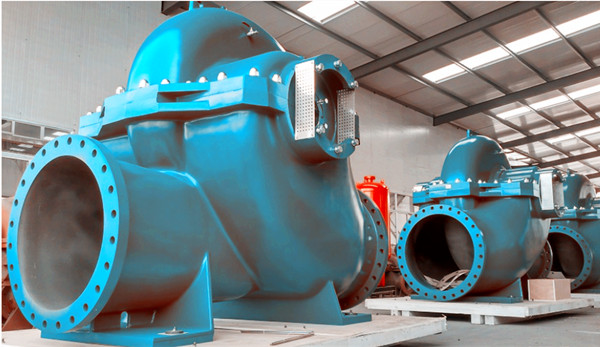

I-XS Split Case Pump

Incazelo yePump:

I-XS Type Pump yisizukulwane esisha sokusebenza okuphezulu okuphezulu kwe-centrifugal split split. Zisetshenziselwa ikakhulukazi ukuletha uketshezi lwesitshalo samanzi, ukujikeleza kwamanzi okusakazwayo, uhlelo lokushisa ipayipi, ukuhanjiswa kwamanzi, ukuchelela kanye nohlelo lwamanzi, uhlelo lokuhlinzekwa kwamanzi kwezimboni, ukuvikelwa komlilo, imboni yezokuvikela, ukuvikelwa komlilo, imboni yezokuvikela, ukuvikelwa komlilo, imboni yezokuvikela, ukuvikelwa komlilo, imboni yezokuvikela, ukuvikelwa komlilo, imboni yezokuvikela, ukuvikelwa komlilo, imboni yezokuvikela, ukuvikela umlilo kanye neyami. Kuyinto entsha ye-SH, S, SA, SLA ne-SAP.

| Amapharamitha Wokusebenza Okukhulu● I-Pump Outlet Ububanzi be-DN: 80 ~ 900mm● Amandla Q: 22 ~ 16236m3 / h● Ikhanda H: 7 ~ 300m ● Ukushisa T: -20 ℃ ~ 200 ℃ ● ipharamitha eqinile ≤80mg / l ● Ingcindezi evumelekile ≤5mpa

| Incazelo yohlobo lwepompo● Isibonelo: I-XS 250-450A-L (R) -J● I-XS: Uhlobo oluthuthukisiwe lwe-centrifugal splifugal● 250: I-Pump Outlet Ububanzi ● 450: Ububanzi obujwayelekile bokungenisa ● A: Kushintshwe ububanzi obungaphandle kwe-impeller (ubukhulu be-max ngaphandle koMark) ● l: Intaba mpo ● R: Amanzi okushisa ● J: Ijubane lepompo lishintshile (gcina ijubane ngaphandle koMarku) |

Uhlelo Lokuxhaswa Kwepompo

|

Into yendaba | Uhlelo lokuxhaswa lwempompo a | Uhlelo lokuxhaswa lwempompo Q | Uhlelo lokuxhaswa lwempompo b | Ipompo yokusekela uhlelo s | |||

| 1 | 2 | 1 | 2 | + | |||

|

Ukugoqa amaphampu | I-grey cast iron | I-Ductile cast Iron | I-Ductile cast Iron | Extraw carbon stainless insimbi engagqwali | I-Iron ye-NI-CR ChromiumCast | I-Ductile cast Iron | Insimbi engagqwali |

| Umngenzi | Insimbi empunga | -Bili insimbi | Insimbi engagqwali | I-Duplex SS | Tin Bronze | Tin Bronze | Tin Bronze |

| Umgodi | # 45 insimbi | # 45 insimbi | Insimbi engagqwali | I-Duplex SS | I-2CRL3 | I-2CRL3 | I-2CRL3 |

| SHAFT SLEEEVE | # 45 insimbi | # 45 insimbi | Insimbi engagqwali | Extraw carbon stainless insimbi engagqwali | LCRL8NI9TI | LCRL8NI9TI | LCRL8NI9TI |

| Gqoka indandatho | Insimbi empunga | -Bili insimbi | -Bili insimbi | I-Duplex SS | Tin Bronze | Tin Bronze | Tin Bronze |

| Amasethingi | Amanzi ahlanzekile nezinhlelo zamandla eziphansi | Ngezinhlelo zokusebenza ezihlanzekile zamandla aphezulu | Ngemidiya enokungcola okuqinile kokungcola okuqinile | Ipompo yamanzi olwandle | |||

| Lokhu kucushwa kunconywa ngumenzi, amakhasimende angashintsha izinto zawo ngokuya ngezidingo ezithile. | |||||||

