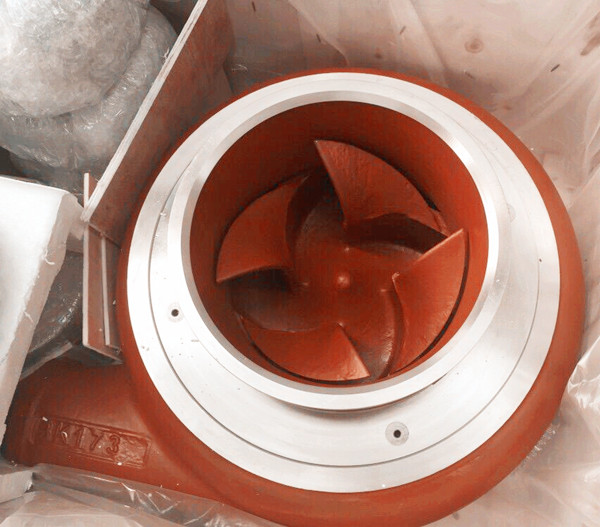

I-Slurry Pup Volute Liner

Boda slurry pump i-volute liner iyashintshana ngokuphelele

1. BDA05iyinsimbi emhlophe engamelana ne-gress enikeza ukusebenza okuhle kakhulu ngaphansi kwezimo ezikhuphelisayo. I-alloy ingasetshenziswa ngempumelelo ezinhlotsheni eziningi ze-slurry. Ukumelana nokugqokwa okuphezulu kwe-Alloy BDA05 kunikezwa ukuba khona kwe-carbides enzima ngaphakathi kwesakhiwo sayo esincane. I-Alloy BDA05 ilungele izinhlelo zokusebenza lapho ukumelana nokugqwala okulindayo, kanye nokumelana nokuguguleka kudingeka.

2. BDA07I-Marten-Sic white iron ngokumelana nokuguguleka okulinganiselayo.

3.bda49Ilungele imisebenzi ephansi ye-PH Corries, lapho ukugqokwa kwe-erosive nakho kuyinkinga. I-alloy ilungele ikakhulukazi

I-Flue gesi Deserulphu-Rization (FGD) nezinye izinhlelo ezilonakalisayo, lapho i-PH ingaphansi kuka-4.

Izingxenye ze-Slurry Poom Main:

• Imper- I-Front kanye ne-Resear Shrouds inezimpunga eziphumayo ezinciphisa ukuphinda zingcolise kanye nokufakelwa uphawu.

I-Hard Metal Nempled Exberlers embi iphelele iyashintshana. I-Cast in Thread Threads ayidingi ukufakwa noma amantongomane. Ukusebenza kahle okuphezulu nemiklamo ephakeme ephakeme iyatholakala.

• ama-liners- Ama-liners angena kalula aphenyiswa, awafakwanga, ku-Casing ukuze anamathiselwe kahle kanye nokunakekelwa kokulungiswa. Ama-hard metal liners aguquguquka ngokuphelele nama-elastomers abunjiwe. I-elastomer

Seal ikhala emuva wonke amalunga we-liner.

• I-Throat Bush -Ukugqokwa kuncishisiwe futhi ukunakekelwa okwenziwe lula ukusetshenziswa kwe-tapered mating peape ukuvumela ukuqondanisa okuhle ngesikhathi sokubuyisana nokususwa okulula.

• Ukuthwala umhlangano -I-shaft enkulu enobubanzi enesifushane i-overhang firection futhi inomthelela empilweni ende evuthayo. Kune kuphela ngama-bolts kuphela adingekayo ukubamba uhlobo lwe-cartridge getry kufreyimu.

Izingxenye ze-Slurry Pumps

Izingxenye zokuphela ze-Slurry Pump Wet ikakhulukazi zifaka phakathi i-Impeller, i-Volute Liner, i-Case, Shaft, ipuleti, isembozo, isembozo sepuleti, i-Shaft Sleeve, ikhava yeplate liner, uhlaka lweplate liner, uhlaka lweplate liner, uhlaka lweplate liner, uhlaka lweplate liner ..

I-1.Centrifugal Slurry Pumps nezingxenye ezisele zingashintshana ngokugcwele nomkhiqizo odumile emhlabeni.

