I-BTL / BDTL Series Slurry ukujikeleza kwe-Slurry

Ukuchazwa Komkhiqizo:

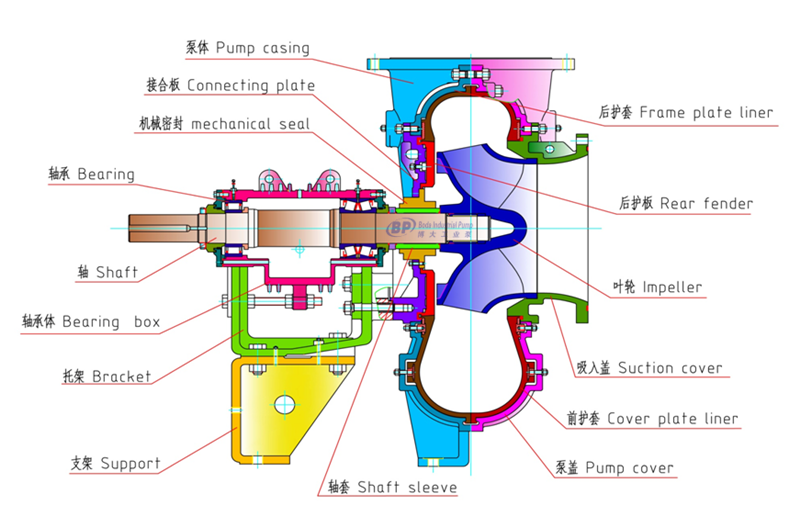

1) Impompo ekhawulela izingxenye zamukela ubuchwepheshe bokuhamba okuthuthukile kokulingisa ukuqinisekisa okuthembekileUmklamo wepompo nokusebenza kahle okusebenzayo.

2) I-anticorrosion & nensimbi yensimbi kanye nezinto zokwakha irabha ezithuthukiswe ngokuqondile i-FGDAmaphampu afakazelwe ngumkhuba wokuthi, angaqinisekisa ukusebenza kwephampu ye-LongLife.Ngokulungisa izingxenye zokuthwala ukushintsha isikhundla se-impeller egumbini lokupompaUkusebenza okuthe xaxa kwephampu kungatholakala. Ipompo ibonakala ngemuvaIsakhiwo se-knock-Down esilula futhi esithuthukile.

I-3) Kulula ukuyigcina futhi ilungiswe futhi idinga ukukhishwa kwamapayipi kanye nokuphuma kwamapayipi amanzi.I-mechanical mechical seal esetshenziswa ngokukhethekile inqubo yokususelwa ekusukeni yamukelwa futhiUkusebenza kwayo kuthembekile.

Ukukhetha okubonakalayo:

Sithuthukise uhlobo olusha lwezinto ezikhethekile ezinemininingwane yensimbi engabi nalutho yokulwa nensimbi yensimbi engenacala kanye nempahla ephezulu ye-chrome emhlophe yensimbi enqubweni ye-FGD.

E-Cubber Pumps Casing, i-Impeller, ikhava yokucaphuna / ikhava yekhava konke okwenziwe ngezinto ezikhethekile zokulwa nokulwa nokulwa nokubhala: impahla ye-back liner Insert irabha lemvelo elinendawo yokulwa nokuwohloka.

E-Metal Pumpel Casing, i-Impeller, i-lineller evuthayo, ipuleti yokumunca kanye nepuleti emuva konke kwenziwa ngezinto ezikhethekile zokulwa nokulwa nokuwohloka, isembozo sensimbi esenziwe ngensimbi enjoloba.

Isici Sokuhlela:

1) Izingxenye zokugeleza kwamaphampu zenzelwe amasu athuthukile we-CFD awenzayo ukuwenza ukuze aqinisekise ukuklanywa kwalo okuthembekile nokusebenza kwayo.

2) Ingashintsha isikhundla se-impeller ekuhambeni kwephampu ngokulungisa umhlangano othwala ukuze impompo isebenza kahle ngaso sonke isikhathi.

3) Lolu hlobo lwephampu lumamukela ukwakhiwa okukhipha emuva, ukugcina ukwakhiwa kwalo okulula nokulungiswa okulula. Akudingi i-disasqwemb inlet & outlet Pipeline.

4) Amasethi amabili e-taper roller bezala ahlelwe ekugcineni kwepompo, i-columl roller ephethe ifakwe emaphethelweni okushayela.

I-5) I-Mechan Seal i-adpotated ihlanganisa ukubekwa uphawu kwemishini okukhethekile kubuchwepheshe be-FGD ukuqinisekisa ukusebenza kwayo.

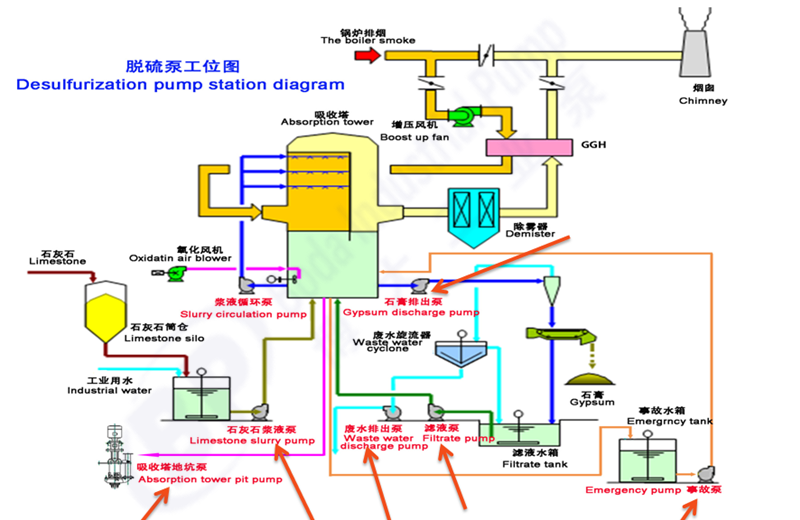

Izicelo:

Zisetshenziselwa ikakhulukazi ukuphatha ama-slurry ngentuthu embhoshongweni wokutholwa kwesiteshi samandla kagesi,lelo yi-Thermal Power Plant FGD (i-Flue gesi Defelfururization).

Isakhiwo sePump:

Ishadi lokukhetha:

Idatha yezobuchwepheshe:

| Isifanekiso | Okukhiqiza Q (M3 / H) | Ikhanda H (m) | Isivinini (r / min) | I-EFF. (%Isihlehlukene | Npshr (m) |

| BDTL400 | 1800-2800-3400 | 13-28-35 | 400-740 | 78-82 | 5 |

| BDTL450 | 2900-3600-4500 | 15-25-35 | 480-740 | I-80-84 | 5 |

| BDTL500 | 3400-4250-5400 | 16-28-32 | 350-590 | 80-85 | 5.2 |

| BDTL600 | 4000-5300-6300 | 15-25-28 | 350-590 | 83-87 | I- |

| BDTL700 | I-6000-7200-9000 | 15-25-30 | 425-590 | 83-87 | 6 |

| BDTL800 | 7450-10000-12000 | 15-24-30 | 425-590 | 83-87 | 7 |

| BDTL900 | I-8400-12000-15000 | 12-21-25 | 400-460 | 84-89 | 7.2 |

| BDTL1000 | 9800-14000-18000 | 15-23-25 | I-360-400 | 83-87 | 7.0 |