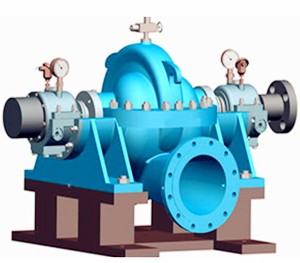

Ukudweba umdwebo i

Umdwebo wokwakha II

Isakhiwo se-XS-L vertical

Isici Sokuhlela

⒈ Thayipha amaphampu we-XS asebenza ngokuqinile ngomsindo omncane nokudlidliza, angasebenza kahle ekukhuliseni isivinini ngenxa yokuxhaswa okufushane phakathi kwazo zombili izikhala eziseceleni, ngakho-ke zingasetshenziswa kabanzi.

⒉ Ukuhlelwa kwamapayipi kohlobo lwe-XS Pump kubukeka kulula futhi kuhle ngenxa ye-inlet nokuphuma kulayini ofanayo.

⒊ I-rotor efanayo yamaphampu we-XS ama-XS ingasebenza ngokuqondiswa kabusha ukuze igweme ukulimala kwamaphampu ngesando samanzi.

Idizayini eyingqayizivele yefomu eliphakeme lokushisa: Ukusebenzisa ukwesekwa okuphakathi, ukusebenzisa i-casing yepompo, usebenzisa izimpawu zokupholisa nokuthwala okuvuthayo kwamafutha, yenza i-XS pump efanelekile ukusebenza ngo-200 ℃, ikakhulukazi ngokufaka uhlelo lokushisa inetha.

I-5

6. Ngomklamo wezimboni, uhlaka lwe-XS lucacile futhi luhle ngokuhambisana nama-aesthetics wanamuhla.

7

8. I-NPSHR yamaphampu we-XS ama-XS angamamitha ayi-1-3 aphansi kunamaphampu wokuhlukanisa afanayo anciphise izindleko zesisekelo futhi anwebe ukusetshenziswa kwempilo.

9. Ukukhetha ukuthwala imikhiqizo yokungenisa, nezinye izinto ezikhethiwe yikhasimende, yenza ipompo ilungele noma yisiphi isimo sokusebenza futhi inciphise izindleko zokulungisa kakhulu.

10. Akudingekile ukulungisa izimpawu zemishini, ngakho-ke kulula kakhulu futhi kulula ukuzifaka esikhundleni sazo.

11. Kushesha futhi kulula ukuhlanganisa nokunciphisa izingxenye ze-rotor ngenxa yokusebenzisa i-elastic prestress ukuhlangana.