Amaphampu alolokwakhiwa okusindayo, enzelwe ukupompa okuqhubekayo kokuncipha okuxakayo futhi okulimazayo.

I-3. Babonisa ukukhetha okubanzi kwe-abranos metal metal noma i-elastomer elastomer elastomer elastomer ephonsa ama-liners nabangenzi abangenakuguqulwa, konke okuguqukayo ngaphakathi komhlangano ojwayelekile wokuphonsa.

I-4.Wear -Resistant Metal Liner neRubber Liner etholakalayo

Uhlobo lwe-5.Seal: I-Gland Seal, I-Impoller Seal kanye nophawu lwemishini

I-6.Can ifakwe ochungechungeni oluningi

7.Ekulungiswa ekunakekelweni

Izakhiwo zezinto zenjoloba:

Sinezinto ezahlukahlukene zenjoloba zemvelo kanye nama-elastomers, angasetshenziselwa ukupompa ukuwohloka noma ukuncipha kwe-acid. Kepha impahla yerabha ayilungele ama-slurries aqukethe ama-solid abukhali.

Lapho ama-slurres aqukethe izinhlayiya ezinhle, izinto zenjoloba zibonisa ukusebenza okuhle kokugqokwa okungafani.

Izakhiwo zensimbi emhlophe ye-chrome high

Sinezinhlobonhlobo zensimbi ephezulu ye-chrome emhlophe, futhi okuqukethwe kwe-chrome kwehlukile.

Banganikeza ukusebenza okuhle kakhulu ngaphansi kwezimo ezikhuphelisayo. I-alloy ingasetshenziswa ngempumelelo ezinhlotsheni eziningi ze-slurry. Ukumelana nokugqokwa okuphezulu kwe-alloy kuhlinzekwa ngokuba khona kwe-carbides enzima ngaphakathi kwesayensi yalo. Enye indawo ekhethekile ye-Chrome Alloy nayo ilungele ukusetshenziswa lapho ukumelana nokuqina, kanye nokumelana nokuguguleka kuyadingeka.

Insizakalo ye-OEM

Ngokusekelwe eminyakeni eminingi yesipiliyoni esicebile ekukhiqizeni i-Slurry Pumps and Design, iBoda ingenza ngokwezifiso ngokwakho kwesethi yephampu nezingxenye ezahlukahlukene. Izingxenye ze-Slurry Pumpery zenziwe ngezinto ezahlukahlukene ngokuya ngesidingo sekhasimende, njenge: Alloy 20, Hastelloy Alloy, a (6 1) njalonjalo.

Inkampani yethu yenza ukwakheka, ukucubungula kanye nokuguqulwa kwezingxenye ezahlukahlukene zamaphampu ezikhethekile. Ngokusho kwezidingo zomsebenzisi, ifektri ye-boda ingakha izinto ezahlukahlukene kanye nezinto zokuhlangabezana nezidingo zezimo ezihlukile zokusebenza. Noma ngokuya ngezidingo zomsebenzisi ezinguquko ezikhona zobuchwepheshe bemishini, ezihlanganiswe nemodeli yenkampani yethu ecebile, ngokusebenzisa ubuchwepheshe obuthuthukisiwe be-computer Simulation, ukuhlinzeka abasebenzisi ngesisombululo esiphelele nesisebenzayo.

Isicelo:

Lezi zingxenye zisetshenziswa kabanzi kuzinhlelo zokusebenza eziphambili: Isihlabathi esinamandla sokusebenza kwamaminerali nesishisi se-Frevel Coal Prep Feeds agcurate ukucubungula amakhemikhali amakhemikhali wokugaya amakhemikhali ama-pulping celting service amakhemikhali wokugaya amakhemikhali ukucubungula amakhemikhali wokugaya izimboni kanye nokuhlaselwa kwepayipi eliphakeme lokuhamba nge-hydraulic transport ash Icubungula i-sludge eqhumayo emfuleni we-Metal Smilelting River kanye ne-Pond Dred Ukususwa Kwemfucumfucuko Ezinhlayiyani ezinkulu noma eziphansi ze-NPSHA) I-Steel Palm Suger Chege Chege Chege Chemical Power FGD Frac isihlabathi eshaya indle yokwakha indle yokwakha njll.