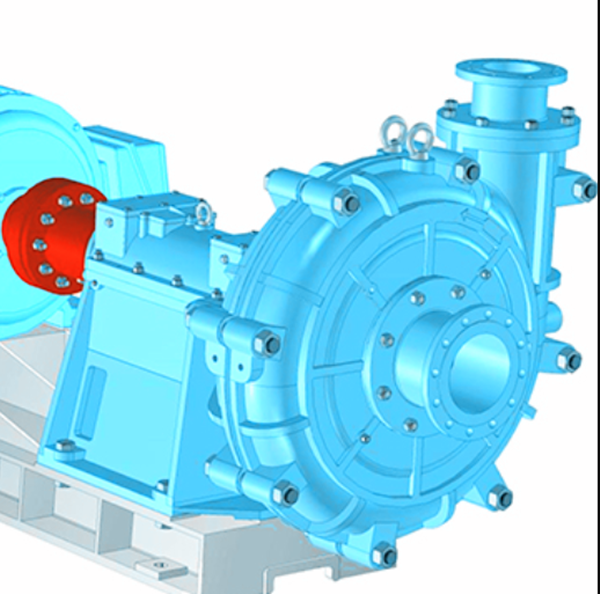

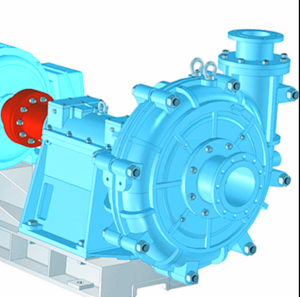

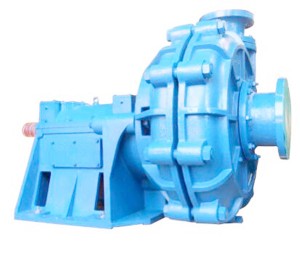

Thayipha i-ZGB (P) I-Slurry Pump

Isingeniso somsebenzi:

1. Ukusebenza okuthuthukile kwe-hydraulic, ukwakheka kwesimanjemanje, ukusebenza okuphezulu kanye nezinga eliphansi le-abrasion2. Indima ebanzi, ukungabongi nokusebenza okuhle kwe-NPSH.3. I-Defeller Seal ehlanganiswe nophawu lokupakisha kanye nophawu lwemishini selusunguliwe ukuqinisekisa ukunqwabelana kusuka ukuvuza.4. Idizayini yokwethenjwa iqinisekisa i-MTBF ende (isikhathi esisho phakathi kwemicimbi)I-5

6.Izinto ezimanzi zezingxenye ezimanzi zazinokusebenza kahle kokugunda nokulwa nokuwohloka, iphampu lingasetshenziselwa ukususa amanzi asolwandle ukuze likuvimbele ekugqekezweni kweSweater, usawoti kanye nenkungu, kanye nokugqwala kwe-electrochemical.

7.Impompo ingasebenza ngochungechunge olunama-multi-esiteji ngaphakathi kwengcindezi evunyelwe. Ingcindezi ephezulu yokusebenza evunyelwe yi-3.6 MPA.

Uchungechunge lwePump lunenzuzo yokwakhiwa okunengqondo, ukusebenza kahle okuphezulu, ukusebenza okuthembekile nokunakekelwa okulula. Ingasetshenziswa kabanzi ngokuphatha inhlanganisela equkethe ama-solids angenayo amandla kagesi, i-metallurgy, imayini, iminyango yezokusebenza kwamakhemikhali kanye ne-chemical ekhethekile ekhethekile ekususeni umlotha kanye ne-sludge esiteshini sikagesi.

Izici Pump:

1. Uchungechunge lwe-ZGB (P) i-Slurry Pumps iyisisekelo, esiteji esisodwa, ukumunca esisodwa, i-cantilever, i-cosiling, casing-casing, centrifugal slurry pump. Ipompo ijikeleza ngokuhamba kwesikhathi kusuka ekupheleni kwedrayivu.

2. Izingxenye ezimanzi ze-ZGB ne-ZGBP Pump ku-Outlet Okufanayo Ubukhulu babo bokufakwa okuhlukile buye bunye futhi okufanayo. Ngengxenye yedrayivu yochungechunge lwe-ZGB (P) i-Slurry Pump, ifreyimu yokuhlukanisa evundlile ngokuthambisa kawoyela kanye namasethi amabili amasethi wokupholisa amanzi ngaphakathi nangaphandle kuye kwamukelwe. Uma kunesidingo, amanzi apholile angahanjiswa. Ukuhlanganiswa okulungiselelwe kwamanzi okupholisa kanye nengcindezi yamanzi apholile kungabonakala etafuleni 1.

3

I-4

Ithebula lokusebenza kwepompo:

|

Isifanekiso | Isivinini n (r / min) | Amandla Q (l / s) | Ikhanda H (m) | Max.Eff. | Npsh | Umgodi Ubuqhwaga (kw) | Umngenzi Dia (mm) | Isisindo sepompo (kg) | Outlet / Inlet (mm) | |

| I-65ZGB | 1480 | 31.7-15.8 | 58-61 | 62.5-47.4 | 4.5-3.0 | 28.8-19.9 | I-390 | Umthandazi we-1850 | 65/80 | |