12. Akunasidingo ukwenza ukulungiswa kunoma yikuphi ukucaphuna lapho kuhlangana.

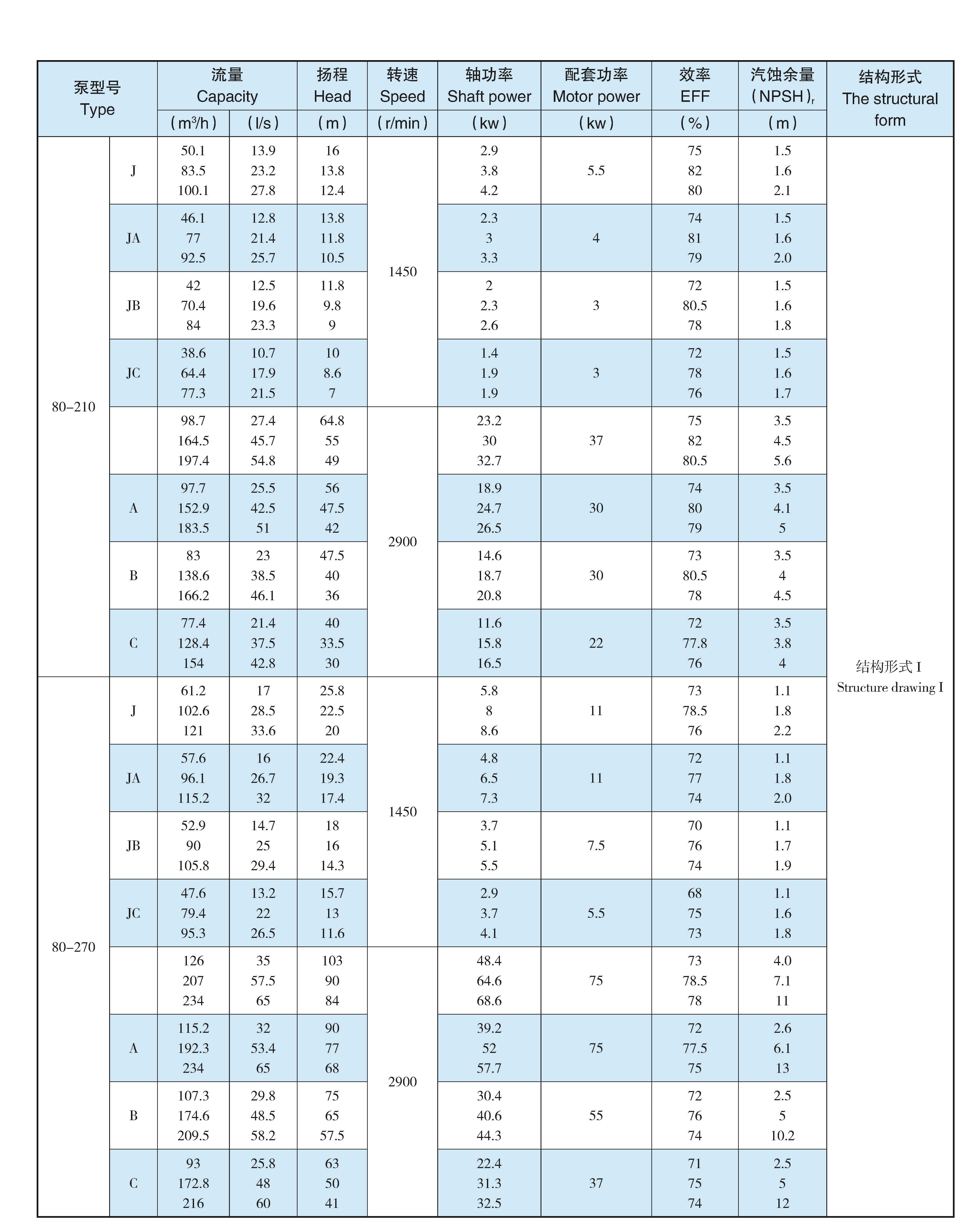

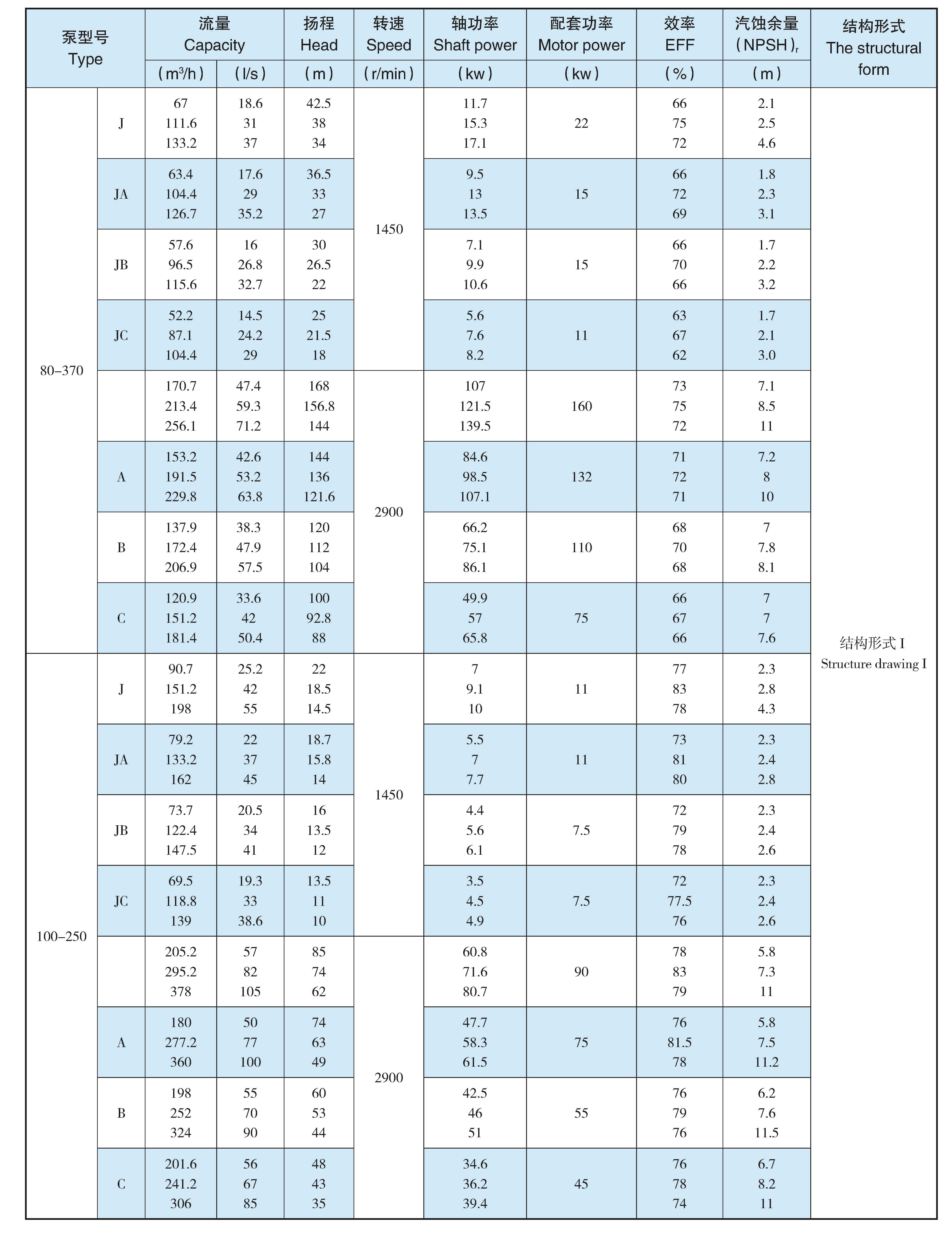

