6: Ngomklamo wezimboni, uhlaka lwe-XSR lucacile futhi luhle ngokuhambisana nama-aesthetics wanamuhla.

7: Ukusebenza kahle kwamaphampu we-XSR kungama-2% -3% aphakeme kunamaphampu wohlobo olufanayo ngenxa yokwamukela imodeli ye-hydraulic ethuthukile futhi ngaleyo ndlela anciphise izindleko ezisebenzayo kakhulu.

I-8: Ukukhetha ukuthwala imikhiqizo yokungenisa, nezinye izinto ezikhethiwe yikhasimende, yenza ipompo ifanele

nganoma yisiphi isimo sokusebenza futhi unciphise izindleko zokulungisa.

9: Kuyashesha futhi kulula ukuhlanganisa nokunciphisa izingxenye ze-rotor ngenxa yokusebenzisa i-ethress ukuhlanganisa ukuhlanganisa.

10: Akunasidingo ukwenza ukulungiswa kunoma yikuphi ukucaphuna lapho kuhlangana.

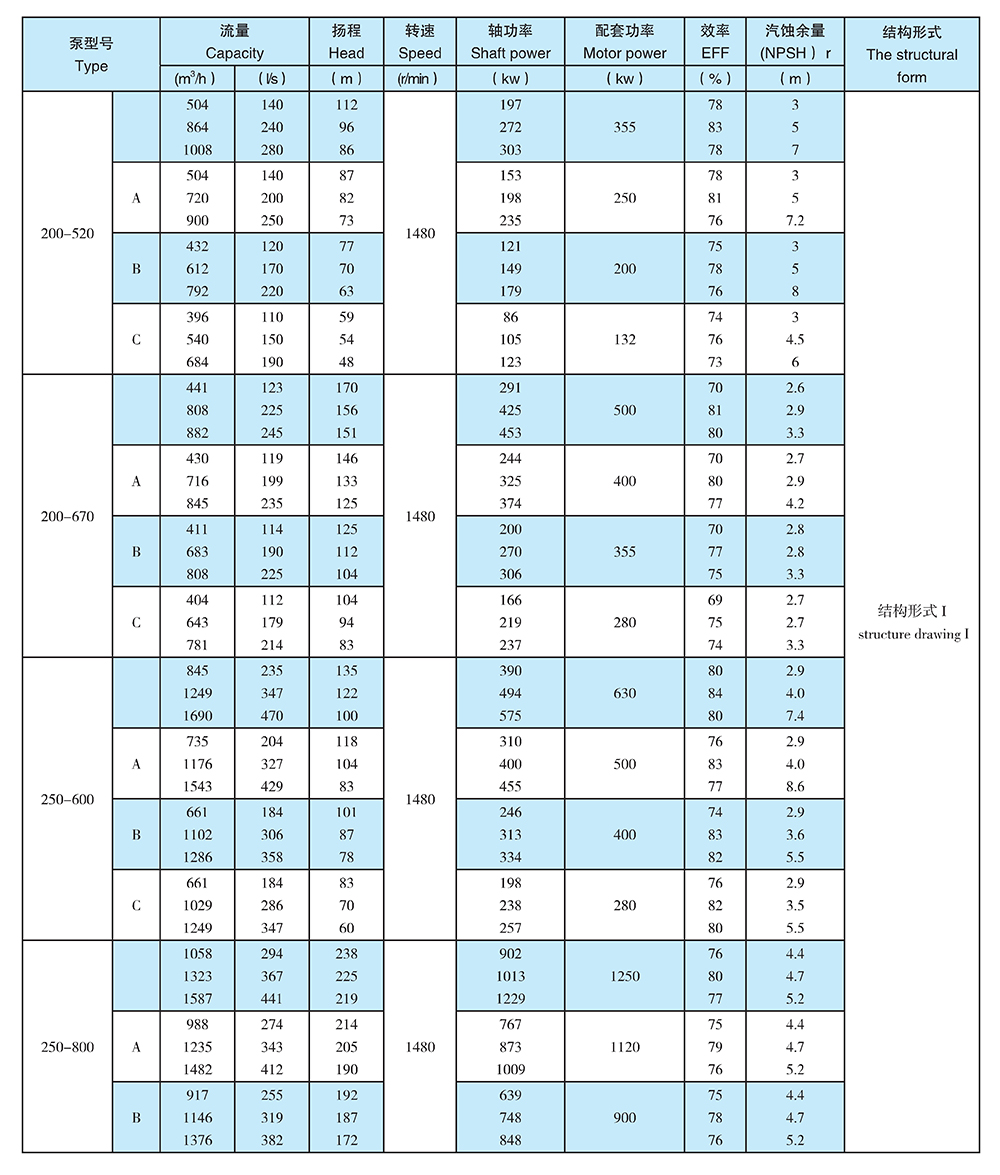

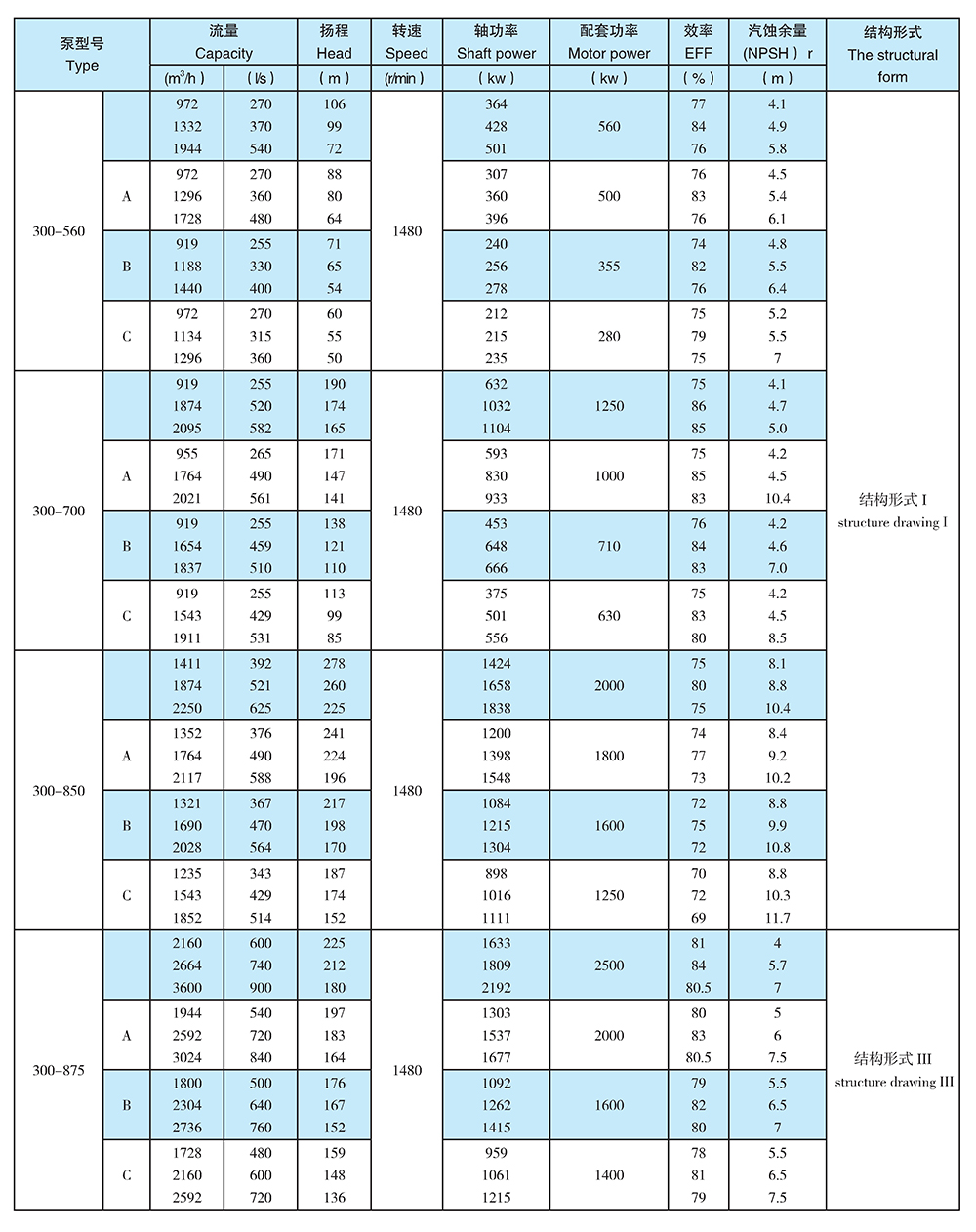

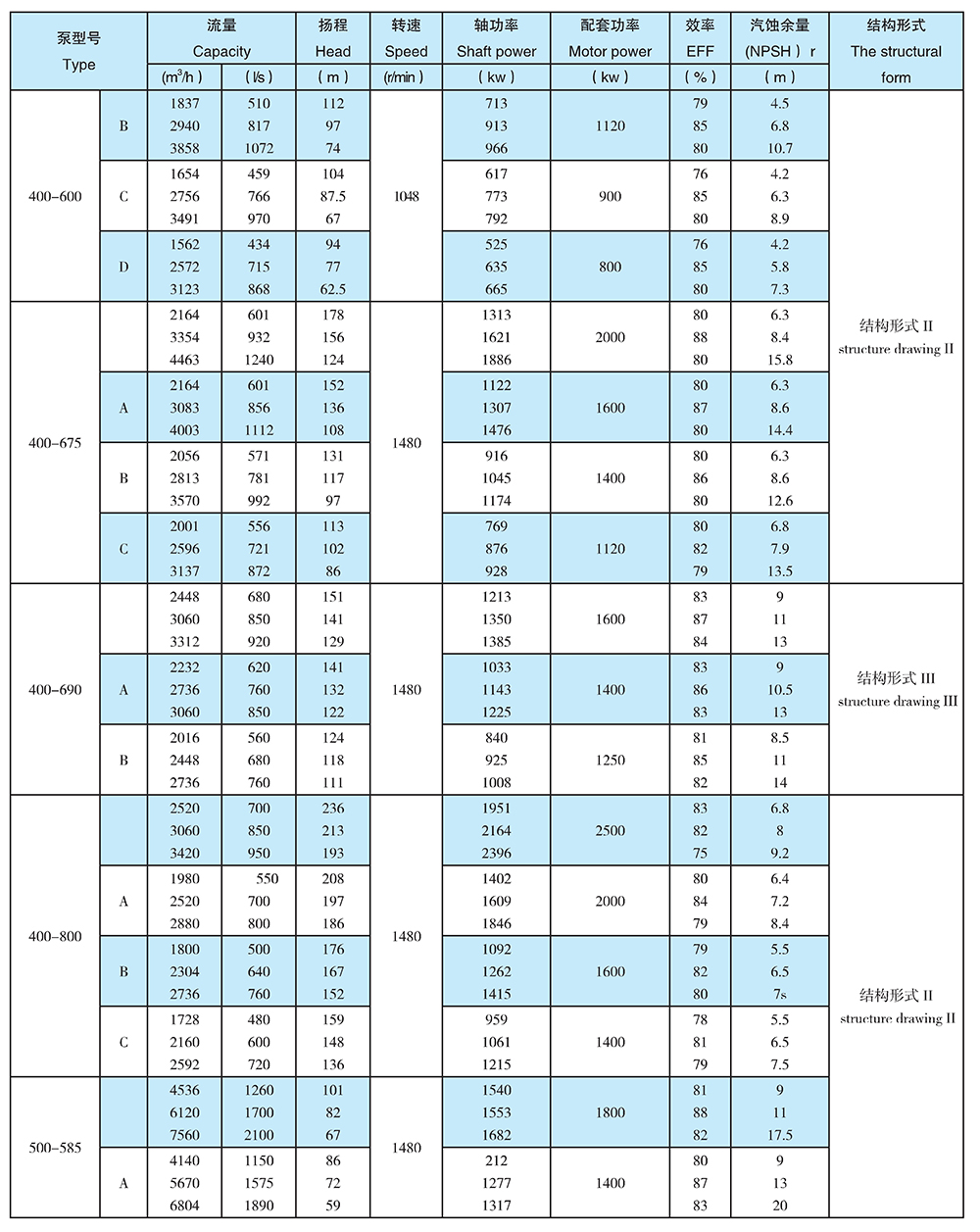

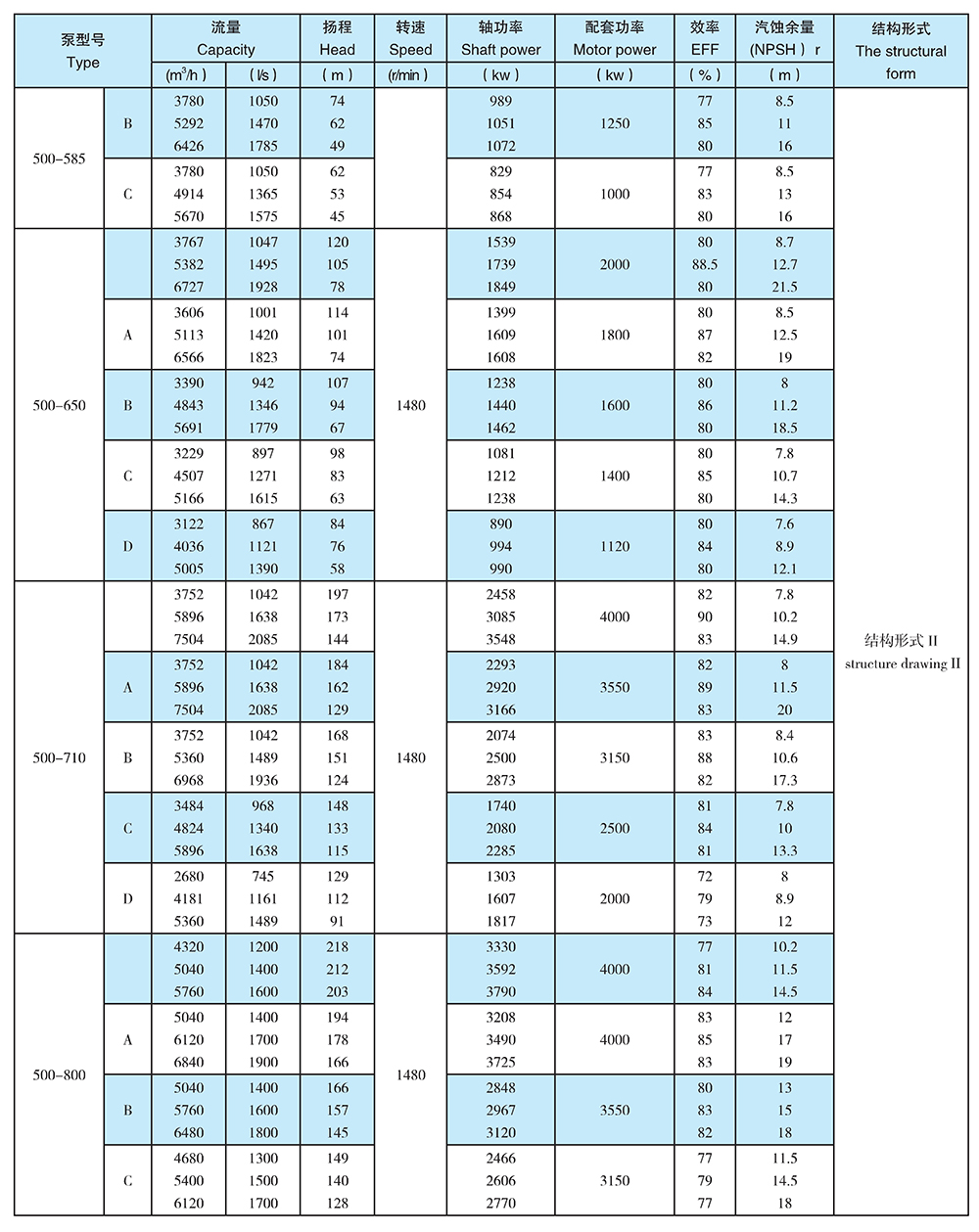

Mpompo Idatha yezobuchwepheshe