| 980 | 21.0-10.5 | 25.4-26.7 | 62.5-47.4 | 2.0-1.3 | 8.37-5.8 | |||||

| I-80ZGB | 980 | 56.7-28.3 | 87.5-91.6 | 66.1-48.7 | 5.2-2.7 | 73.7-52.2 | 485 | 2500 | I-80/100 | |

| 740 | 37.5-18.8 | 38.4-40.2 | 66.1-48.7 | 2.3-1.2 | 21.4-15.2 | |||||

| 980 | 52.0-26.0 | 73.7-77.1 | 66.1-48.7 | 4.4-2.3 | 56.8-40.4 | 445 | ||||

| 740 | 34.4-17.2 | 32.3-33.8 | 66.1-48.7 | 1.9-1.0 | 16.5-11.7 | |||||

| 980 | 46.8-23.3 | 59.5-62.3 | 66.1-48.7 | 3.5-1.8 | 41.3-29.2 | 400 | ||||

| 740 | 31.0-15.4 | 26.1-27.3 | 66.1-48.7 | 1.5-0.8 | 12.0-8.4 | |||||

| I-100ZGB | 1480 | 116.7-58.3 | 85.1-91.8 | 77.9-57.4 | 6.0-2.6 | 124.9-91.4 | 500 | 3000 | I-100/152 | |

| 980 | 77.3-38.6 | 37.3-40.3 | 77.9-57.4 | 2.7-1.2 | 36.3-26.6 | |||||

| 1480 | 105-52.5 | 68.9-78.4 | 77.9-57.4 | 4.9-2.1 | 91.0-66.7 | I-450 | ||||

| 980 | 69.5-34.8 | 30.2-32.6 | 77.9-57.4 | 2.1-1.1 | 26.4-19.4 | |||||

| 1480 | 93.4-46.7 | 54.5-58.8 | 77.9-57.4 | 3.8-1.7 | 64.0-46.9 | 400 | ||||

| 980 | 61.8-30.9 | 23.9-25.8 | 77.9-57.4 | 1.7-0.8 | 18.6-13.6 | |||||

| I-150ZGB | 980 | 200-100 | 85.2-90.0 | 77.7-53.3 | 3.8-2.7 | 215.0-165.5 | 740 | I-3450 | 150/200 | |

| 740 | 151.2-75.6 | 48.6-51.3 | 77.7-53.3 | 2.2-1.5 | 92.7-71.3 | |||||

| 980 | 182.4-91.2 | 73.0-77.1 | 77.7-53.3 | 3.3-2.3 | 168.0-129.3 | I-685 | ||||

| 740 | 140.0-70.2 | 41.6-44.0 | 77.7-53.3 | 1.9-1.3 | 74.2-56.8 | |||||

| 980 | 169.2-844.6 | 61.8-65.2 | 77.7-53.3 | 2.8-1.1 | 131.9-101.5 | 630 | ||||

| 740 | 129.6-64.8 | 35.2-37.2 | 77.7-53.3 | 1.6-0.6 | 57.6-44.3 | |||||

| I-200ZGB | 980 | 300.0-150.0 | 89.0-94.2 | 76.3-63.2 | 6.7-2.7 | 342.9-219.1 | 740 | 4000 | 200/250 | |

| 740 | 226.5-113.3 | 50.7-53.7 | 76.3-63.2 | 3.8-1.5 | 147.5-97.3 | |||||

| 980 | 283.8-141.9 | 79.6-84.3 | 76.3-63.2 | 6.0-2.4 | 290.2-185.8 | I-700 | ||||

| 740 | 214.3-107.1 | 45.4-48.1 | 76.3-63.2 | 3.4-1.4 | 125.0-800.0 | |||||

| 980 | 259.5-129.7 | 66.6-70.5 | 76.3-63.2 | 5.0-2.0 | 222.0-141.8 | 640 | ||||

| 740 | 195.9-97.9 | 38.0-40.2 | 76.3-63.2 | 2.9-1.1 | 95.6-61.0 | |||||

| I-250ZGB | 980 | 400.0-200.0 | 84.0-90.1 | 78.2-63.2 | 7.3-3.3 | 421.2-275.6 | 740 | 4500 | 250/300 | |

| 740 | 302.0-151.0 | 47.9-51.4 | 78.2-63.2 | 4.2-1.9 | 181.4-118.7 | |||||

| 980 | 378.4-189.2 | 75.2-80.6 | 78.2-63.2 | 7.1-3.0 | 356.7-233.2 | I-700 | ||||

| 740 | 285.7-142.9 | 42.9-46.0 | 78.2-63.2 | 4.0-1.7 | 153.7-100.5 | |||||

| 980 | 348.6-131.6 | 63.8-68.5 | 78.2-63.2 | 5.5-2.5 | 278.8-137.9 | I-645 | ||||

| 740 | 263.2-99.4 | 36.4-39.1 | 78.2-63.2 | 3.1-1.4 | 120.1-59.4 | |||||

| I-300ZGB | 980 | 533.3-266.7 | 84.3-93.4 | 81.2-68.3 | 6.9-3.5 | 542.8-357.6 | I-760 | 5500 | 300/350 | |

| 740 | 402.7-201.3 | 48.1-53.3 | 81.2-68.3 | 3.9-2.0 | 233.9-154.0 | |||||

| 980 | 493.3-246.7 | 72.1-79.9 | 81.2-68.3 | 5.9-3.0 | 429.4-282.9 | 703 | ||||

| 740 | 372.5-177.9 | 41.1-45.6 | 81.2-68.3 | 3.4-1.7 | 184.8-116.4 | |||||

| 980 | 453.3-226.7 | 60.9-67.5 | 81.2-68.3 | 5.0-2.5 | 333.3-219.7 | I-646 | ||||

| 740 | 342.3-171.2 | 34.5-38.5 | 81.2-68.3 | 2.9-1.4 | 143.4-94.6 |