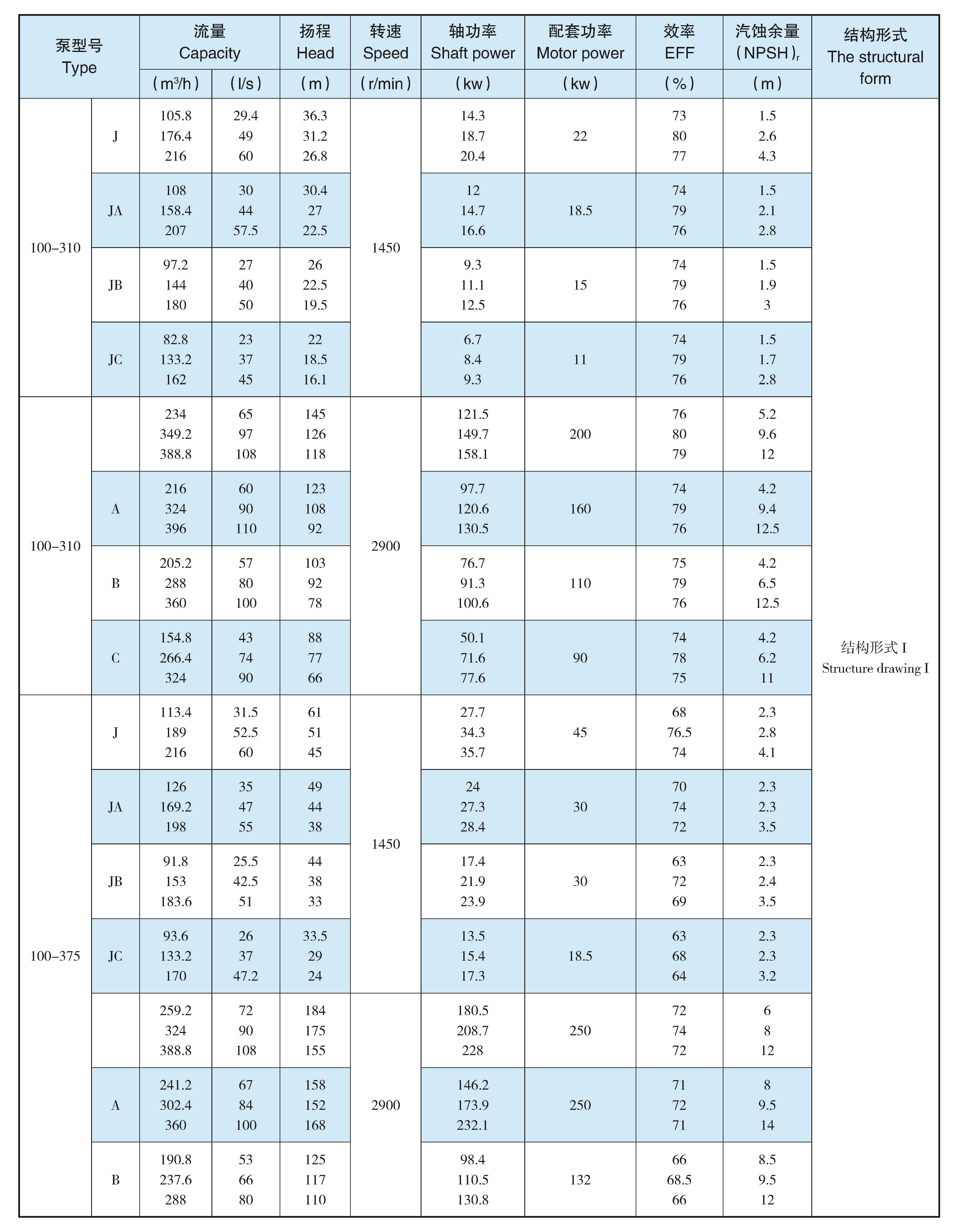

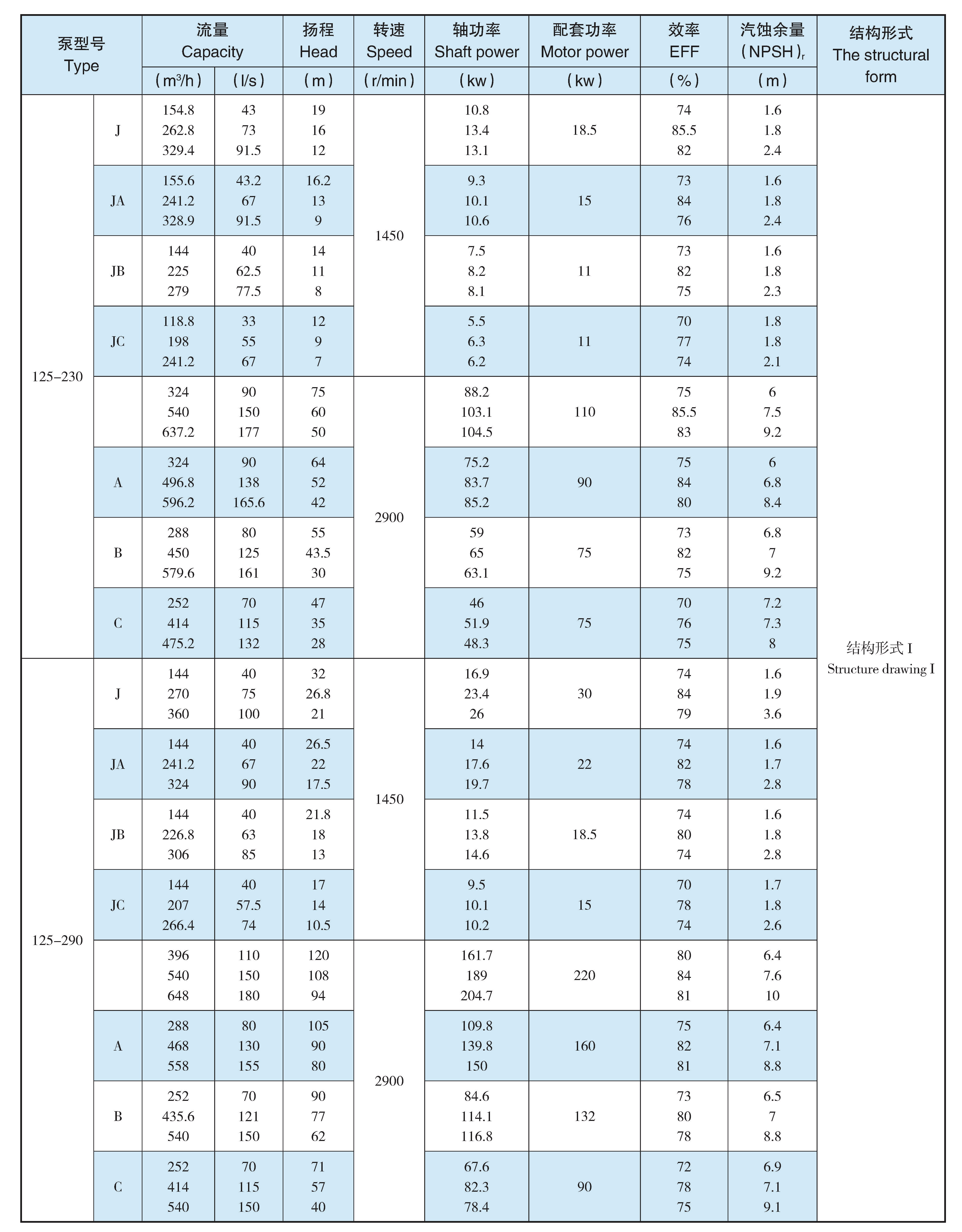

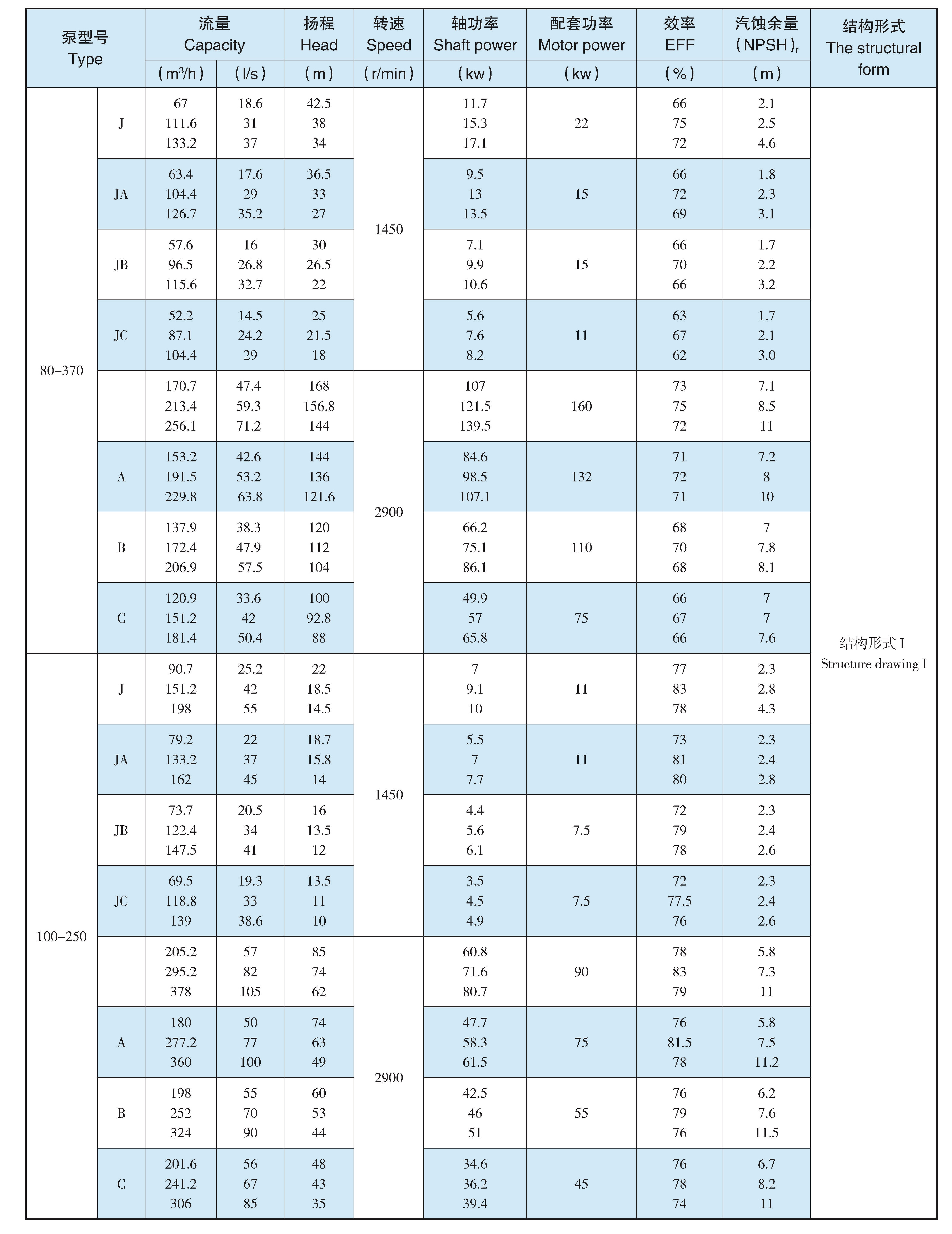

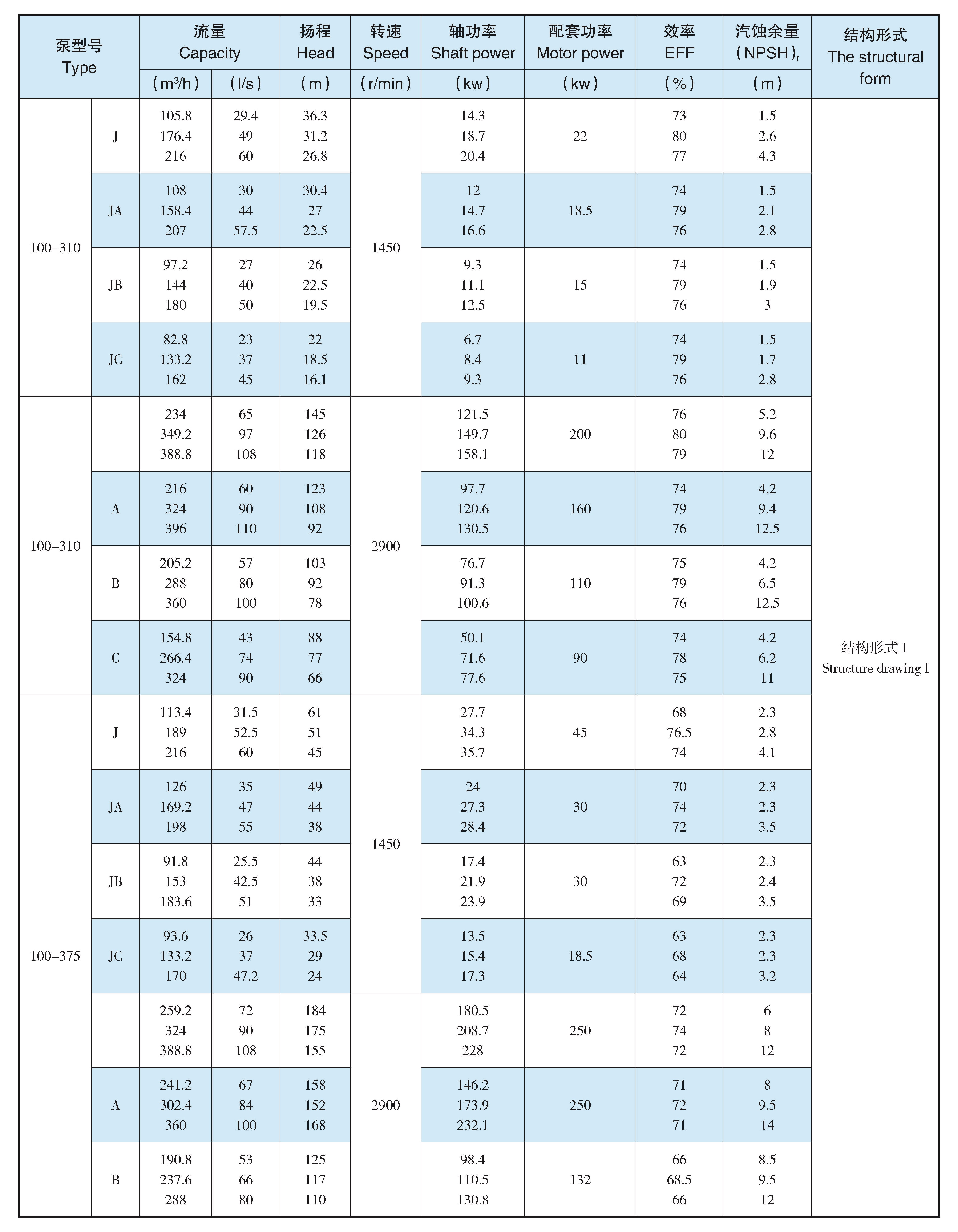

Mpompo Idatha yezobuchwepheshe